-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 08, 2024 01:35 Back to list

Exploring the Benefits and Applications of 90 Degree Elbows in Pipeline Systems and Engineering

The Significance of 90-Degree Elbows in Piping Systems

In industrial and plumbing applications, piping systems play a crucial role in the transportation of fluids and gases. Among the various components that comprise these systems, fittings such as elbows are vital for directing flow. Among the types of elbows, the 90-degree elbow stands out as one of the most commonly used. This article explores the significance, applications, manufacturing processes, and advantages of 90-degree elbows in piping systems.

Understanding the 90-Degree Elbow

A 90-degree elbow is a piping fitting that allows the pipe to change direction by 90 degrees. It can be crafted from a variety of materials, including PVC, steel, and copper, making it suitable for various applications. The design of the 90-degree elbow aims to minimize flow resistance while efficiently directing the fluid or gas through the piping system.

Applications of 90-Degree Elbows

The applications of 90-degree elbows are extensive, spanning across numerous industries. In residential plumbing, they are frequently used to divert water flow within walls and ceilings. In industrial settings, 90-degree elbows are crucial in pipelines that transport oil, gas, chemicals, or steam. They facilitate the redirection in piping layouts, ensuring that the system remains compact without unnecessary elongation.

In HVAC systems, the 90-degree elbow is equally crucial. It enables air ducts to navigate tight spaces while maintaining a continuous airflow. In oil refineries and chemical plants, the integrity and efficiency of the piping system are paramount, making reliable fittings like the 90-degree elbow indispensable.

Manufacturing Process

1 1 4 90 degree elbow

The production of 90-degree elbows involves several methods, including casting, forging, and molding. The process begins with selecting the appropriate material based on the application's requirements. For instance, stainless steel elbows are favored for high-pressure applications due to their strength and corrosion resistance.

Once the material is selected, the manufacturing process typically involves shaping the material into a bend. Advanced technology, such as CNC machining and automated welding techniques, ensures precision and uniformity. Rigorous quality control checks follow, ensuring that each elbow meets industry standards and specifications.

Advantages of Using 90-Degree Elbows

One of the primary advantages of 90-degree elbows is their ability to minimize turbulence and pressure drop in the piping system. Properly designed elbows create smoother transitions, promoting efficient flow rates and reducing energy consumption.

Additionally, these fittings are easy to install and integrate into existing piping structures, making them a practical choice for both new installations and retrofitting projects. Their versatility in size and material also allows for customization to meet specific project needs.

Moreover, 90-degree elbows require minimal maintenance. When installed correctly, they can endure high temperatures and pressures, extending the lifecycle of the piping system. This reliability is essential in preventing leaks and reducing downtime, contributing to the overall efficiency of industrial processes.

Conclusion

In conclusion, the 90-degree elbow is a fundamental component of piping systems across various applications. Its ability to facilitate smooth directional changes in fluid flow while minimizing resistance underscores its importance in plumbing and industrial contexts. As technology advances, the manufacturing processes for these fittings will continue to improve, enhancing the performance and reliability of piping systems worldwide. Whether in residential plumbing or large-scale industrial operations, the impact of 90-degree elbows is undeniably significant, ensuring the safe and efficient transport of fluids and gases.

Latest news

-

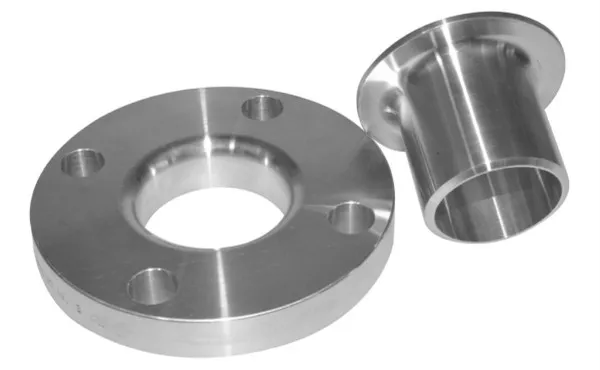

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024