-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 28, 2024 14:39 Back to list

Exploring the Dynamics and Applications of Bomba Slurry in Modern Industrial Processes

Understanding Bomba Slurry A Comprehensive Overview

Bomba slurry, often referred to simply as slurry, plays a critical role in various industrial processes, particularly in mining, construction, and wastewater treatment. The term bomba is derived from the Spanish word for pump, highlighting the crucial aspect of transporting this viscous mixture using specialized equipment. In this article, we will explore what bomba slurry is, its applications, advantages, and the technologies involved in its handling.

What is Bomba Slurry?

At its core, bomba slurry is a mixture of solid particles suspended in a liquid. The solids can vary significantly in size, shape, and composition, including anything from fine dust to larger aggregates, while the liquid is typically water or another fluid capable of suspension. The resulting slurry has unique properties that can be leveraged for various industrial purposes.

Applications of Bomba Slurry

One of the most notable applications of bomba slurry is in the mining industry, where it is used for the transportation of ore, tailings, and other materials. The slurry pipeline method allows for the effective movement of valuable minerals over long distances, significantly reducing the need for heavy truck transportation and minimizing dust and environmental impacts.

In construction, bomba slurry is essential for delivering concrete mixtures to worksites

. The ability to transport concrete in a fluid state enables precision in pouring and minimizes waste. Furthermore, slurry is also utilized in geotechnical applications, such as soil stabilization and grouting, where mixtures are injected into the ground to improve stability.In the realm of wastewater treatment, bomba slurry plays a vital role in the processing of sludge. The mixture helps to manage waste by enabling efficient pumping and transportation of sludge from treatment facilities to disposal sites or for further processing.

bomba slurry

Advantages of Bomba Slurry

The use of bomba slurry offers several advantages across its various applications. One key benefit is the efficiency of transport. By combining solids and liquids, industries can move large volumes of material with less energy compared to transporting solids alone. This results in cost savings and reduces the environmental footprint of operations.

Moreover, the control over material properties through slurry formulation allows for greater flexibility. Adjusting the water-to-solid ratio can tailor the viscosity, making it easier to pump or pour depending on specific project requirements. This adaptability is crucial in dynamic environments where conditions can change rapidly, such as construction sites or mining operations.

Technologies in Bomba Slurry Handling

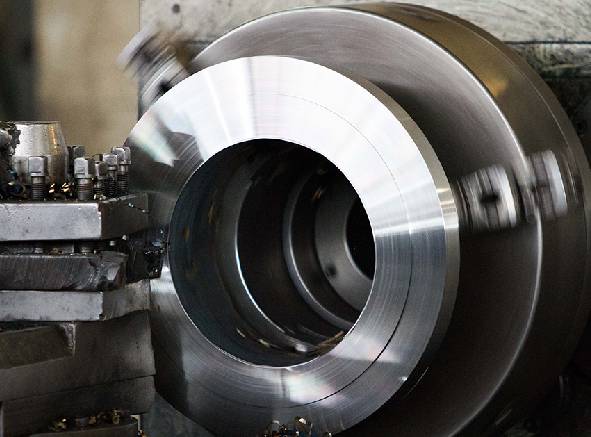

Handling bomba slurry necessitates specialized equipment designed to manage its unique characteristics. Slurry pumps, for instance, are engineered to deal with the abrasive nature of many slurries, with wear-resistant materials extending service life and ensuring reliability.

Additionally, the design of pipelines for slurry transport incorporates considerations for flow dynamics to reduce issues like settling and clogging. Technologies such as centrifugal pumps, positive displacement pumps, and even vacuum pumps are employed based on the specific properties of the slurry being transported.

Conclusion

Bomba slurry is a versatile and indispensable component in various industries, revolutionizing how materials are transported and processed. Its unique properties allow for innovative solutions that enhance operational efficiency, reduce costs, and minimize environmental impacts. As technology continues to advance, the methodologies surrounding bomba slurry will evolve, leading to even greater efficiency and sustainability in industry practices. Understanding and effectively managing bomba slurry is crucial for professionals across sectors that rely on this essential mixture for their operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024