-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 20, 2024 02:01 Back to list

Exploring the Specifications and Applications of API 5L X46 Steel Pipe for Oil and Gas Industry

Understanding API 5L X46 Pipe A Comprehensive Overview

API 5L X46 pipe is a specific grade of steel pipe that plays a critical role in the transportation of oil and natural gas. This pipe is manufactured according to the specifications set forth by the American Petroleum Institute (API), which is a key organization that sets standards for the oil and natural gas industry. The X46 designation indicates that the pipe has a minimum yield strength of 46,000 psi, making it suitable for high-pressure applications.

Composition and Mechanical Properties

The API 5L X46 pipe is typically made from carbon steel. The composition of the steel involves the right balance of carbon, manganese, phosphorus, sulfur, and other alloying elements. This specific composition provides the pipe with excellent strength, durability, and resistance to various environmental factors. The mechanical properties of X46 pipe are crucial for its performance, especially in high-demand applications where structural integrity is a priority.

In addition to its yield strength, the pipe also demonstrates good tensile strength, impact resistance, and ductility. These properties ensure that the pipe can withstand operational stresses encountered in transport pipelines, without succumbing to failure. The ability to bend and shape under stress without breaking makes the API 5L X46 pipe especially useful for various piping configurations.

Applications

API 5L X46 pipes are widely used in the oil and gas industry for transporting crude oil, natural gas, and other substances under high pressure. Their robust specifications make them ideal for use in both onshore and offshore pipelines. The pipe’s resistance to deformation under stress is another reason it is chosen for critical applications such as cross-country pipelines, where they are subjected to extreme environmental conditions.

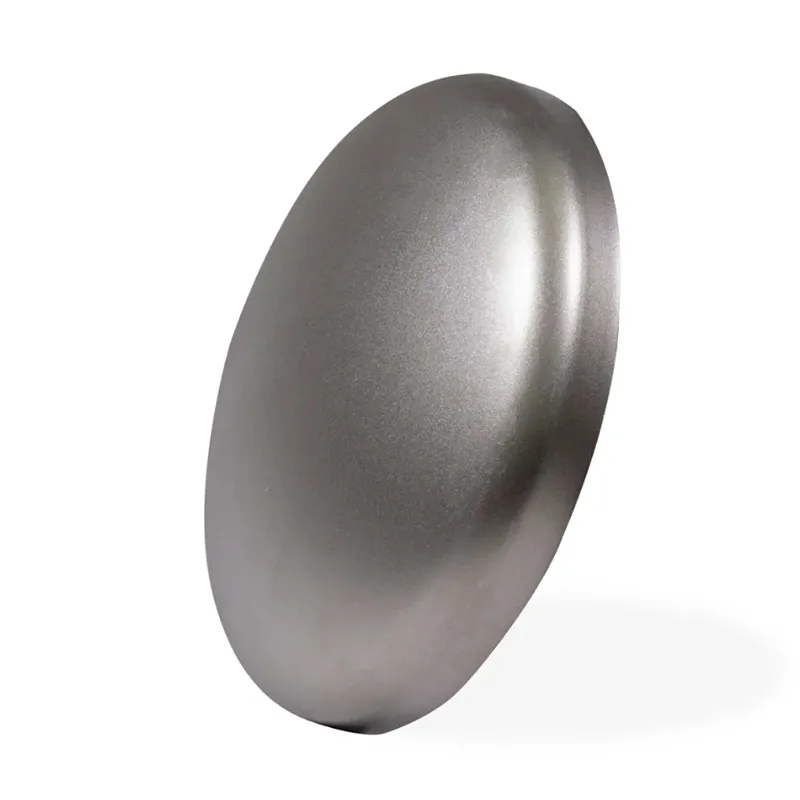

api 5l x46 pipe

Additionally, these pipes are also utilized in water distribution and wastewater management projects, where strength and reliability are just as crucial. The ability to perform under high pressure makes API 5L X46 pipes a versatile choice for a variety of industries, including chemicals, power generation, and construction.

Manufacturing and Standards

The manufacturing process for API 5L X46 pipes involves several key steps, including melting, forming, and welding the steel into the desired shape. Quality control measures are strictly adhered to, ensuring that the pipes meet the requisite standards before leaving the factory. The process is governed by API specifications, which set strict guidelines that manufacturers must follow to ensure quality and reliability.

Furthermore, X46 pipes can be produced in different forms, including seamless and welded varieties. Seamless pipes are manufactured from a solid round steel billet, which is heated and molded into the final product, providing higher resilience against pressure and stress. Welded pipes, on the other hand, are produced by welding together flat steel plates, which can make them more cost-effective for certain applications.

Conclusion

In summary, API 5L X46 pipes are essential components in the oil and gas sector, providing a reliable means of transporting critical resources under high-pressure conditions. Their robust mechanical properties, coupled with stringent manufacturing standards, ensure that they can withstand the challenges posed by harsh environments and maintain structural integrity over time. As the demand for energy continues to grow, the role of API 5L X46 pipes will undoubtedly remain vital, underscoring the importance of these materials in today’s industrial landscape. Understanding the specifications, applications, and manufacturing processes of such pipes is crucial for professionals in the industry to make informed decisions on pipeline solutions.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024