-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 01, 2024 01:16 Back to list

Exploring Type 1 Diabetes Management Strategies and Innovations for Improved Patient Outcomes and Quality of Life

The Impact of EN 1092-1 Type 1 Flanges in Engineering

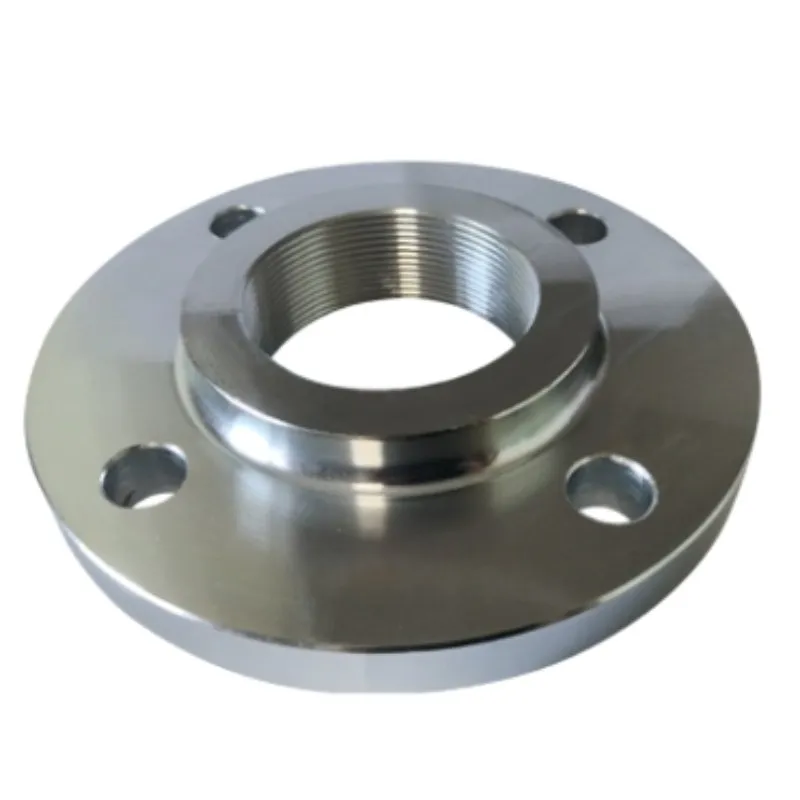

In the world of engineering and manufacturing, standards play a crucial role in ensuring reliability, safety, and interoperability among components. One such standard is EN 1092-1, particularly Type 1 flanges, which are widely used in various industries, including oil and gas, chemical processing, and water treatment. Understanding the significance of these flanges provides insight into their applications and the benefits they bring to engineering practices.

EN 1092-1 is a European standard that specifies the dimensions, tolerances, and materials of circular flanges used in piping systems. Type 1 flanges, specifically, are flat, circular pieces with a raised face that allows for effective sealing when connected to a pipe or another flange. The design is simple yet robust, catering to high pressure and temperature requirements typical in many industrial applications.

The Impact of EN 1092-1 Type 1 Flanges in Engineering

Moreover, the standardized dimensions of these flanges facilitate compatibility across different manufacturers, making it easier for engineers to source components and assemble systems. This aspect is particularly important in projects that require parts from multiple suppliers, as it helps avoid the complications and costs associated with custom manufacturing. The interoperability provided by EN 1092-1 Type 1 flanges promotes efficiency in procurement and reduces lead times, ultimately contributing to project success.

en 1092 1 type 1

The importance of EN 1092-1 Type 1 flanges extends beyond mechanical benefits; they also play a pivotal role in safety. The proper integration of flanges in piping systems is essential to prevent leaks and failures, which can lead to catastrophic incidents, especially in high-stakes industries such as oil and gas. The high-pressure ratings associated with these flanges ensure that they can withstand significant stress without compromising structural integrity. Consequently, adherence to standards like EN 1092-1 is critical in mitigating risks and ensuring safe operations.

In addition to safety, the uniformity of EN 1092-1 Type 1 flanges assists in maintenance and inspection procedures. With flanges being standardized, maintenance teams can easily identify and replace components without extensive retraining or adjustments. Regular inspections can be conducted efficiently, allowing for timely maintenance and reducing unplanned downtime.

Furthermore, as industries move towards sustainability, the standardization provided by EN 1092-1 can aid in promoting eco-friendly practices. Utilizing standardized components can streamline recycling processes and the use of sustainable materials in flange production. This shift not only reduces waste but also encourages manufacturers to innovate and create more environmentally friendly products.

In conclusion, EN 1092-1 Type 1 flanges represent a vital component in modern engineering and manufacturing. Their solid design, material versatility, compatibility, and safety aspects play a significant role in various industries. As the engineering landscape continues to evolve, the importance of adhering to established standards like EN 1092-1 will only grow, fostering a culture of safety, efficiency, and sustainability in the design and implementation of piping systems. By recognizing the value of these flanges, engineers can contribute to more reliable and responsible engineering practices in their respective fields.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024