-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 21, 2024 11:36 Back to list

flange 8 inch ansi 150

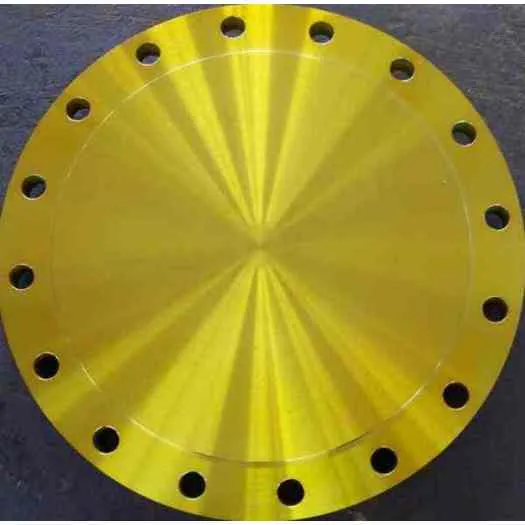

Understanding 8-Inch ANSI 150 Flanges A Comprehensive Overview

Flanges play a critical role in various piping systems used across industries such as oil and gas, water treatment, and chemical processing. Among the various types of flanges, the 8-inch ANSI 150 flange stands out due to its compatibility with standard piping components and its effectiveness in maintaining system integrity under pressure.

Understanding 8-Inch ANSI 150 Flanges A Comprehensive Overview

One of the primary materials used for ANSI 150 flanges is carbon steel, although they can also be manufactured from stainless steel, ductile iron, or other materials depending on the application requirements. The choice of material influences factors such as corrosion resistance, strength, and thermal conductivity. For instance, stainless steel flanges are preferred in environments where corrosion is a significant concern, whereas carbon steel flanges are often used for more general applications.

flange 8 inch ansi 150

When it comes to installation, proper alignment and tightening of bolts are essential to achieve a leak-proof seal. The flange must be mated with a compatible pipe, often accompanied by gaskets to ensure a tight seal. It’s crucial to follow the recommended torque specifications to prevent over-tightening, which can lead to flange damage or failure.

Another important aspect to consider is the compatibility of the flange with other components in the system. This includes factors such as flange type (e.g., raised face, flat face, or ring-type joint) and bolt pattern. Ensuring that the 8-inch ANSI 150 flange meets the specifications of the connected piping components is vital for achieving optimal system performance.

In conclusion, the 8-inch ANSI 150 flange is a robust and versatile component that plays a crucial role in many industrial applications. Its ability to maintain structural integrity under pressure while being compatible with a range of materials and sealing methods makes it a popular choice in engineering projects. Whether you are involved in design, installation, or maintenance, understanding the characteristics and applications of these flanges is essential for ensuring reliable and efficient system operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024