-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 10, 2024 21:09 Back to list

Understanding ANSI 1500 Flanges and Their Applications in Industry

Understanding ANSI 1500 Flanges Design, Applications, and Benefits

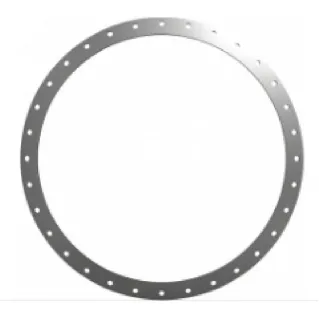

Flanges are mechanical components used to connect pipes, valves, pumps, and other equipment to form a piping system. They serve multiple purposes, from providing a removable connection to allowing for pressure containment. Among the various flange standards, ANSI (American National Standards Institute) flanges are widely recognized in industries around the world. Specifically, ANSI 1500 flanges are designed to handle high-pressure applications, making them essential in various fields such as oil and gas, chemical processing, and power generation.

What is ANSI 1500?

The term ANSI 1500 refers to the pressure class rating of flanges that can safely withstand a pressure of up to 1500 pounds per square inch (psi). This rating indicates the maximum pressure that the flange can handle under specified temperature conditions. ANSI flanges are categorized into different classes (such as 150, 300, 600, 900, 1500, and 2500), with the number indicating the maximum pressure in psi at a given temperature. ANSI 1500 flanges, therefore, are engineered to support high levels of pressure, making them suitable for demanding industrial environments.

Design Specifications

ANSI 1500 flanges are available in various materials, including carbon steel, stainless steel, and alloys, which allows for compatibility with a wide range of corrosive and high-temperature applications. These flanges come in different shapes, including raised face (RF), flat face (FF), and ring-type joint (RTJ), among others. The design also incorporates specific bolt hole patterns and dimensions, following the standards set by ANSI B16.5 or B16.47, ensuring that they can be effectively bolted to matching pipe ends or other flanges.

The dimensions of ANSI 1500 flanges are crucial, as they not only dictate the type of connection that can be achieved but also play a role in the overall flow characteristics of the system. A well-designed flange allows for smooth fluid flow, minimizing pressure drops and enhancing the efficiency of piping systems.

Applications of ANSI 1500 Flanges

Due to their ability to handle high pressures, ANSI 1500 flanges are commonly used in various applications, including

1. Oil and Gas Industry These flanges are frequently employed in upstream and downstream operations, including drilling rigs, refining processes, and pipeline systems.

2. Chemical Processing In environments where corrosive substances are handled, ANSI 1500 flanges provide the necessary strength and resistance, ensuring system integrity.

flange ansi 1500

3. Power Generation High-pressure steam systems in power plants often utilize ANSI 1500 flanges to maintain safety and operational efficiency.

4. Water Treatment Facilities ANSI 1500 flanges can manage high-pressure conditions found in treatment and distribution systems, playing a vital role in ensuring water safety and quality.

Benefits of Using ANSI 1500 Flanges

Using ANSI 1500 flanges comes with several advantages

- Strength and Reliability These flanges are designed to withstand high pressures, ensuring the integrity and safety of piping systems.

- Versatility ANSI 1500 flanges can be used in a variety of industries, making them a versatile choice for engineers and contractors.

- Standardization ANSI standards provide a common reference point for manufacturers and users, ensuring compatibility and simplifying the procurement process.

- Reduced Risk of Leaks Properly installed ANSI 1500 flanges create tight seals, which helps to minimize the risk of leaks and potential failures that could lead to hazardous situations.

Conclusion

In summary, ANSI 1500 flanges play a crucial role in high-pressure piping systems across numerous industries. Their design, specifications, and robust performance make them indispensable for ensuring safety and efficiency. Choosing the right flange and ensuring proper installation is essential for the longevity and reliability of piping systems, showcasing the importance of adhering to ANSI standards in industrial applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024