-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 18, 2024 13:59 Back to list

Understanding ANSI 2500 Flange Standards and Their Applications in Industrial Settings

Understanding ANSI 2500 Flanges A Comprehensive Overview

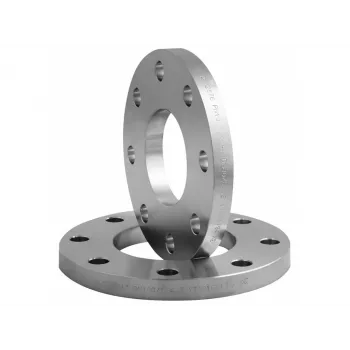

Flanges are crucial components in the piping industry, used to connect two pipe sections securely while allowing for maintenance or modification when necessary. Among the various flange standards available, ANSI (American National Standards Institute) has established a recognized system for flanges, including the highly regarded ANSI 2500 flange. This article aims to provide an in-depth understanding of ANSI 2500 flanges, including their specifications, applications, benefits, and installation considerations.

What is an ANSI 2500 Flange?

ANSI 2500 flanges refer to flanges designed to support a specified pressure class of 2500 pounds per square inch (PSI) at ambient temperature. These flanges are integral parts of high-pressure systems and are manufactured in accordance with ANSI B16.5 standards, which detail dimensions, tolerances, and pressure-temperature ratings for flanges used in piping applications.

The ANSI 2500 flange is typically made from various materials, including carbon steel, stainless steel, and alloy materials, allowing them to withstand harsh environments and high-pressure conditions. These flanges can be found in various types, including slip-on, threaded, blind, and weld neck, each serving different needs in piping configurations.

Applications of ANSI 2500 Flanges

Given their high-pressure capacity, ANSI 2500 flanges are predominantly used in industries such as

1. Oil and Gas In upstream and downstream operations, ANSI 2500 flanges can safely handle the pressures involved in oil extraction and processing.

2. Chemical Processing The chemical industry often requires robust pipeline systems capable of enduring high pressures and temperatures. ANSI 2500 flanges are suitable for corrosive materials due to their durable material options.

3. Power Generation In power plants, particularly those working with steam systems, ANSI 2500 flanges play a critical role in connecting pipes and ensuring system integrity.

4. Water Treatment Treatment facilities utilize these high-pressure flanges in various applications to ensure efficient transport and processing of water.

Advantages of ANSI 2500 Flanges

flange ansi 2500

1. Durability The materials used in ANSI 2500 flanges provide excellent resistance to wear and tear, making them suitable for many demanding applications.

2. Versatility With various types available—such as blind, slip-on, and weld neck—ANSI 2500 flanges can be adapted to various piping needs and configurations.

3. Safety Designed to handle severe conditions, ANSI 2500 flanges contribute significantly to system safety, reducing the risk of leaks or failures in high-pressure systems.

4. Standardization As ANSI standards are widely accepted, the compatibility and interchangeability of ANSI 2500 flanges with other piping components are highly reliable, simplifying maintenance and replacement.

Installation Considerations

When installing ANSI 2500 flanges, several factors must be considered to ensure a secure and leak-free connection

1. Surface Preparation Flange surfaces need to be clean and free from debris. Proper gasket selection is also crucial for preventing leaks.

2. Alignment Flanges should be properly aligned to avoid undue stress on the piping system. Misalignment can lead to premature failure.

3. Torque Specifications Adhering to the recommended torque specifications is essential. Over-tightening can damage the flange, while under-tightening may result in a leak.

4. Regular Inspections High-pressure systems are subject to wear over time. Regular inspections of flanges are important to identify potential issues before they lead to system failure.

Conclusion

Highlighting the critical role of ANSI 2500 flanges in various industries underscores the importance of proper selection, installation, and maintenance. Their strength and reliability make them a preferred choice for high-pressure applications, ensuring the integrity and safety of piping systems. Whether in oil and gas, chemical processing, power generation, or water treatment, ANSI 2500 flanges continue to be a vital component in modern engineering solutions. Understanding their specifications and applications can greatly enhance the efficacy and safety of piping systems in today’s industrial landscape.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024