-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 11, 2024 00:38 Back to list

flange ansi 900

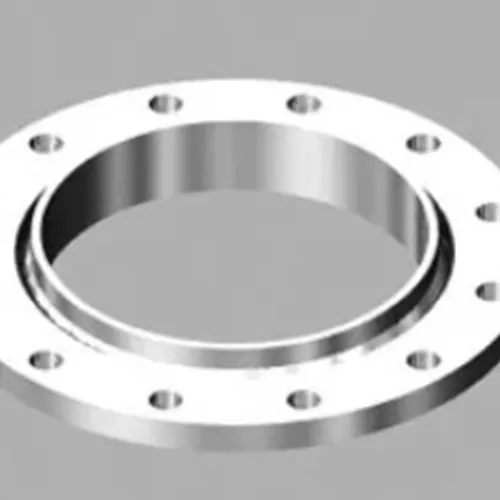

Understanding ANSI 900 Flanges A Comprehensive Overview

Flanges play a crucial role in piping systems, providing a reliable method for joining two sections of pipe and allowing for easy disassembly. Among the various standards set for flanges, the ANSI 900 flange stands out due to its specific pressure ratings and applications. This article delves into the characteristics, uses, and importance of ANSI 900 flanges in industrial applications.

What is ANSI 900 Flange?

The term ANSI refers to the American National Standards Institute, which sets standards for various equipment, including flanges. The 900 designation indicates the pressure class rating of the flange, meaning that these flanges are capable of withstanding a pressure of up to 900 psi (pounds per square inch) in typical service conditions. ANSI 900 flanges are designed to ensure safe and reliable connections in systems subjected to high pressures.

Material Composition

ANSI 900 flanges are manufactured from various materials, including carbon steel, stainless steel, and alloys. The choice of material typically depends on the application's specific requirements, including the type of fluid being transported, temperature, and environmental conditions. For instance, stainless steel ANSI 900 flanges are often used in corrosive environments due to their resistance to rust and corrosion.

Design Specifications

The design of ANSI 900 flanges adheres to the American National Standards Institute standards, ensuring consistency and safety in their use. These flanges typically feature a flat face or raised face, with bolt holes drilled to allow for the attachment to pipes or other equipment. The dimensions, including bolt circle diameters and thickness, are standardized to ensure compatibility with other ANSI-rated components.

flange ansi 900

Applications

ANSI 900 flanges are commonly used in various industries, including oil and gas, chemical processing, water treatment, and HVAC systems. Their ability to handle high-pressure applications makes them particularly valuable in systems where pressure fluctuations occur. For example, in the oil and gas sector, ANSI 900 flanges are routinely utilized in pipelines that transport crude oil and natural gas, ensuring safe and secure connections that can withstand the rigors of extreme pressure conditions.

Advantages

One significant advantage of using ANSI 900 flanges is their reliability. With a robust design and high-pressure rating, they provide assurance against leaks and failures in critical systems. Additionally, the standardization of ANSI flanges facilitates easy interchangeability and maintenance, reducing downtime in industrial operations. Because they can be installed and removed with relative ease, ANSI 900 flanges contribute to efficient maintenance practices in various applications.

Considerations for Use

While ANSI 900 flanges are durable and reliable, it's essential to consider proper installation and maintenance practices to ensure their longevity and effectiveness. Proper torque specifications must be adhered to when tightening bolts, and regular inspections should be conducted to identify any signs of wear or damage. Furthermore, it is crucial to select the appropriate flange based on the specific application's pressure and temperature requirements.

Conclusion

In conclusion, ANSI 900 flanges are vital components in high-pressure piping systems, providing safe and efficient connections in a wide range of industries. Their robust construction, standardized design, and material versatility make them an ideal choice for applications requiring reliable performance under challenging conditions. By understanding the characteristics and applications of ANSI 900 flanges, engineers and technicians can make informed decisions that enhance the safety and efficiency of their piping systems. As the demand for high-pressure applications continues to grow, the significance of ANSI 900 flanges in modern engineering will undoubtedly increase.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024