-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 09, 2024 21:45 Back to list

Understanding the Benefits and Applications of Flanged Fittings in Piping Systems

Understanding Flanged Fittings A Comprehensive Overview

Flanged fittings play a pivotal role in various industrial applications, serving as essential components in piping systems. These fittings are crucial for connecting pipes, valves, pumps, and other equipment to facilitate the smooth transportation of fluids and gases. We will explore the design, types, advantages, and applications of flanged fittings, highlighting their significance in modern engineering and construction.

What Are Flanged Fittings?

Flanged fittings consist of two parts a flat piece of metal, known as the flange, and the fitting itself. The flange is typically welded or bolted to the pipe or fitting, creating a secure connection that can withstand high pressures and temperatures. This design allows for easy assembly and disassembly, making maintenance and inspection straightforward.

Flanged fittings are often made from a variety of materials, including carbon steel, stainless steel, cast iron, and plastic, each selected based on the specific demands of the application. The choice of material can affect the corrosion resistance, strength, and durability of the fitting, which are critical factors in structural integrity.

Types of Flanged Fittings

Flanged fittings come in various types, each serving distinct purposes within a piping system

1. Flat Flange The most common type, flat flanges are used to connect two sections of pipe. They have a flat surface and are bolted together with a gasket in between to ensure a leak-proof seal.

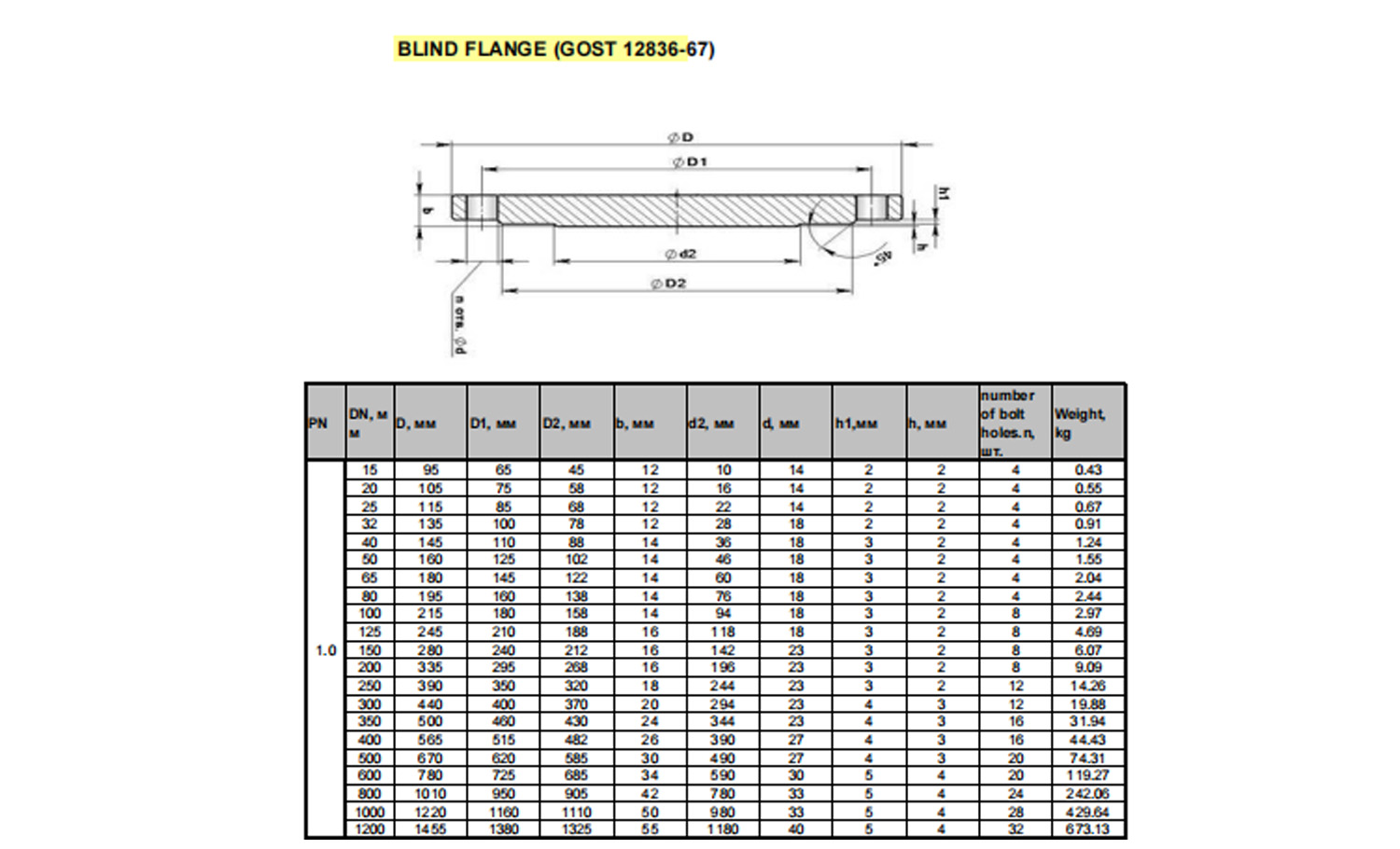

2. Blind Flange Used to close off a piping system, blind flanges do not have a hole in the center. They are essential for maintenance operations, allowing sections of a pipeline to be sealed off from fluid flow.

3. Slip-On Flange These flanges are slipped over the pipe end and then welded in place. Slip-on flanges are easy to install and are commonly used in applications that require a strong but flexible connection.

4. Weld Neck Flange Designed with a long neck that provides a smooth transition from the pipe to the flange, weld neck flanges are ideal for high-pressure applications. They are welded at the joint for added strength.

5. Socket Weld Flange Similar to slip-on flanges, socket weld flanges are inserted into the pipe and then welded. They are typically used for smaller diameter pipes and high-pressure scenarios.

6. Threaded Flange These flanges have internal threads allowing them to be screwed onto the pipe. They are often used in applications where welding is not feasible.

flanged fitting

Advantages of Flanged Fittings

Flanged fittings offer numerous benefits that make them an attractive option in piping systems

.1. Ease of Installation The bolt connection allows for simple assembly and disassembly, facilitating quick installation.

2. Versatility With various types available, flanged fittings can be used in a multitude of settings and conditions, from high-pressure systems to corrosive environments.

3. Leak Prevention When installed correctly with a suitable gasket, flanged fittings provide reliable leak-proof connections, which is critical in maintaining the integrity of piping systems.

4. Maintenance and Inspection The flange design allows for easily accessible connections, enabling efficient maintenance and inspection practices. This is particularly beneficial in complex systems where full disassembly may be impractical.

5. Strength and Durability Flanged fittings are designed to withstand high pressures and temperature variations, making them suitable for use in critical applications.

Applications

Flanged fittings are widely used across various industries, including

- Oil and Gas For transporting crude oil, natural gas, and refined products. - Chemical Processing In chemical plants where corrosive substances are handled. - Water Treatment Used in systems designed for pumping and treating water in municipal facilities. - HVAC Systems As part of heating and cooling systems to connect air ducts and other components.

Conclusion

Flanged fittings are a fundamental component in modern piping systems, offering reliability, ease of use, and versatility. Their ability to facilitate secure connections in various industrial applications cannot be overstated. Understanding the different types of flanged fittings, their advantages, and their uses is crucial for engineers and professionals in ensuring efficiency and safety in multiple sectors. Whether in oil refineries, chemical plants, or water treatment facilities, flanged fittings will continue to be a staple of effective engineering practices.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024