-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 12, 2024 01:08 Back to list

Flanged Needle Valve Design and Applications in Fluid Control Systems

Understanding Flanged Needle Valves Design, Functionality, and Applications

Flanged needle valves are integral components in various industrial systems, designed to precisely control the flow of fluids in pipelines. When it comes to flow regulation, the choice of the valve type plays a crucial role in the efficiency and safety of the entire system. A flanged needle valve is particularly favored for its ability to provide fine control over flow rates, making it ideal for applications where precise measurements are necessary.

Design Features

The distinctive design of flanged needle valves sets them apart from other valve types. The key characteristic of a needle valve is its long, tapered seat that allows for controlling the flow rate with exceptional accuracy. The flanged aspect of these valves refers to the flange connections at both ends, which facilitate easy installation and maintenance. Flanges are flat pieces of metal or other materials that provide a stable interface for securing the valve to pipes using bolts and nuts.

Typically constructed from durable materials such as stainless steel, brass, or carbon steel, flanged needle valves ensure reliability and longevity, even in harsh conditions. Their design typically incorporates a handwheel or lever mechanism that allows operators to turn the valve stem, which raises or lowers the tapered needle plug within the body of the valve, thus regulating fluid flow.

Functionality

Flanged needle valves excel at offering precise control over liquid or gas flow. This is achieved through the fine threading of the valve stem, which allows for incremental adjustments. Unlike ball or gate valves that can fully open or close the flow with little variation, needle valves are designed for throttling, enabling operators to adjust the opening to very fine degrees. This functionality makes them well-suited for applications such as fuel line regulation, instrument calibration, and in systems where accurate dosing of fluids is critical.

The flow through a flanged needle valve can be closely monitored and adjusted, making them an essential component in many chemical processing and laboratory settings. Moreover, they can handle a range of pressures and temperatures, depending on their construction materials, making them versatile for different applications.

Applications

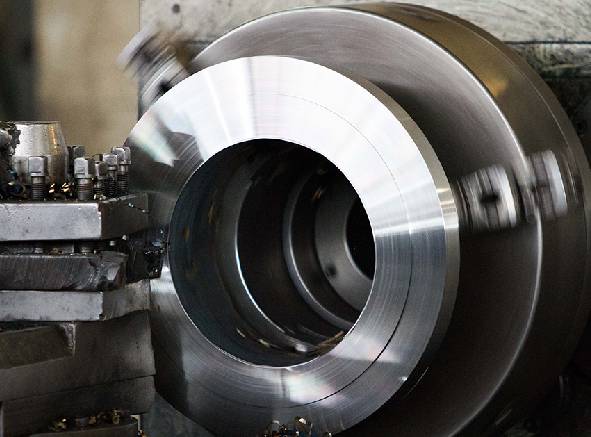

flanged needle valve

Flanged needle valves are widely utilized in various industries due to their precise control capabilities and robust design. Some key applications include

1. Oil and Gas Industry Needle valves are utilized to regulate the flow of crude oil, natural gas, and various byproducts in extraction and refining processes. Their ability to withstand high pressures and corrosive substances makes them ideal for these applications.

2. Chemical Processing In chemical manufacturing, precision is vital for achieving desired reactions. Flanged needle valves are employed in reactors and pipelines to manage the flow of reactants and products meticulously.

3. Water Treatment In municipal and industrial water treatment plants, these valves help control the flow of treatments and chemicals, ensuring optimal water quality.

4. Pharmaceuticals The pharmaceutical industry demands strict adherence to standards of cleanliness and precision. Flanged needle valves are extensively used in processes that require accurate control of liquid flow, ensuring consistency and quality in drug formulation.

5. Laboratory Applications In laboratory settings, flanged needle valves often play a role in experimental setups, enabling researchers to control the flow of gases and liquids in an accurate manner.

Conclusion

Flanged needle valves are invaluable components in many industrial applications, offering a combination of precision, durability, and versatility. Their unique design allows for meticulous flow control, essential in industries ranging from oil and gas to pharmaceuticals. As technology continues to advance, the design and application of these valves may evolve, but their fundamental purpose of providing accurate flow regulation will undoubtedly remain critical to countless processes. Whether in managing a large-scale chemical plant or regulating a laboratory experiment, flanged needle valves continue to play a pivotal role in fluid control systems around the world.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024