-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 13, 2024 13:32 Back to list

flanged plug

The Flanged Plug An Essential Component in Modern Engineering

In modern engineering and construction, the flanged plug plays a crucial role, particularly in piping and fluid management systems. Understanding its design, functionality, and applications can enhance the efficiency and safety of various industrial operations.

A flanged plug is essentially a type of fitting that features a flange—an external rib or rim that enables it to be securely attached to another component. Typically found at the end of pipes, hoses, or tubes, flanged plugs are designed to provide a leak-proof seal that can handle various pressures and temperatures. The flanged design allows for easy installation and removal, which is invaluable in many industrial scenarios.

One of the primary advantages of using flanged plugs is their compatibility with different materials and systems

. They can be made from various substances, including metals, plastics, and composites, catering to a range of industries, from oil and gas to pharmaceuticals and food processing. This versatility makes them ideal for any situation where a strong, durable connection is necessary.flanged plug

Flanged plugs are particularly significant in systems that require frequent maintenance or the ability to isolate sections of piping. By utilizing flanged connections, engineers can easily disassemble sections of the piping for inspection, repair, or replacement without disrupting the entire system. This ease of access is critical in ensuring operational efficiency and minimizing downtime.

In terms of safety, flanged plugs contribute to the integrity of the system they are part of. A well-sealed flanged plug can prevent leaks that could lead to hazardous material exposure, environmental contamination, or even catastrophic failures. Therefore, selecting the right type of flanged plug, along with appropriate gaskets and sealing materials, is essential for ensuring a secure fit.

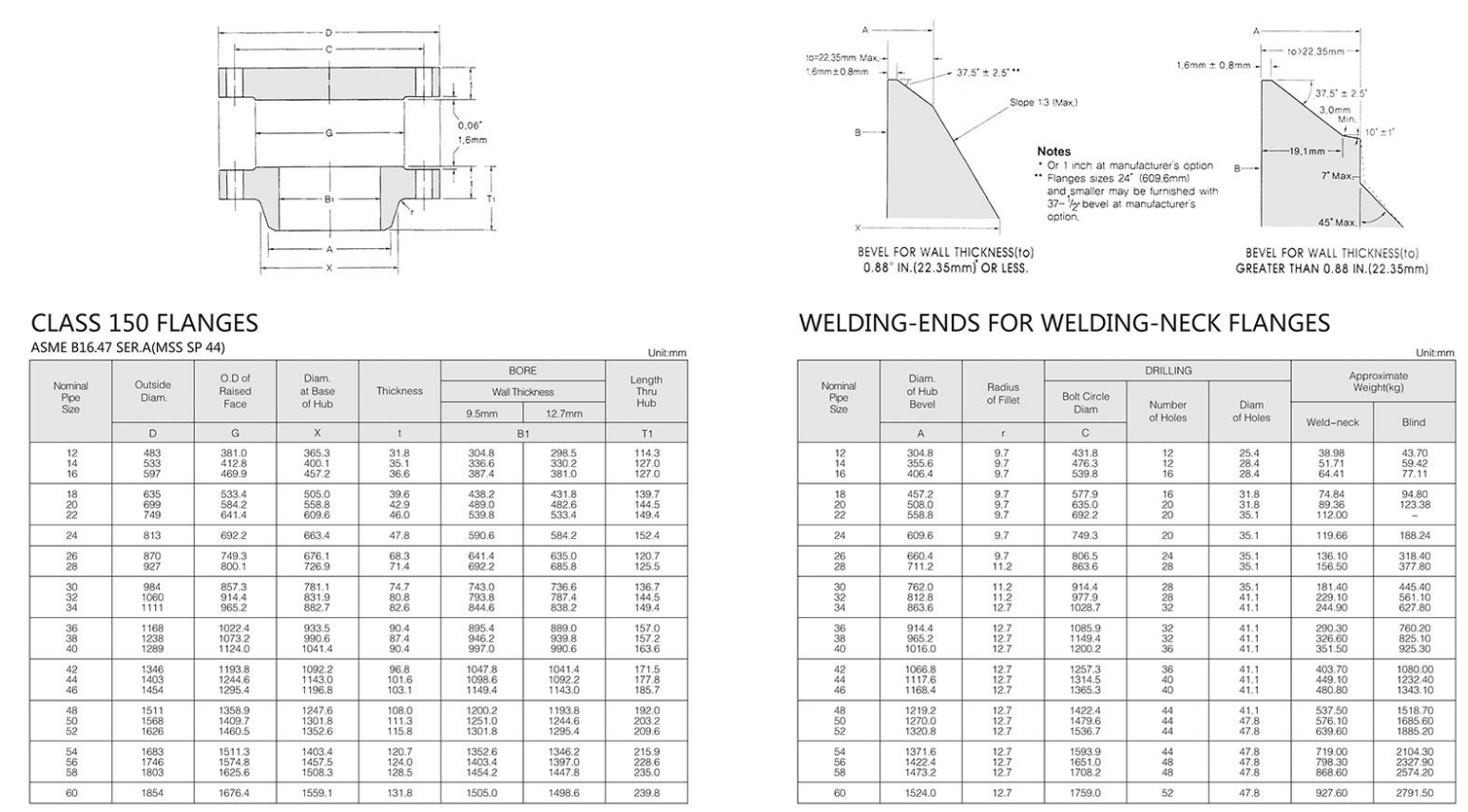

Moreover, the design specifications of flanged plugs are often dictated by industry standards, which ensures their reliability and performance across various applications. From standard dimensions to specific material grades, adhering to these guidelines helps in maintaining consistency and safety in engineering practices.

In conclusion, the flanged plug is an indispensable component in contemporary engineering. Its ease of installation, compatibility with diverse materials, and safety features make it a preferred solution for fluid management systems in many industries. As technology advances and industries evolve, the role of flanged plugs will undoubtedly continue to expand, highlighting their importance in maintaining efficient and secure operations. Understanding these components is essential for engineers and maintenance professionals alike, as they work towards creating and sustaining effective industrial systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024