-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 20, 2024 17:51 Back to list

flange in china

Flanges in China A Comprehensive Overview

Flanges are essential components used in various industries, primarily for the purpose of connecting pipes, valves, pumps, and other equipment to form a piping system. In China, the manufacturing and supply of flanges have seen significant growth over the past few decades, making the country one of the largest producers and exporters of flanges in the world. This article explores the types, manufacturing processes, applications, and market trends related to flanges in China.

Types of Flanges

Flanges come in various types and standards, catering to different industry requirements. The most common types of flanges produced in China include

1. Weld Neck Flanges These flanges are characterized by a gradual thickening of the neck to ensure strength and stability. They are typically used in high-pressure applications.

2. Blind Flanges Used to seal the end of a piping system, blind flanges do not have a bore and are ideal for pressure vessel applications.

3. Slip-On Flanges These flanges are slid over the pipe and then welded in place, making them easier to use and install in low-pressure applications.

4. Socket Welding Flanges Designed for small diameter pipes, these flanges accept the pipe into a socket and are welded around the outer edge.

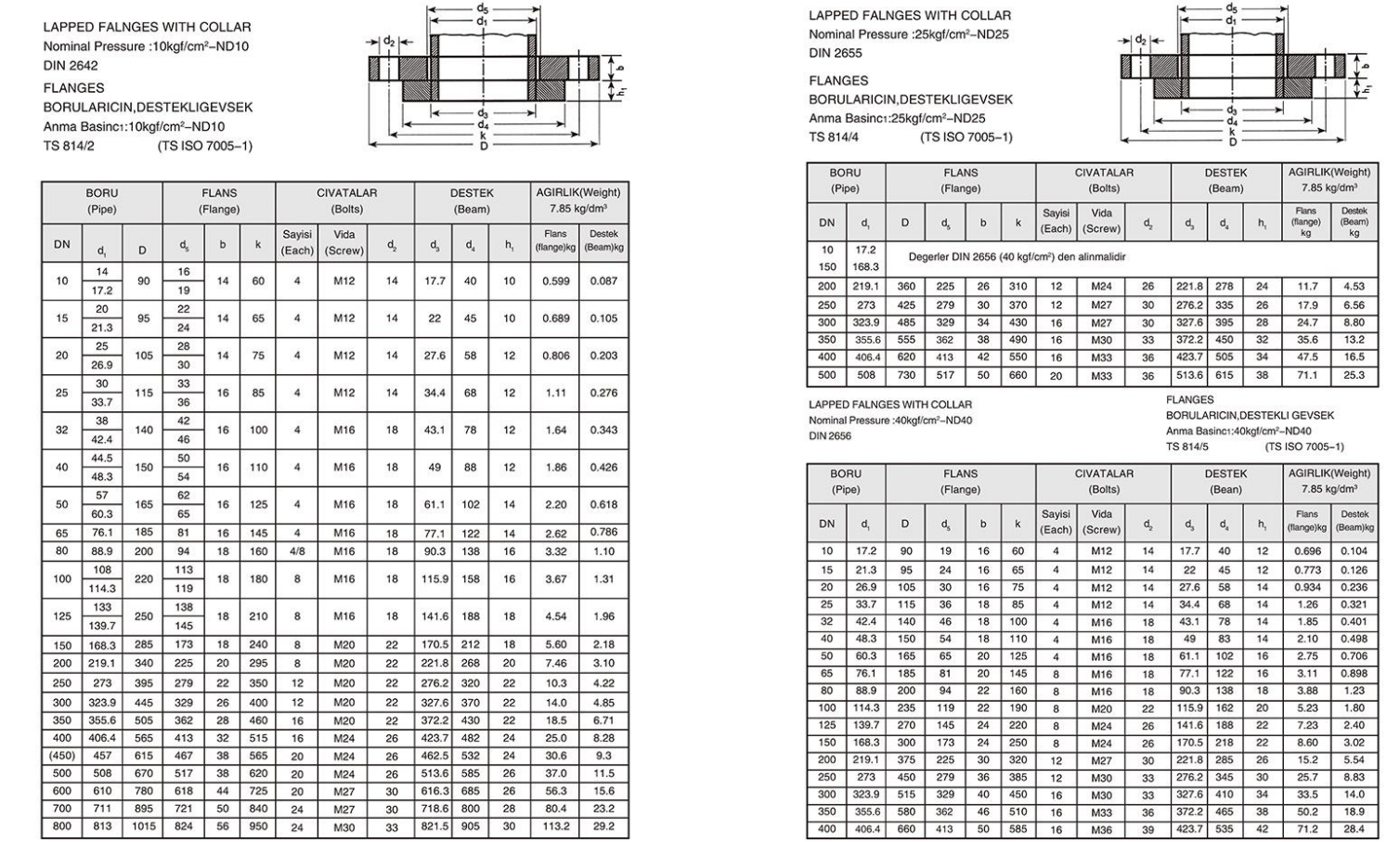

5. Lap Joint Flanges Used with a stub end, these flanges are easy to align and are commonly found in applications that require frequent dismantling.

Manufacturing Processes

The manufacturing of flanges in China involves several key processes, including forging, casting, machining, and finishing.

1. Forging This process involves shaping the flange from a solid piece of metal by applying compressive forces. Forged flanges are known for their superior mechanical properties and are often used in high-pressure and high-temperature applications.

2. Casting In this method, molten metal is poured into molds to create the desired shape. Casting is often used for producing large flanges and those with complex designs.

flange in china

3. Machining After forging or casting, flanges undergo machining to achieve precise dimensions and surface finish. This process includes drilling holes, cutting threads, and grinding surfaces.

4. Finishing Finally, flanges may undergo various finishing processes, such as galvanizing or coating, to enhance their corrosion resistance and durability.

Applications of Flanges

Flanges manufactured in China find applications across numerous sectors, including

- Oil and Gas Flanges are extensively used in pipelines for transporting oil and natural gas, where durability and pressure integrity are critical.

- Chemical Processing Flanges play a vital role in the chemical industry, connecting various processing equipment and ensuring safe operations.

- Power Generation In power plants, flanges are used in piping systems that transport steam and water, where high temperature and pressure conditions are prevalent.

- Water Treatment Flanges are crucial in municipal water and wastewater treatment facilities for the reliable connection of pipes.

Market Trends

China's flange market is characterized by both opportunities and challenges. With the rapid growth of infrastructure development and industrialization, the demand for flanges continues to rise. The Chinese government’s investment in transportation, energy, and manufacturing sectors further propels this demand.

On the other hand, manufacturers face challenges such as fluctuating raw material prices, competition from low-cost imports, and pressure to adhere to international quality standards. To remain competitive, many Chinese flange manufacturers are investing in advanced manufacturing technologies and quality control processes.

Conclusion

Flanges are indispensable components in the global industrial landscape, and China stands at the forefront of their production and supply. With a wide range of types and applications, combined with robust manufacturing capabilities, China is poised to meet the growing domestic and international demand for flanges. As technology and industry standards evolve, the Chinese flange market is likely to continue its growth trajectory, maintaining its significant role in the global industrial supply chain.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024