-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 19, 2024 03:09 Back to list

flange slip on ansi b16 5

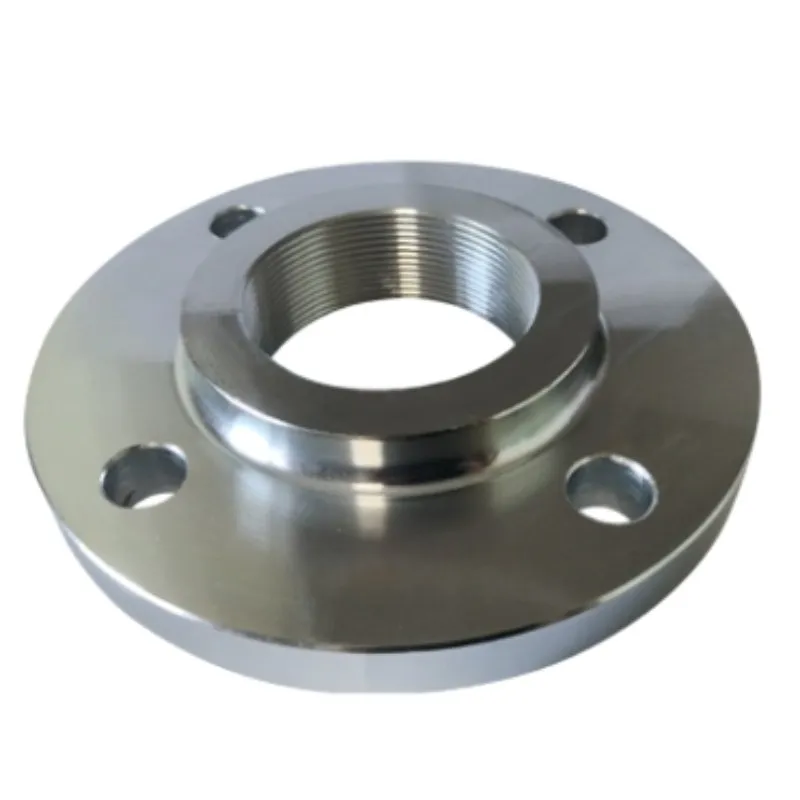

Flange Slip-On ANSI B16.5 A Comprehensive Overview

Flanges are critical components in piping systems, providing a reliable means of connecting pipes, valves, and equipment. Among the various types of flanges, the slip-on flange is particularly popular due to its ease of installation and versatility. ANSI B16.5 is a standard that specifies the dimensions, tolerances, and materials for these flanges, ensuring that they meet stringent performance requirements required in various industries.

Flange Slip-On ANSI B16

.5 A Comprehensive OverviewAccording to ANSI B16.5, slip-on flanges are available in a variety of materials, including carbon steel, stainless steel, and alloy steel, allowing for compatibility with different fluids and operating conditions. The standard also defines several pressure classes (such as 150, 300, 600, and 900) to accommodate various pressure and temperature conditions. Thus, engineers and designers can select the appropriate flange type tailored to the specific requirements of their applications.

flange slip on ansi b16 5

One of the key advantages of slip-on flanges is their adaptability. They can be utilized in a wide range of applications, from oil and gas pipelines to chemical processing plants. However, it is important to note that while slip-on flanges are tolerant to misalignment, they may not be suitable for high-pressure applications as the design can lead to increased stress concentration compared to other flange types, such as welded neck flanges.

Furthermore, when considering the installation of slip-on flanges, it is crucial to account for the correct flange diameter and thickness. The ANSI B16.5 standard provides detailed specifications on these parameters, ensuring that the flanges selected will not only fit properly but also provide the necessary support under operational conditions.

Installation procedures must also adhere to best practices to maximize the effectiveness of the slip-on flange. This includes proper cleaning of the contact surfaces before welding, ensuring the welds are uniform, and implementing proper heat treatment if required. Flange maintenance is equally important; regular inspection for signs of wear, corrosion, or leaks can prevent costly downtimes and enhance system reliability.

In conclusion, the slip-on flange according to ANSI B16.5 provides an effective solution for piping system connections across various industries. Its design promotes ease of installation and reliability, making it a preferred choice among engineers and technicians. When selecting and using these components, adhering to standards and best practices ensures optimal performance and longevity, benefiting industrial processes in the long run.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024