-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 11, 2024 01:56 Back to list

flange taps

Understanding Flange Taps A Comprehensive Guide

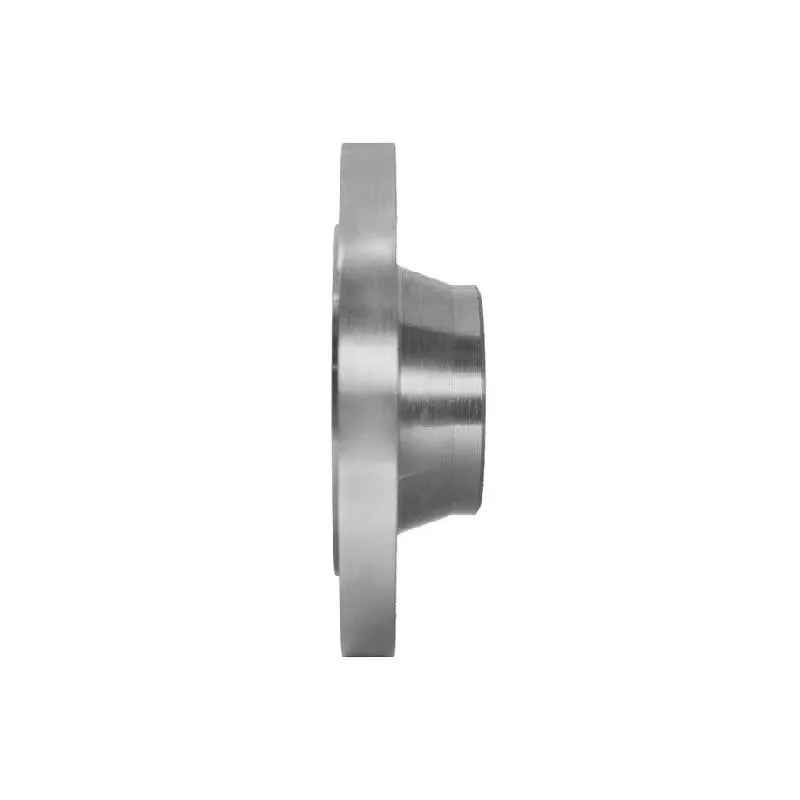

In the realm of mechanical engineering and piping design, the term flange taps refers to a particular type of connection used in fluid systems. Flange taps are integral components that facilitate joins between different sections of pipes or equipment. In this article, we will explore what flange taps are, their applications, advantages, and how they are typically installed and maintained.

What are Flange Taps?

Flange taps are mounted on the flanges of pipes, which are flat surfaces joined by bolts that create a seal. These taps allow for the insertion of measuring devices or sampling components in piping systems. They can be found in a variety of materials including stainless steel, carbon steel, and plastic, catering to different system requirements.

Flange taps typically feature a threaded outlet, enabling the attachment of other devices such as pressure gauges, thermometers, and sampling valves. This versatility is crucial in many industrial applications where monitoring and adjustments are necessary for system performance.

Applications of Flange Taps

The use of flange taps spans multiple industries. In chemical processing, flange taps facilitate the sampling of materials without requiring the entire system to be opened. This capability is essential for maintaining product quality and conducting necessary tests.

In the oil and gas industry, flange taps are used for pressure monitoring. Accurate pressure readings are vital for ensuring safe operations, and flange taps provide a reliable method for achieving this without interrupting the flow of the material.

Pharmaceutical industries utilize flange taps for the same reasons as chemical processes, allowing for clean and safe sampling of products. Moreover, in HVAC systems, flange taps play a significant role in monitoring temperature and pressure, helping to optimize system performance and energy efficiency.

flange taps

Advantages of Flange Taps

One of the primary advantages of using flange taps is their ability to provide convenient access to pipelines without disrupting the system. This minimizes downtime, allowing for quick inspections and maintenance activities.

Flange taps are also known for their durability and reliability. When properly installed, they can withstand high pressures and temperatures, making them suitable for a wide range of applications. Their robust connection methods ensure that they are leak-proof, contributing to the overall safety of the system.

In addition, flange taps are easy to install and can be customized to fit various piping configurations. Manufacturers offer a wide range of sizes and materials to meet specific requirements, allowing engineers and designers to select the optimal solution for each application.

Installation and Maintenance Considerations

Installing flange taps requires precision and adherence to specified standards. It is essential to ensure that the surfaces of both the flange and the tap are clean and free from debris to create a proper seal. Proper torque specifications for bolts should be followed to avoid over- or under-tightening, which can lead to leaks or flanges warping.

Once installed, regular maintenance of flange taps is vital. Routine inspections help identify any signs of wear or potential leaks early on, preventing costly downtime or damage to the system. If a tap becomes damaged or begins to leak, it’s typically advisable to replace it rather than attempt repairs, as this can ensure the integrity of the overall system.

Conclusion

Flange taps are essential components in modern piping systems across various industries. Their ability to facilitate easy access for monitoring and sampling makes them invaluable tools in maintaining operational efficiency and safety. Understanding their functionalities, applications, and maintenance requirements equips engineers and technicians with the knowledge needed to effectively implement flange taps in their systems. As industries continue to evolve, the importance of reliable and efficient fluid management tools like flange taps will only increase, driving innovation and safety in operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024