-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 04, 2024 10:05 Back to list

flange wnrf 150

Understanding Flange WNRF 150 A Comprehensive Overview

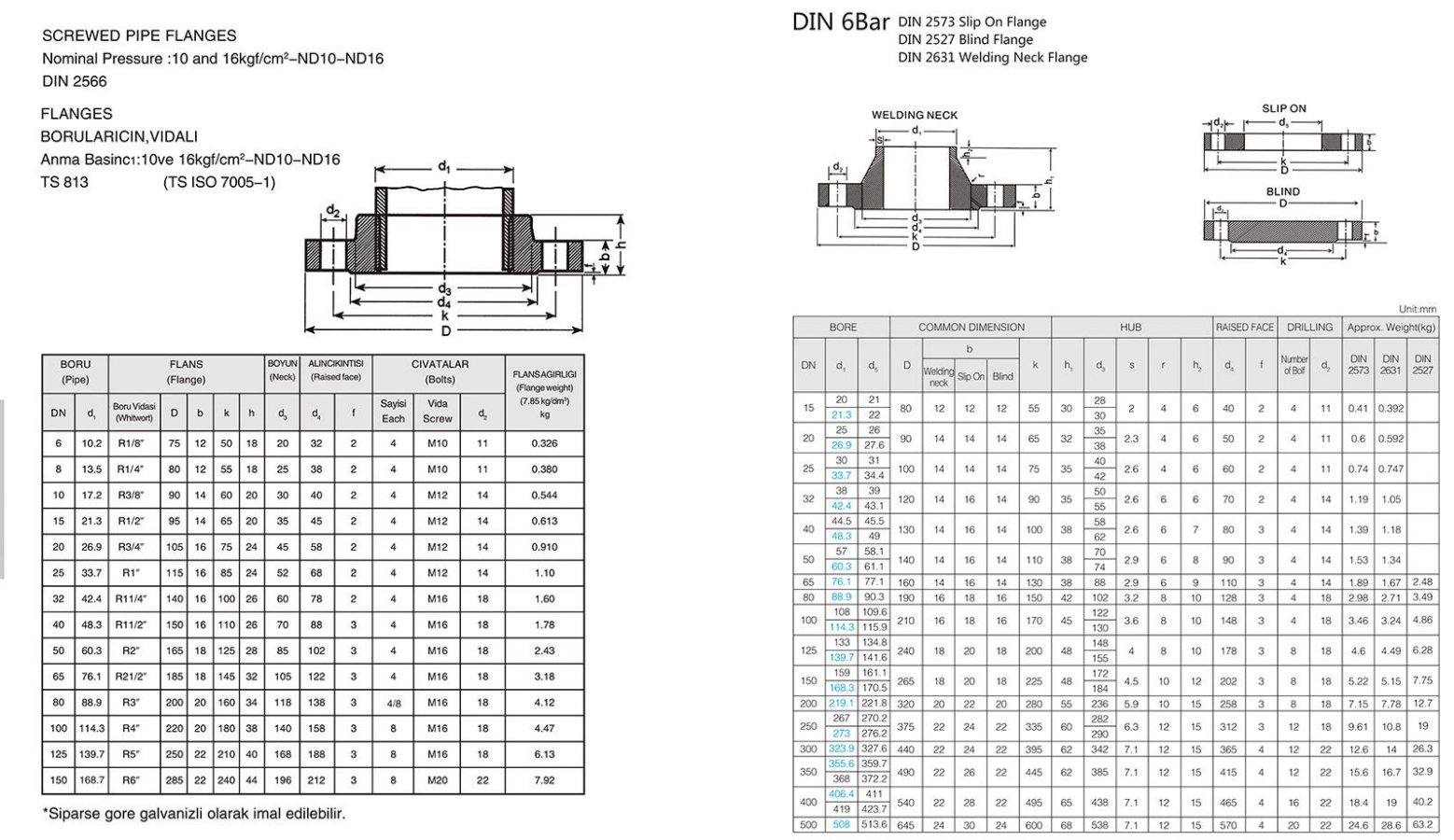

Flanges are an essential component in piping systems, serving as a method for connecting pipes, valves, pumps, and other equipment in various industrial applications. Among the different types of flanges available, the WNRF (Weld Neck Raised Face) 150 flange holds significant importance due to its design and functionality. This article delves into the features, applications, and advantages of the WNRF 150 flange.

What is a WNRF 150 Flange?

The WNRF flange is a specific type of welded flange that is primarily used in high-pressure piping systems. The number 150 refers to its pressure class, indicating that the flange is suitable for applications with a nominal pressure of 150 psi (pounds per square inch) at a specific temperature. The design of a WNRF flange includes a raised face which helps in creating a tighter seal when bolted to another flange or fitting.

Key Features

1. Design The WNRF flange has a long neck that extends from the base of the flange. This neck is welded to the pipe, providing stability and excellent support for the joint.

2. Material WNRF flanges are available in various materials, including carbon steel, stainless steel, and alloy steel. The choice of material depends on the specific application and the environment in which the flange will operate.

3. Pressure Ratings As already mentioned, the 150 designates the flange’s pressure class. This means it can handle certain pressure levels safely, making it suitable for many applications in industries such as oil and gas, chemical processing, and water treatment.

4. Versatility The WNRF 150 flange can be utilized in a wide range of pipe sizes and configurations, adding to its versatility across different industries.

Applications

flange wnrf 150

WNRF 150 flanges find extensive use in various applications, including

- Oil and Gas Industry Due to its ability to withstand high pressures, WNRF 150 flanges are widely used in pipelines transporting crude oil, natural gas, and refined products.

- Chemical Processing The chemical industry often employs these flanges in systems where the integrity of pressure vessels and pipes is critical to preventing leaks and ensuring safety.

- Water and Wastewater Management These flanges are also common in municipal water systems, where they connect different sections of pipelines.

Advantages

One of the primary benefits of using WNRF 150 flanges is their robustness and reliability. The welded neck design enhances the strength of the connection, making it less prone to leaks and failures. Additionally, the raised face provides an improved sealing surface, which is critical for maintaining the integrity of high-pressure systems.

Another advantage is that WNRF flanges are easy to install and maintain. Their design allows for straightforward alignment with bolts, facilitating quick assembly or disassembly when repairs or replacements are necessary.

Conclusion

In summary, the WNRF 150 flange plays a vital role in various piping systems across multiple industries. Its robust design, suitability for high-pressure applications, and versatility make it a preferred choice for engineers and designers. Whether used in oil and gas pipelines, chemical processing facilities, or municipal water systems, the WNRF 150 flange ensures safe and efficient operations. By understanding the features and applications of this essential component, industries can better equip themselves for the challenges posed by modern infrastructure needs.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024