-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 21, 2024 22:39 Back to list

forged fittings socket welding and threaded

Forged Fittings Socket Welding and Threaded Applications

In the world of piping systems, forged fittings play a critical role in ensuring the integrity and efficiency of fluid and gas transportation. Among the various types of fittings available, socket welding and threaded fittings are two popular methods used for joining pipes. Each of these techniques has its unique properties, advantages, and applications, making them suitable for different industries and situations.

Understanding Forged Fittings

Forged fittings are made from a solid piece of metal that is heated and shaped through a series of hammering or pressing processes, resulting in a product that is robust and durable. The forging process generally enhances the mechanical properties of the metal, providing excellent strength and resistance to pressure and temperature fluctuations. Common materials used for forged fittings include carbon steel, stainless steel, and alloy steel, each chosen based on the specific requirements of the application.

Socket Welding Fittings

Socket welding is a widely utilized method for joining pipes in pressure systems. In this technique, a pipe is inserted into a recess in the fitting, which is then welded around the joint. This method is often preferred for its ease of use and reliability, especially in applications involving high-pressure systems. Socket welding fittings are designed to provide a smooth and continuous flow of fluids, minimizing turbulence and pressure drops.

One significant advantage of socket welding fittings is their ability to withstand high pressure and temperature conditions, making them ideal for applications in the oil and gas, chemical, and power generation industries. Additionally, the welded joint creates a permanent bond that offers high resistance to leakage, which is critical in maintaining safety and efficiency in operations.

However, socket welding has its limitations. The requirement for welding equipment and skilled labor can increase installation costs and time. Furthermore, the nature of the process creates a heat-affected zone (HAZ), which may affect the material properties of the fittings and pipes if not managed correctly.

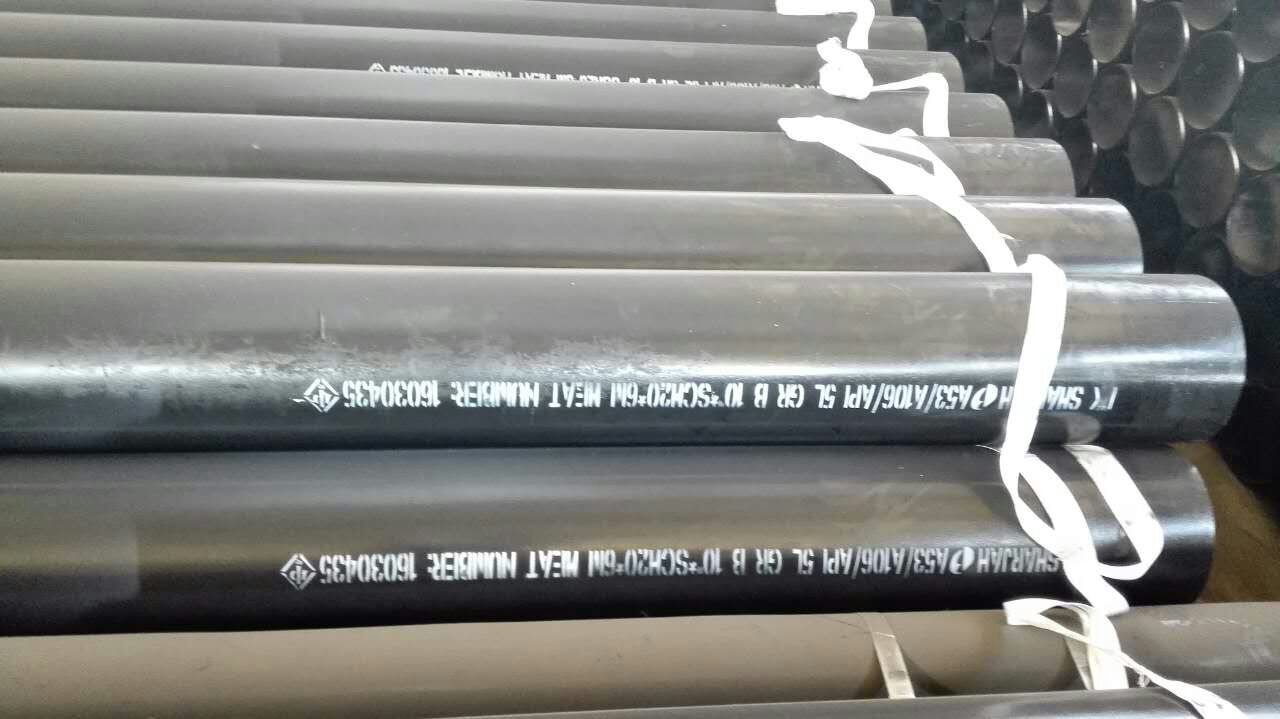

forged fittings socket welding and threaded

Threaded Fittings

In contrast, threaded fittings are joined through the use of screw threads. This method simplifies the assembly process, as it does not require welding equipment. Threaded fittings allow for easy disassembly and reassembly, making them a favorable choice for applications where flexibility and maintenance are essential.

Threaded fittings are commonly used in low-pressure applications, where the risk of leakage is minimal. They are suitable for various industries, including plumbing, HVAC (heating, ventilation, and air conditioning), and manufacturing. The quick installation process and the need for less specialized labor make threaded fittings a cost-effective solution.

However, while the simplicity of threaded fittings is an advantage, they also come with challenges. The potential for leaks increases with the presence of threads, and the fittings often cannot withstand the same high pressure and temperature conditions as socket welded fittings. Consequently, careful consideration must be given to the operating conditions when selecting threaded fittings.

Conclusion

When choosing between socket welding and threaded forged fittings, several factors should be considered, including the specific application requirements, pressure and temperature conditions, installation ease, and maintenance needs. Socket welding offers durability and strength for high-pressure applications, while threaded fittings provide flexibility and ease of installation for lower-pressure systems.

In summary, both socket welded and threaded forged fittings have their unique strengths that make them suitable for various scenarios in piping systems. Understanding these methods is crucial for engineers and technicians to ensure the reliability and safety of fluid handling systems across different industries. Selecting the right type of fitting not only enhances operational efficiency but also contributes to the overall integrity of the piping network.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024