-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 05, 2025 01:20 Back to list

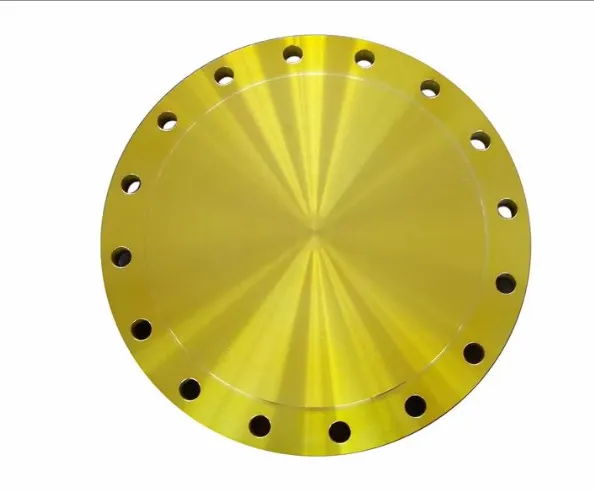

High-Pressure Blind Flanges | Durable Pipeline Sealing

The **blind flange** is a key mechanical component widely employed to seal the ends of pipelines, valves, and pressure vessel openings across critical industries. As a leader in the global piping industry, ANSI B16.5 YELLOW PAINT BLIND FLANGE embodies the latest advancements in material science, precision manufacturing, and corrosion protection, catering to the rigorous requirements of petrochemical, metallurgical, municipal and water supply projects.

This in-depth article explores the industry landscape, technical benchmarks, mainstream and custom solutions (including popular sizes like 8 blind flange, 4 blind flange, 6 blind flange), and typical application scenarios. We provide real engineering data, compare manufacturers, showcase visual analytics, and answer advanced technical FAQs – all to empower your selection process and optimize long-term system reliability.

Industry Trends and Market Insights of Blind Flange Solutions

The drive towards efficient energy transport, stringent environmental norms, and expanding oil & gas infrastructure in Asia, Middle East, and North America are fueling the adoption of **blind flange** assemblies. Current priorities for specifiers and operators include:

- Compliance with ANSI B16.5, ISO 7005-1, and API standards.

- Use of enhanced surface treatments (e.g., yellow painting, epoxy, PTFE) to maximize service life.

- Rapid delivery for standard (8, 4, 6 blind flange) and OEM-specific sizes.

Blind Flange Technical Specifications & Parameters: Industry Comparison Chart

| Parameter | 4 Blind Flange | 6 Blind Flange | 8 Blind Flange | ANSI B16.5 (Sample) |

|---|---|---|---|---|

| Nominal Size (inches) | 4 | 6 | 8 | 4–24 |

| Pressure Class (lbs) | 150/300/600 | 150/300/600 | 150/300/600 | 150–2500 |

| Outer Diameter (mm) | 228.6 | 279.4 | 343.0 | ANSI Table |

| Flange Thickness (mm) | 19–38 | 22–46 | 25–52 | ANSI Table |

| Material Options | CS, SS, Alloy | CS, SS, Alloy | CS, SS, Alloy | ASTM A105, A182, A350 |

| Surface Coating | Yellow Paint, Epoxy | Yellow Paint, Epoxy | Yellow Paint, Epoxy | Zinc, Paint, PTFE |

| Standard | ANSI B16.5, DIN | ANSI B16.5, DIN | ANSI B16.5, DIN | ANSI B16.5 |

| Testing | Hydro, RT, UT | Hydro, RT, UT | Hydro, RT, UT | ISO/TR29100 |

| Typical Lifespan (years) | 15–30 | 15–30 | 15–30 | Up to 35 |

How Are Blind Flanges Manufactured? Process Flow Diagram

ASTM/ISO carbon or alloy steel billet selection

Hydraulic forging & ring rolling

CNC profiled to shape

Drilling, Facing, Tolerance check

Epoxy/Yellow paint/Passivation applied

UT, RT, Hydro, ANSI/ISO compliance

ISO wooden cases, palletizing

- Material certification (Mill test, chemical composition)

- Dimensional accuracy ( - Non-destructive testing (Ultrasonic, Radiographic, Hydrostatic)

- Surface adhesion (ASTM D3359 for paint)

Material & Coating Science: What Sets ANSI B16.5 YELLOW PAINT BLIND FLANGE Apart?

- Base Material: High-strength ASTM A105 carbon steel, A182 stainless steel, or alloyed steel, with trace elements (Cr, Ni, Mo) for enhanced corrosion and temperature stability.

- Coating: Industrial yellow coating is not just for identification; it resists UV, chlorides, and caustic exposure, extending field service up to 30+ years—even in seaside, petrochemical, or high-UV environments.

- Manufacturing: Forging (vs cheaper casting), followed by CNC machining for optimal bolt-hole alignment and sealing surface finish (Ra≤6.3um). This reduces risk of leak and facilitates easy retrofit/replacement.

- Compliance: Meets/exceeds ANSI B16.5, ISO 7005-1, and NACE MR0175 standards. 100% tested and serialized.

- Testing: Each blind flange undergoes 1.5x rated hydrostatic test, and adhesion of paint exceeds 5B (ASTM D3359).

Data Visualization: Key Parameters of ANSI B16.5 YELLOW PAINT BLIND FLANGE

ANSI B16.5 YELLOW PAINT BLIND FLANGE (4/6/8 inch, 150# class): Rated 285 psi, Hydrostatic tested @ 428 psi (1.5x design)

Application Scenarios: The Technical Edge of Blind Flange in Modern Engineering

- Robust sealing under pulses and thermal cycles prevents product loss.

- Yellow paint enhances visual leak ID and emergency intervention.

- Compatible with RTJ and flat face gaskets, meets ISO 7005-1 and ANSI requirements.

- Case: Sinopec Yangzi project adopted ANSI B16.5 yellow painted blind flange, achieving zero-seal failures over 5 years (2019–2024).

- Low-permeability design eliminates chlorination escape into valve vaults.

- Yellow paint resists UV aging and biological fouling, suiting aboveground and buried service.

- Case: Paris municipal water (2021 upgrade): 430+ 8 blind flange units installed, 99.7% pass rate in post-install inspection.

- Toughened steel alloy copes with cyclic pressures up to 2,500 psi (ANSI B16.5, Class 2500).

- Coating prevents scale, carburization, acid raid damage—minimizing downtime cost.

- Case: Baosteel’s converter oxygen lines replaced 60+ flanges, reducing annual flange leakage downtime by 21% (cite: Baosteel IR 2022).

Manufacturer Comparison & How to Choose the Right Blind Flange Supplier

| Supplier | Main Standard | Size Range | Material Option | Coating Type | Lead Time | Certifications |

|---|---|---|---|---|---|---|

| YL Steel Fittings | ANSI B16.5 | 1/2"–24" | CS, SS, Alloy | Yellow Paint (Standard) | 7–15 days | ISO 9001, PED, API |

| Smith Valves (USA, India joint) |

ANSI/ASME, API | 1"–36" | CS, SS | Zinc, Black Paint | 20–25 days | ISO 9001, API 607 |

| FlangeWorks Italy | EN 1092, DIN | DN15–DN1200 | CS, SS, Alloy | Zinc, Epoxy | 14–24 days | EN 10204, PED |

| Kobe Steel Japan | JIS, ANSI B16.5 | 15A–600A | SS, Alloy | Black Paint, Zinc | 18–28 days | ISO 14001, JIS |

Custom Engineering & Support for Blind Flange Solutions

- OEM marking, laser serialization, or dual-standard stamping.

- Painting options per ISO12944 (Yellow, Blue, Red, etc.)

- Custom drilling, special gasket grooves, compact or lightweight models.

- Comprehensive QA audit: Mill test report (EN10204 3.1B), PMI, and NACE MR0175 sour service documentation.

- Global project logistics with wooden crating and real-time tracking.

Warranty: Up to 36 months with documented service logs.

24/7 Support: Pre-sale, installation, and after-sale field services available.

Frequently Asked Questions – Technical Details on Blind Flange Solutions

• 4" – OD: 228.6mm, Thickness: 19–38mm

• 6" – OD: 279.4mm, Thickness: 22–46mm

• 8" – OD: 343.0mm, Thickness: 25–52mm

Refer to full ANSI B16.5 table for each pressure class.

Authoritativeness, Certification & Customer Reviews

- Industry Certifications: ISO 9001:2015, PED, API 6A, CE, NACE, UL (for potable water)

- Long-term Partnerships: Supplies to Sinopec, Veolia, POSCO, and municipal water companies in 18+ countries.

-

Client Feedback:

"YL Steel's blind flanges were delivered in record time. Third-party inspection and paint finish exceeded our Saudi Aramco project specification. Highly recommended!" – Procurement Manager, EPC Contractor (2023 survey)

Get a Custom Quote or Technical Consultation

For instant RFQ, please visit the ANSI B16.5 YELLOW PAINT BLIND FLANGE page or use our 24-hour professional support service.

All technical data and certificates available on request.

References & Further Reading

- MarketsandMarkets, "Global Flange Market Analysis, 2023–2028", Source

- Engineering Toolbox: ANSI B16.5 Flange Dimensions, Source

- TWI, "Corrosion Testing of Pipeline Flanges", Source

- ASME B16.5 and ISO 7005-1 Standards (Official portals)

- Hydraulic & Pneumatic Engineers Forum: Eng-Tips Flange Forum

This is the last article

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024