-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Apr . 29, 2025 13:34 Back to list

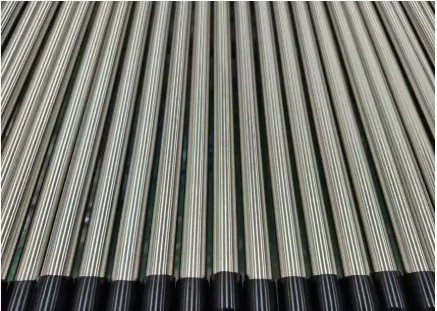

High-Pressure Rated Seamless Stainless Steel Pipe: Engineered to Meet API/ASME Standards for Critical Systems

In the demanding world of industrial infrastructure, where safety and reliability are non-negotiable, seamless stainless steel pipe emerges as a cornerstone for high-pressure systems. YULONG Steel, a trusted name among stainless steel pipe fittings suppliers, has perfected the art of manufacturing these critical components to meet the rigorous API and ASME standards, ensuring optimal performance in the most challenging environments. Whether you require the corrosion resistance of 316L stainless steel pipe or the versatility of 304L stainless steel pipe, YULONG Steel delivers solutions that blend engineering precision with uncompromising quality.

The Essence of API/ASME Compliance in Seamless Stainless Steel Pipe

The API (American Petroleum Institute) and ASME (American Society of Mechanical Engineers) standards are globally recognized benchmarks for materials used in high-pressure applications. YULONG Steel’s seamless stainless steel pipe is meticulously engineered to adhere to these standards, guaranteeing uniform wall thickness, precise dimensional accuracy, and superior mechanical properties. For industries like oil and gas, chemical processing, and power generation, where system failures could have catastrophic consequences, this compliance is not just a feature but a necessity.

YULONG Steel Seamless Stainless Steel Pipe: Key Advantages of API/ASME Rated Pipes

Unmatched Pressure Resistance: These pipes are designed to withstand up to 2,500 PSI, ensuring leak-proof performance in high-pressure pipelines transporting hydrocarbons, steam, or corrosive fluids.

Thermal Stability: Maintaining structural integrity across a wide temperature range (-200°C to 600°C), they excel in extreme environments such as refinery crackers or cryogenic storage facilities.

Stringent Quality Control: Every pipe undergoes non-destructive testing (NDT), including ultrasonic and radiographic inspection, to eliminate even micro-level defects.

Material Excellence: Choosing Between 304L and 316L Stainless Steel Pipe

YULONG Steel offers two primary grades of seamless stainless steel pipe, each tailored to specific industrial needs:

304L Stainless Steel Pipe: The Versatile Workhorse

Ideal for general corrosion resistance, 304L (a low-carbon variant of 304) features excellent ductility and formability. It performs exceptionally in environments with mild chemical exposure, such as:

Water treatment plants, where it resists chloride-induced pitting.

Food and beverage processing, thanks to its non-reactive surface, and compliance with hygiene standards.

HVAC systems, where their thermal conductivity ensures efficient heat transfer.

316L Stainless Steel Pipe: Mastering Harsh Conditions

For applications demanding superior resistance to aggressive chemicals and seawater, 316L (with added molybdenum) is the go-to choice:

Offshore oil platforms, which defy saltwater corrosion and high-pressure subsea flows.

Chemical reactors handling sulfuric acid or chloride-based solutions.

Pharmaceutical facilities require compliance with USP Class VI standards for purity.

YULONG Steel: Redefining Reliability as a Stainless Steel Pipe Fittings Supplier

As a leading stainless steel pipe fittings supplier, YULONG Steel combines technical expertise with customer-centric innovation:

1. Custom Solutions for Complex Requirements

Whether you need non-standard diameters (ranging from 6mm to 1,200mm OD) or special lengths up to 12 meters, their state-of-the-art mills and rolling equipment deliver precision-tailored pipes. Projects requiring exotic alloys or custom heat treatments benefit from their in-house metallurgy lab, ensuring material properties align with exact specifications.

2. Global Compliance, Local Service

With certifications including API 5L, ASME SA312, and CE/PED, YULONG Steel’s pipes integrate seamlessly into international projects. Their logistics network ensures timely delivery to over 50 countries, supporting everything from large-scale LNG terminals to boutique chemical plants.

3. Cost-Effective Quality

By optimizing production processes and maintaining a 50,000-ton inventory of raw materials, YULONG Steel offers competitive pricing without compromising on quality. This makes them the preferred partner for businesses looking to buy stainless steel pipe that balances performance and value.

Applications: Where High-Pressure Seamless Stainless Steel Pipe Shines

Oil & Gas: Connecting subsea wells to topside processing units, where 316L stainless steel pipe withstands hydrogen sulfide (H2S) and high-pressure hydrocarbon flows.

Power Generation: Transporting superheated steam in thermal power plants, with 304L stainless steel pipe ensuring long-term resistance to oxidation and creep.

Marine Engineering: Fabricating ballast water systems and offshore pipelines, where corrosion resistance is non-negotiable.

When you buy stainless steel pipe from YULONG Steel, you’re not just purchasing a product—you’re investing in peace of mind. Their seamless stainless steel pipe, engineered to API/ASME standards and available in grades like 304L and 316L, offers the reliability that critical systems demand. As a trusted stainless steel pipe fittings supplier, they stand behind every meter of pipe with technical support, rapid delivery, and a commitment to exceeding expectations.

Contact YULONG Steel today to discover how their high-pressure rated pipes can elevate the safety and efficiency of your industrial projects.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024