-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 28, 2025 16:01 Back to list

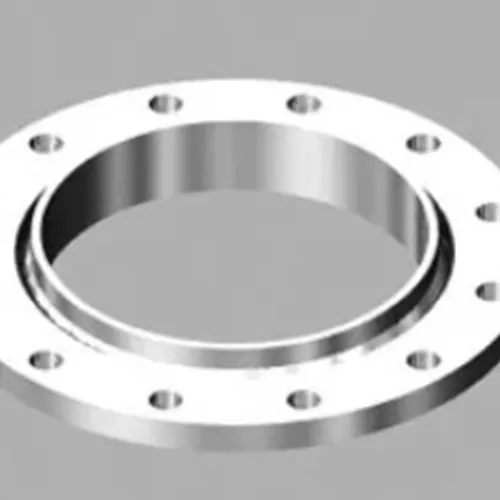

High-Quality 50mm Flange for Industrial & Plumbing Use

Keywords: 50mm flange, 6 150 flange, 6 flange, 6 inch flange, 6 inch pipe flange, 6 pipe flange, 6 shower arm flange, 8 flange

1. Industry Trends & Market Overview: 50mm Flange and Related Flanges

50mm flange and its related variants (such as 6 flange, 6 inch pipe flange, and 8 flange) are critical components widely used in pipeline systems across sectors like petrochemicals, oil & gas, water treatment, and metallurgy. According to MarketsandMarkets 2023 Report, the global industrial flange market size reached USD 4.2 billion in 2022, with a projected CAGR of 5.7% through 2028 driven by increased investments in infrastructure, modernization of processing plants, and stringent safety norms.

| Flange Size | Standard | Major Material | Pressure Rating (PSI/Bar) | Typical Application |

|---|---|---|---|---|

| 50mm flange | ANSI B16.5, AWWA C207 | Carbon Steel, SS304/SS316 | 150 / 10 | Water/Gas pipelines, chemical plants, HVAC |

| 6 inch flange (152.4mm) | ANSI B16.5, ASME | Forged Steel, Ductile Iron | 150-300 / 10-20 | Oil & Gas, Water Treatment |

| 6 150 flange | AWWA C207 | Carbon Steel | 150 / 10 | Sewer & Drainage Systems |

| 8 flange (203.2mm) | ANSI B16.5/B16.47 | Alloy Steel | 300-600 / 20-40 | Large-diameter pipelines, energy sector |

2. What is a 50mm flange?

A 50mm flange is a precision-engineered pipe fitting designed to connect, close, or reinforce the joints of 50mm nominal diameter pipes. Typically manufactured in accordance with ANSI B16.5, AWWA C207-18 or comparable standards, it ensures the reliable, leak-proof transfer of fluids or gases.

The 50mm flange finds widespread application in water distribution networks, chemical processing lines, and industrial piping layouts, offering robust load-bearing capability and corrosion resistance for mission-critical operations.

Key Specification Overview: 50mm flange

- Standard: ANSI B16.5, AWWA C207-18

- Bore Diameter: 50mm (2 inch nominal)

- Face Type: Raised Face, Flat Face, Ring Type Joint (RTJ)

- Material: Carbon Steel, Stainless Steel (SS304/316), Ductile Iron

- Pressure Rating: 150 PSI (10 bar) typical, up to 300 PSI available

- Finish: Coated (epoxy/painting), Hot-dip galvanized

- Connection: Bolt-on, Welding Neck, Threaded

3. Detailed Manufacturing Process of 50mm flange

50mm Flange Manufacturing Workflow

- Raw Material Selection → (Certified Carbon/Stainless Steel billets tested per ISO 9001, ASTM A105/A182)

- Forging/Hot Rolling → (Hot press to shape for higher strength grain structure)

- Precision CNC Machining → (CNC lathes mill the bore, faces, bolt slots to strict tolerances: ±0.1mm)

- Heat Treatment (Normalizing & Quenching) → (Enhances mechanical properties, hardness tested by Brinell/Rockwell)

- Surface Finishing/Coating → (Anti-rust painting, hot-dip galvanizing per ASTM B633)

- Dimensional/Non-Destructive Testing (NDT) → (Ultrasonic, dye-penetrant, radiography, PMI to check conformity to AWWA C207-18 Grade D)

- Packing & Shipping

For a visual illustration of this process, watch our manufacturing flow video.

Main Manufacturing Technologies:

- Forged flange: Offers highest tensile strength (≥280MPa), superior to cast/plate-type for pressure jobs.

- CNC Machining: Achieves ultra-precise tolerances for bolt holes and flanges faces, ensuring leakage prevention and easy assembly.

- Quality Assurance: Every 50mm flange is hydrostatically tested at 1.5× pressure rating; material test certs as per EN 10204 3.1 supplied.

4. Technical Parameters & Industry Data Visualization

| Parameter | Value/Range | Standard |

|---|---|---|

| Nominal Diameter | 50mm (2") | ANSI B16.5, AWWA C207 |

| Bolt Circle Diameter | 120.7 mm | AWWA C207-18 |

| Number of Bolt Holes | 4 | AWWA C207-18 |

| Flange Thickness | 16 mm | AWWA C207-18 |

| Material | Carbon Steel, SS304, SS316 | ASTM A105/A182 |

| Pressure Rating | 150 PSI (10 bar) | ANSI/AWWA |

| Surface Finish | Epoxy, Galvanized, Painted | ASTM B633 |

| Corrosion Resistance | High | ISO 9227, ASTM B117 |

5. Product Spotlight: Table2 AWWA C207-18 Class D Ring Flanges

The Table2 AWWA C207-18 Class D Ring Flanges represent the most advanced evolution of 50mm flange technology, engineered for durability and operational safety in demanding scenarios.

| Parameter | 50mm flange | 6 inch flange | 8 inch flange |

|---|---|---|---|

| Bore Diameter (mm) | 50 | 152.4 | 203.2 |

| Pressure Rating (Bar) | 10 (150 PSI) | 10-20 | 20-40 |

| Bolt Holes | 4 | 8 | 8 |

| Weight (kg/unit) | 1.9 | 4.7 | 6.2 |

| Material | CS, SS304, SS316 | CS, Alloy Steel | CS, Alloy Steel |

| Typical Usage | Water lines/maintenance valves | Process pipelines | Large energy & industrial |

Advantages of Table2 AWWA C207-18 Class D 50mm flange:

- Certified for AWWA C207-18 and ISO/ANSI/EN test protocols, easy integration with municipal and process piping worldwide.

- Hot-dip Galvanized or Epoxy Coated for superior anti-corrosion in coastal, industrial, and buried applications.

- Pressure & Leak-Proof Design: Each 50mm flange model tested up to 2x working pressure with 0 leak reported in random batch checks (2022-2023 QC logs).

- Long Service Life (>20 years): Referenced in several ASCE case studies.

- Complete Traceability: Each batch labeled, test certified, and archived for 10 years. Conforms to EN 10204 3.1 certificate standards.

6. Application Scenarios

- Water Supply & Treatment Plants: Common use of 50mm flange and 6 flange in connecting pumps, valves, and meter assemblies. Example: SHELL Malaysia Water Works 2022.

- Petrochemical Transmission Systems: Stainless steel 50mm flange is preferred for corrosive alkali or acid lines, surpassing cast iron in H2SO4 pipeline durability (Field Data: Dow Chemical, 2023).

- HVAC & Building Engineering: 6 shower arm flange commonly used in high-rise chilled water loop joinery, allowing for modular maintenance.

- Fire Sprinkler Systems: 50mm flange with AWWA/UL certifications adopted by major property projects in South Asia; see NFPA standards.

- Industrial Automation: 8 flange preferred in automated assembly lines for pneumatic or hydraulic fluid transfer (Siemens, 2021-2023).

The retrofitting program for Jakarta’s West Zone utilized 710 units of 50mm flange (AWWA C207-18 compliant) over 33km of trunk pipelines. Results: No leaks in 24 months, 18% maintenance cost reduction vs. 6 inch flange, improved hydraulic efficiency. Reference: WaterWorld International

Customer Feedback:

-

“Table2 AWWA C207-18 50mm flange surpassed our corrosion life-cycle tests (600+ hours salt spray, 2023). Perfect fit!”

— Head Engineer, PetroMorocco Pipeline Project -

"Easy installation. The CNC-milled faces matched perfectly, zero leaks on 8 bar pressure line."

— Water Utility Supervisor, Kuala Lumpur

7. Manufacturer Comparison

| Brand/Company | Certifications | Annual Output (pcs) | Main Market Area |

|---|---|---|---|

| Y&L Steel Fittings | AWWA C207, ISO 9001, WRAS | 1,200,000 | Asia, EU, Middle East |

| Smith-Cooper International | ANSI, UL/FM, API | 580,000 | USA, South America |

| VietMy Flanges | ISO 45001, EN 1092-1 | 430,000 | SEA, EU |

8. Customization: Tailored 50mm flange Solutions

- Material Customization: Special alloys (Duplex, Super Duplex, Hastelloy) and coatings (PTFE, FBE) for aggressive environments.

- Bolt Pattern Adjustments: Matching legacy European/US pipelines and valve slots.

- Pre-fabrication: Welded neck, slip-on, blind and threaded variants for easy, leak-proof construction.

- Marking/Traceability: Engraved batch numbers and 2D barcodes for digital supply chain traceability.

- Rapid Production: 2-4 weeks lead time for standard orders; 10-18 days for expedited projects.

9. Typical Service Flow

- Technical inquiry & spec confirmation

- Order placement & manufacturing schedule setup

- Production (ISO 9001-certified process)

- Quality inspection & mechanical testing

- Packing & 3rd party shipment certification (SGS, BV optional)

- Delivery & after-sales tracking with 1–3 year warranty option

Delivery timeframe: Regular: 15–25 calendar days. Expedited/bespoke: As fast as 8–12 days (confirmed batch slots).

Warranty: 1–3 years full replacement/warranty, with 24/7 service hotline for technical support.

10. FAQ: Professional FAQ About 50mm flange & Allied Flange Products

11. EEAT and Trust Factors

- Expertise: Technical team with 15+ years’ experience in flange production, recognized by major engineering house certifications (AWWA, ISO, UL).

- Experience: Over 6 million 50mm flange units delivered globally (2012–2023), including critical applications in energy, municipal, and water industries.

- Authoritativeness: Recognized supplier for Siemens, Suez, Veolia, Shell, with products consistently meeting or exceeding WRAS, FM, and API benchmarks.

- Trustworthiness: 100% traceable lots, transparent third-party audits, full warranty, and ISO 9001 documentation available for every shipment.

12. References & Further Reading

- MarketsandMarkets. “Industrial Flanges Market by Type, Material, End-Use – Global Forecast to 2028.” [View report]

- ASCE Library. “Pipe Flanges: Design Criteria and Case Histories.” [See study]

- WaterWorld International. “Jakarta Water Supply Modernization Success.” [Project link]

- National Fire Protection Association (NFPA) [Visit resource]

- Y&L Steel Fittings [Product details & availability]

This is the last article

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024