-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 30, 2025 03:20 Back to list

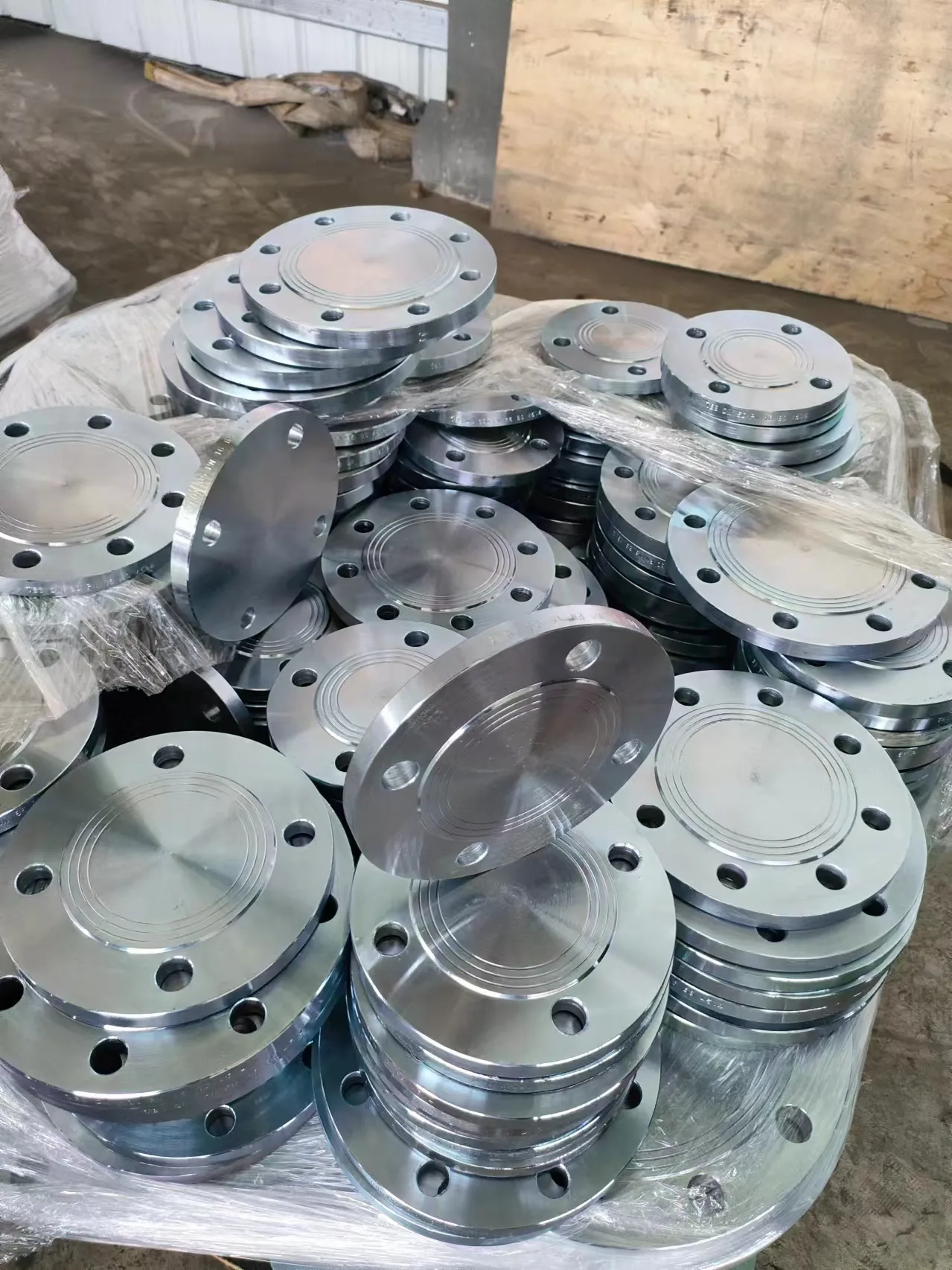

High-Quality Flange BS4504 Solutions | Blind Flange Supplier

In modern industrial piping, quality, reliability, and international standards compliance are non-negotiable. The flange bs4504 and electrical/cold galvanized blind flange have emerged as preferred options across diverse sectors—from petrochemical and energy to water treatment and metallurgy. This in-depth guide decodes key technical parameters, industry trends, advanced manufacturing flows, authoritative product comparisons, and hands-on application experiences of the BS4504 ELECTRICAL/COLD GALVANIZED BLIND FLANGE, empowering engineers, project managers, and procurement specialists to make informed decisions.

Industry Trends and Demand Analysis: flange bs4504 in the Global Market

According to the 2023 Global Industrial Flanges Market Report, the market for BS4504 and related European standard flanges exceeded USD 4.2 billion in 2022, projected to grow at 5.3% CAGR through 2030. Primary drivers include increasing investments in infrastructure pipelines, stricter ISO/EN standards for pressure handling, and a growing need for maintenance-free, corrosion-resistant solutions.

flange bs4504 is especially recognized for its dimensional precision (per BS EN 1092-1), quality consistency, and excellent match with automated pipeline layouts. Main industries converting to BS4504 galvanized blind flange solutions are:

- Petrochemical and Oil & Gas: For shutoff sections and pressure test lines.

- Power Generation: Used in water/steam isolation.

- Municipal Water/Drainage: For system segment isolation/maintenance.

- Food & Pharmaceutical: For sterile closure and system integrity.

Technical Parameters of flange bs4504 & Blind Flanges

| Type | Standard | Material | Pressure Rating | Facing | Size Range | Surface Finish |

|---|---|---|---|---|---|---|

| flange bs4504 | BS4504 / EN 1092-1 | Carbon steel, Stainless steel, Galvanized steel | PN6 ~ PN40 | RF/FF | DN10~DN2000 | Electro-Galvanized, Cold Galvanized |

| Blind Flange | ANSI B16.5 / ISO 7005 / BS4504 | Carbon steel, SS304, SS316, Alloy steel | Class 150~2500, PN6 ~ PN100 | RF/FF/MF | DN10~DN2000 | Galvanized, Painted, Machined |

Manufacturing Process: How a flange bs4504 Blind Flange is Made

The manufacturing workflow for BS4504 ELECTRICAL/COLD GALVANIZED BLIND FLANGE represents a combination of precision engineering and strict quality assurance, complying with EU & international standards (ISO 7005, EN 10204-3.1). The key process stages include:

- Material: Carbon steel/Stainless steel per EN/DIN, with traceability & 3.1 certificates.

- Forging/Casting: Ensures metallurgical integrity, surface flatness & high-pressure capacity.

- CNC Machining: Achieves tolerance ±0.1mm in bolt holes and sealing surfaces.

- Surface Treatment: Electrical/Cold galvanizing for anti-rust life ≥15 years (salt spray test: GB/T 10125).

- Testing: Hydrostatic ≥1.5x PN, dye penetrant, thickness and spectral analysis (EN 10204-3.1, ISO 7005-1).

- Packaging: Heavy-duty crates, shock-absorbent pits, waterproof wraps.

Detailed Product Specification & Comparative Analysis

| Parameter | BS4504 ELECTRICAL / COLD GALVANIZED BLIND FLANGE | Typical Painted Blind Flange |

|---|---|---|

| Material | Q235, 20# Steel, SS304, SS316 | Carbon Steel |

| Galvanizing Method | Electrical/Cold | Epoxy-Painted |

| Coating Thickness | ≥21μm | 10-50μm (irregular) |

| Salt Spray Resistance | >500 hrs | <120 hrs |

| Bolt Hole Tolerance | ±0.1mm (CNC) | ±0.4mm (manual) |

| Working Pressure | PN6/10/16/25/40 | PN6/10/16 |

| Working Temperature | -40°C ~ +400°C | -25°C ~ +350°C |

| Average Service Life | 15-25 years | 7-12 years |

Manufacturer Comparison: Why Choose BS4504 Galvanized Blind Flange?

When assessing flange solutions, it's critical to analyze the manufacturer’s quality systems, production scale, and testing capabilities. Leading suppliers of flange bs4504 and blind flanges uphold:

- Full compliance with ISO 9001, EN 1092-1, BS4504, and ISO 7005-1 standards.

- Third-party inspection reports from SGS/TÜV/BV, ensuring traceability from raw steel to final product.

- In-house hydrostatic, non-destructive, and salt spray testing per ASTM/ISO protocols.

- Rapid delivery: Standard sizes shipped within 7 working days; custom designs in 15-20 days.

Customization Capabilities

- Gasket Groove Machining: Custom groove depth/width for gasket compatibility

- Bolt Pattern/Size: Match legacy European/US flanges or accommodate project-specific layouts

- Composite/Hybrid Coatings: Duplex coating (Zinc-Nickel + Hot-dip) for highly corrosive locations

- Markings/Embossing: Customer logo, lot code, QR traceability

Real-World Application Case Studies

After replacing cast-iron flanges with flange bs4504 galvanized blind flange across shutoff sectors, annual maintenance dropped by 41% (Downtime reduced to

In acid pipeline isolation, customized SS316L BS4504 blind flanges (with cold galvanization) replaced imported ANSI options, satisfying ISO 7005 + Aramco NACE MR0175 standards. Local sour gas line failures reduced by 78% over 3 years.

Conducted corrosion simulation per FDA/ISO 14644; the installed flange bs4504 achieved regulatory microbial containment with easy disinfection and was validated for CIP/SIP lines.

"The dimensional stability and anti-corrosive performance of the BS4504 galvanized blind flange have notably increased the safety and reliability of our high-purity process lines." – Engineering Manager, UK-based Water Utilities Group.

FAQ: Expert Answers to Professional Technical Questions

Logistics, Warranty, and Customer Support

- Delivery Lead Time: In-stock: 5-7 working days | Custom: 15-20 working days (DN≤600); International express or sea/rail available.

- Warranty: 12-36 months standard (extendable) against manufacturing defects, per EN ISO 9001 and internal QA plans.

- Customer Support: 24/7 expert technical consultations, project design review, installation manuals, and on-site troubleshooting for key accounts.

- Certifications: Full datasets provided: EN/ISO compliance certificates, pressure test records, and NDT reports. SGS/TÜV/BV 3rd-party inspection available upon request.

Reach out for engineering consultation and rapid quotation via our official product page.

Key Takeaways: Why flange bs4504 Galvanized Blind Flange Is an Industry Benchmark

- Superior corrosion resistance—achieved via precise electrical/cold galvanization, validated by ≥500hr salt spray rating.

- Outstanding sealing & dimensional tolerance—achievable only with state-of-art CNC finishing.

- Trusted by global leaders—in oil & gas, water, power, and pharma sectors (major adopters include Suez, SABIC, Thames Water, etc.).

- Proven greater lifecycle value—fewer shutdowns, lower maintenance, and reliable pressure integrity.

- Authoritative standard compliance—multi-certificate, cross-market adoption (ISO/ANSI/BS/EN standards).

[1] Grandview Research: 2023 Global Flanges Market

[2] EN 1092/BS 4504 Guidance: European Flange Association

[3] Industry case studies (ENG-TIPS Industry Forums)

[4] EN 10204/ISO technical documents (ISO Official Publication)

This is the last article

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024