-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 07, 2024 03:42 Back to list

hydraulic flange

Understanding Hydraulic Flanges Key Components in Fluid Power Systems

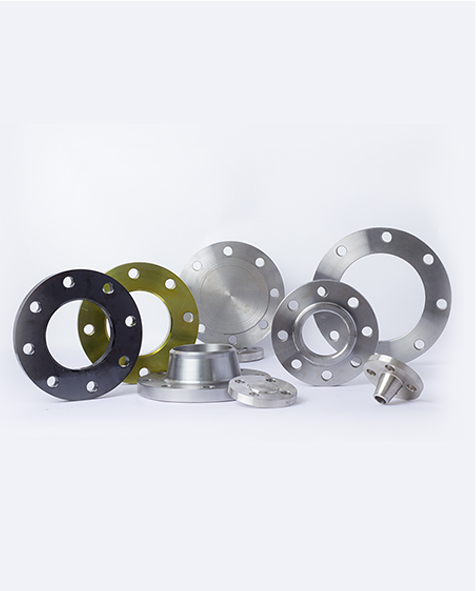

Hydraulic flanges are critical components in fluid power systems, playing a vital role in connecting different parts of machinery and ensuring the effective transfer of hydraulic fluids. These flanges are used in various applications, ranging from industrial machinery and construction equipment to aerospace systems and automotive design. Understanding the importance, types, and installation of hydraulic flanges can greatly enhance the efficiency and safety of hydraulic systems.

At its core, a hydraulic flange is a flat piece of material—usually metal—that forms a connection between two hydraulic components. They typically come in pairs, each having a raised edge known as a lip that helps to create a seal when clamped together with bolts. The main purpose of hydraulic flanges is to provide a leak-proof connection that can withstand the high pressures commonly found in hydraulic systems.

One of the key advantages of hydraulic flanges lies in their ability to handle high-pressure applications

. Unlike threaded connections, which can be prone to loosening or damage under stress, flanged connections can provide a more secure and stable joint. This results in fewer leaks and reduced maintenance needs, making flanges a popular choice in industrial environments.hydraulic flange

Hydraulic flanges come in various shapes, sizes, and pressure ratings, tailored to meet the specifications of different applications. The most common types include flat-face flanges, raised-face flanges, and blind flanges. Flat-face flanges are typically used in low-pressure systems and offer a larger sealing surface for improved reliability. Raised-face flanges, on the other hand, are ideal for high-pressure applications as they provide a concentrated sealing surface that increases performance under stress. Blind flanges are designed to close off the end of a piping system, providing a secure seal when a pipe or fitting does not require an outlet.

Selection of the appropriate hydraulic flange requires careful consideration of several factors. The material of the flange is crucial; common materials include carbon steel, stainless steel, and aluminum, each offering different advantages in terms of strength, corrosion resistance, and weight. The size and pressure rating of the flange also need to match the system requirements to ensure optimal performance. Furthermore, compatibility with the hydraulic fluid being used is essential to prevent chemical reactions that might degrade the materials.

Installation of hydraulic flanges is a delicate process that demands attention to detail. Proper surface preparation is key; the mating surfaces must be clean and free from debris. Once aligned, the flanges should be bolted together in a criss-cross pattern to ensure an even distribution of pressure. Over-tightening can lead to flange damage or warping, while under-tightening can result in leaks. Therefore, adhering to the manufacturer's specifications for torque settings is imperative.

In conclusion, hydraulic flanges are indispensable components in modern hydraulic systems, providing strong, reliable connections that can handle high-pressure environments. Their versatility and efficiency make them suitable for a wide variety of applications across numerous industries. Understanding the types, materials, and installation processes of hydraulic flanges is essential for engineers, technicians, and operators who aim to optimize the safety and performance of fluid power systems. By ensuring proper selection and installation, users can enjoy the benefits of these essential components, reducing maintenance needs and enhancing overall system reliability.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024