-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 25, 2024 16:38 Back to list

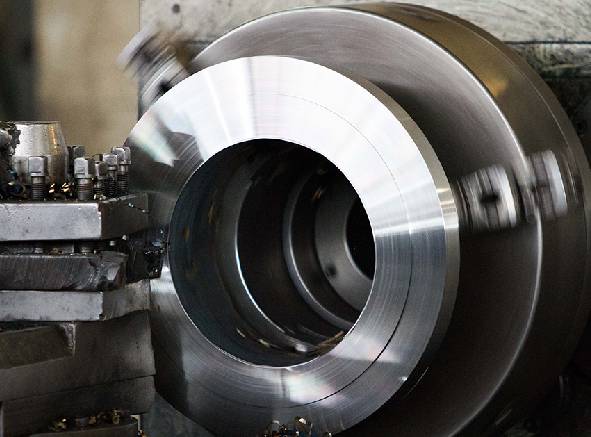

hydraulic pipe welding

Hydraulic Pipe Welding Techniques, Applications, and Best Practices

Hydraulic systems are crucial in various industries, from construction and manufacturing to automotive and aerospace. These systems rely on hydraulic pipes to transport fluid under pressure, essential for powering machinery, lifting equipment, and enabling complex operations. The integrity of hydraulic pipes is paramount, as any failure could lead to catastrophic consequences. Therefore, welding these pipes is a task that must be carried out with precision and expertise.

Importance of Hydraulic Pipe Welding

Welding hydraulic pipes forms a critical connection that must withstand high pressures and harsh working conditions. Properly welded joints ensure that the fluid remains contained within the system, maintaining operational efficiency and safety. Leaks can result not only in performance degradation but also pose risks to personnel and the environment.

Common Welding Techniques

Several welding techniques are commonly used in hydraulic pipe welding, including

1. TIG Welding (Tungsten Inert Gas Welding) This process is known for its precision and produces high-quality welds. It is ideal for welding thin materials and is often used for stainless steel pipes that are prevalent in hydraulic systems due to their corrosion resistance.

2. MIG Welding (Metal Inert Gas Welding) Easier to automate than TIG welding, MIG welding is often used for thicker materials. It provides a good balance between speed and quality, making it suitable for hydraulic pipe fabrication where speed is essential without compromising weld integrity.

3. Stick Welding (SMAW) This method is less common for hydraulic pipes due to its limitations with thin materials but can still be utilized in certain applications, especially where accessibility is a concern.

4. Submerged Arc Welding This technique is used for large diameter pipes and is efficient for achieving deep penetrations and high deposition rates. It is particularly useful in industrial settings where large-scale production is necessary.

Key Considerations in Hydraulic Pipe Welding

When welding hydraulic pipes, several factors must be considered to ensure a successful outcome

hydraulic pipe welding

- Material Compatibility Understanding the materials being welded is crucial. Different metals behave differently under heat, affecting the welding process. For instance, carbon steel requires different settings and filler material than stainless steel.

- Preparation Proper surface preparation is vital. Pipes should be cleaned and free of contaminants such as oil, rust, or dirt to achieve a strong weld. The fit-up of the pipes is equally important, as gaps can lead to weak points in the joint.

- Welding Parameters Factors such as voltage, amperage, and travel speed must be carefully controlled. Each material and thickness will require specific settings for optimal results.

- Post-Weld Treatment After welding, pipes often need to undergo a post-weld heat treatment. This process helps relieve internal stresses and improves the overall durability of the weld joint.

Applications in Various Industries

Hydraulic pipe welding is applied across multiple sectors

- Construction Heavy machinery, such as excavators and cranes, rely on hydraulics for operation. Reliable hydraulic pipes ensure these machines can perform under demanding conditions.

- Automotive Hydraulic systems in vehicles, particularly in braking and suspension systems, rely on welded pipes to maintain safety and performance.

- Aerospace In aerospace applications, reliability is critical. Hydraulic systems control flight surfaces and landing gear, necessitating exacting standards in pipe welding.

Conclusion

Hydraulic pipe welding is a specialized skill that plays a crucial role in ensuring the safety and functionality of hydraulic systems in various applications. Through careful selection of welding techniques, thorough preparation, and adherence to best practices, professionals can produce strong, reliable joints. As industries continue to evolve, the importance of skilled hydraulic pipe welding will only grow, further emphasizing the need for expertise in this vital domain.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024