-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 15, 2025 05:21 Back to list

DIN2605-2617 BUTT-WELDING FITTINGS Equal Tee/Reducing Tee

Inconel 625 tube fittings are the unsung heroes in industries that demand high-performance materials capable of withstanding extreme environments. These tube fittings are crafted from a nickel-chromium-molybdenum alloy known for its exceptional strength, corrosion resistance, and versatility, making it a preferred choice across various sectors including aerospace, chemical processing, and marine engineering.

Authoritativeness comes into play when discussing the compliance and certification of Inconel 625 tube fittings. These components are often manufactured in adherence to stringent standards such as ASTM B366 and ASME SB366. This assures potential users of their suitability and reliability for high-stakes applications. Trusted manufacturers provide comprehensive data sheets and support, underscoring their commitment to quality and customer safety. Such a dedication to standards not only positions these manufacturers as leaders in the field but also infuses confidence among engineers and procurement specialists when selecting tube fittings for crucial applications. Trustworthiness is further accentuated by the track record of Inconel 625 in real-world applications. Industries that deploy these tube fittings repeatedly observe minimal performance issues, even when subjected to cyclic loading or fluctuating operational conditions. The coherence of testimonials and case studies backing the alloy's dependability lends a substantial layer of trust. Industries consistently entrust their critical infrastructure to Inconel 625, reaffirming its role as a cornerstone of modern engineering solutions. In conclusion, Inconel 625 tube fittings are not merely components but are vital to the operational success and safety of complex systems across diverse industries. Their widespread endorsement by industry leaders and persistent success stories in challenging environments will continue to elevate their status in the market. When choosing materials for high-performance applications, the unparalleled capabilities of Inconel 625 make it an exceptional choice, promising reliability, cost-efficiency, and peace of mind for engineers worldwide.

Authoritativeness comes into play when discussing the compliance and certification of Inconel 625 tube fittings. These components are often manufactured in adherence to stringent standards such as ASTM B366 and ASME SB366. This assures potential users of their suitability and reliability for high-stakes applications. Trusted manufacturers provide comprehensive data sheets and support, underscoring their commitment to quality and customer safety. Such a dedication to standards not only positions these manufacturers as leaders in the field but also infuses confidence among engineers and procurement specialists when selecting tube fittings for crucial applications. Trustworthiness is further accentuated by the track record of Inconel 625 in real-world applications. Industries that deploy these tube fittings repeatedly observe minimal performance issues, even when subjected to cyclic loading or fluctuating operational conditions. The coherence of testimonials and case studies backing the alloy's dependability lends a substantial layer of trust. Industries consistently entrust their critical infrastructure to Inconel 625, reaffirming its role as a cornerstone of modern engineering solutions. In conclusion, Inconel 625 tube fittings are not merely components but are vital to the operational success and safety of complex systems across diverse industries. Their widespread endorsement by industry leaders and persistent success stories in challenging environments will continue to elevate their status in the market. When choosing materials for high-performance applications, the unparalleled capabilities of Inconel 625 make it an exceptional choice, promising reliability, cost-efficiency, and peace of mind for engineers worldwide.

Latest news

-

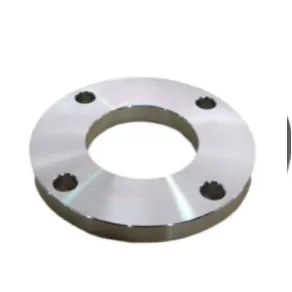

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024