-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 14, 2024 07:23 Back to list

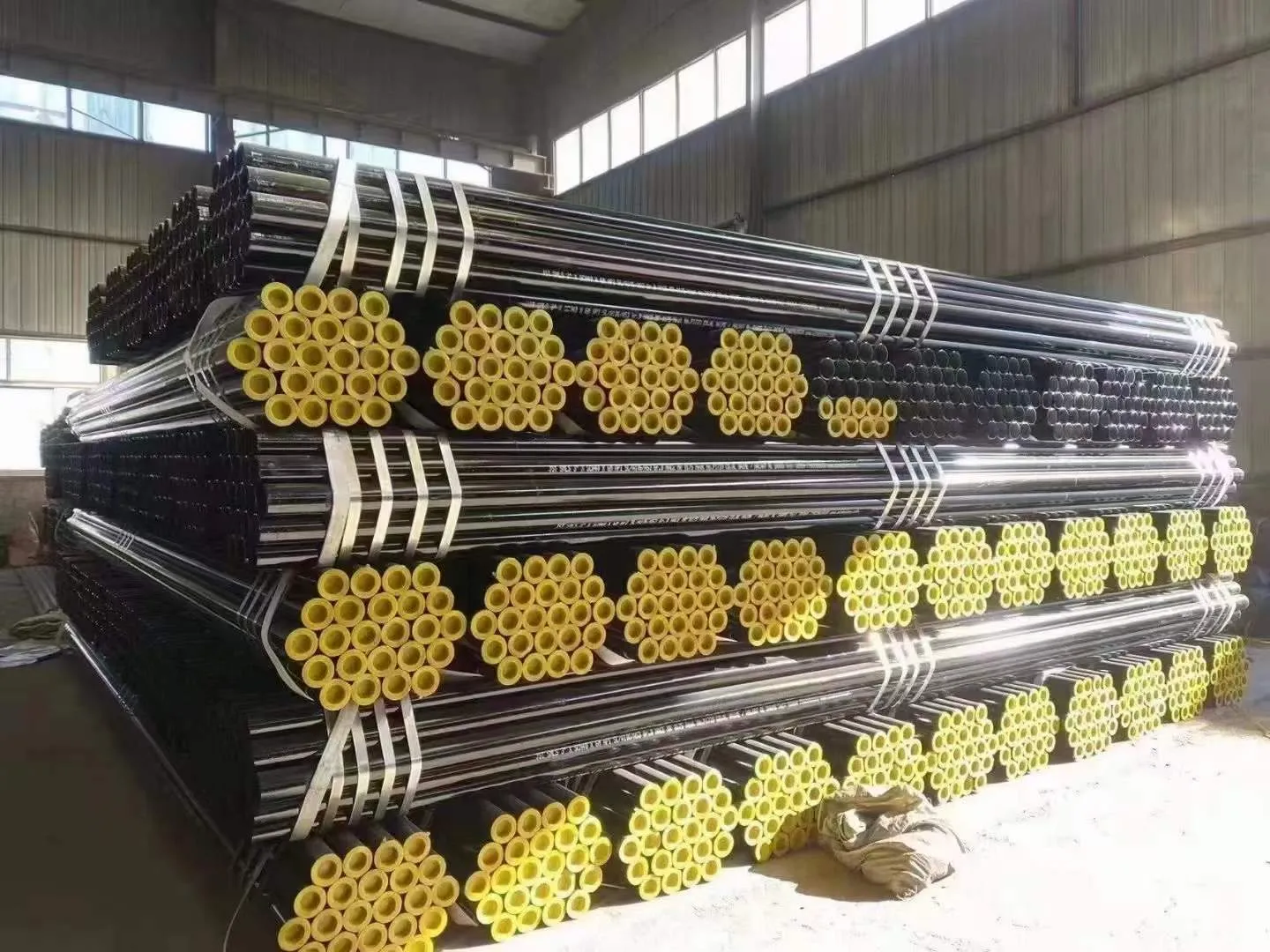

industrial metal pipe

The Versatility and Importance of Industrial Metal Pipes

In the realm of industrial applications, metal pipes stand as an essential component, offering reliability and efficiency across various sectors, including construction, manufacturing, and energy. These pipes serve a multitude of functions, from transporting fluids and gases to providing structural support. In this article, we will explore the significance of industrial metal pipes, their materials, various applications, and the future of this vital industry.

Material Composition

Industrial metal pipes are manufactured from several types of materials, each chosen for its unique properties. The most common materials used include

1. Steel This is the most prevalent material for industrial pipes, particularly carbon steel and stainless steel. Carbon steel is known for its strength and durability, making it ideal for transporting high-pressure fluids and gases. Stainless steel, on the other hand, provides excellent resistance to corrosion and is often used in environments where exposure to moisture and chemicals is common.

2. Aluminum Known for its lightweight properties, aluminum pipes are ideal for applications where weight is a critical factor. They are often used in aerospace and automotive industries, where reducing weight can lead to enhanced fuel efficiency and performance.

3. Copper Renowned for its excellent conductivity, copper pipes are frequently used in plumbing and HVAC systems. They can handle high-temperature applications and are resistant to corrosion, making them a reliable choice for water and gas transport.

4. PVC and other polymers While not traditionally classified as metal, these materials are also significant in the industrial pipe market. They offer lightweight alternatives with resistance to chemicals and corrosion. However, they generally can't withstand high-pressure applications as effectively as metal options.

Applications of Industrial Metal Pipes

The versatility of industrial metal pipes allows them to play crucial roles in a variety of applications

industrial metal pipe

1. Oil & Gas Industry Metal pipes are indispensable in the exploration, extraction, and transportation of oil and gas. High-strength steel pipes, often coated for corrosion resistance, are used in drilling operations and for transporting crude oil and natural gas over long distances.

2. Construction In the construction sector, metal pipes are used for both plumbing and as structural supports in buildings. Their strength ensures that they can bear heavy loads, making them key components in scaffolding, framework, and foundational structures.

3. Manufacturing Metal pipes facilitate the transportation of various substances, including liquids, powders, and gases, in manufacturing plants. As part of process systems, they ensure the efficient movement of materials and finished products throughout the production line.

4. HVAC Systems Copper and aluminum pipes are integral to heating, ventilation, and air conditioning systems. They help circulate refrigerants and are essential for maintaining climate control in residential, commercial, and industrial buildings.

5. Waste Management Water treatment facilities and waste management systems utilize metal pipes for transporting wastewater. Their durability and resistance to chemical corrosion help maintain system integrity and ensure efficient operation.

Future Perspectives

The industrial pipe industry is on the brink of significant advancements. With the push for sustainability, there is a growing emphasis on developing eco-friendly materials and practices. Innovations such as the production of pipes from recycled metals or the development of advanced alloys that minimize environmental impact are gaining traction.

Additionally, the integration of technology into the industrial pipe sector is transforming operations. Smart pipes equipped with sensors can monitor temperature, pressure, and flow, providing valuable real-time data that can enhance efficiency and safety. Predictive maintenance, backed by data analytics, can preemptively address issues, reducing downtime and repair costs.

Conclusion

Industrial metal pipes are foundational elements in a broad range of applications, providing essential services in critical industries. Their diverse materials and wide-ranging uses highlight their importance. As technology advances and sustainability becomes paramount, the future of industrial metal pipes promises to encompass innovations that enhance performance while minimizing environmental impact. By understanding the significance of these pipes, industries can better appreciate their role in supporting infrastructure and technological development, ensuring a more efficient and sustainable future.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024