-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 03, 2024 11:29 Back to list

Innovative Uses of JIS B2220 Flanges in Modern Industries

JIS B2220 flanges have long been recognized for their reliability and standardization in industrial piping systems. While they are widely used for traditional applications, modern industries have pushed their boundaries, finding innovative uses that highlight their adaptability. This article explores how JIS B2220 flanges are being leveraged in cutting-edge applications, while still emphasizing their standard dimensions and reliable performance.

The Foundation of JIS B2220 Flanges

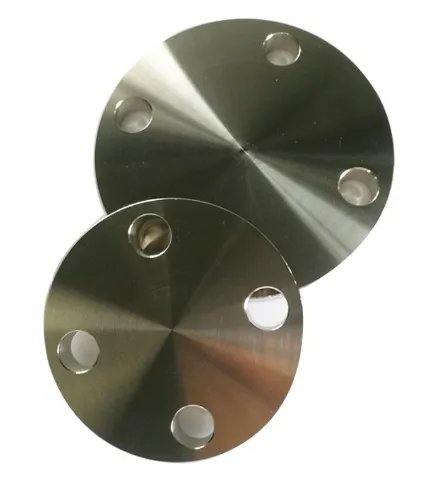

Jis b2220 10k are designed to the Japanese Industrial Standards (JIS), ensuring high precision and uniformity. These flanges are characterized by their metric dimensions, a feature that facilitates seamless integration in global projects. Available in various types such as slip-on, blind, and threaded, they cater to diverse connection needs.

Their pressure ratings, ranging from 5K to 63K, and material options such as carbon steel, stainless steel, and alloy steel make them adaptable to a variety of conditions. Whether exposed to high-pressure steam or corrosive chemicals, JIS B2220 flanges offer durability and reliability, making them suitable for innovative applications.

Renewable Energy Systems With JIS B2220 Flanges

One of the most exciting developments is the use of Jis b2220 5k in renewable energy projects. In offshore wind farms, these flanges are crucial for connecting underwater pipelines and equipment. Their corrosion-resistant material options, such as stainless steel, ensure durability in marine environments, while their precise dimensions provide secure seals under high pressure.

Hydrogen energy systems are another frontier where JIS B2220 flanges are making an impact. These flanges are used in hydrogen pipelines and storage systems, where leak prevention is critical. Their ability to withstand high pressures and compatibility with specialized gaskets ensures the safe transport and containment of hydrogen.

Advanced Water Treatment Technologies About JIS B2220 Flanges

Modern water treatment facilities are increasingly relying on JIS B2220 flanges to support complex processes. In desalination plants, these flanges connect pipes carrying high-salinity water under high pressure. The robust construction and material versatility of JIS B2220 flanges make them ideal for resisting corrosion caused by salt and other aggressive elements.

Additionally, in wastewater treatment, JIS B2220 flanges enable the integration of advanced filtration systems. Their precision allows for seamless connections between equipment, ensuring efficient flow and reducing the risk of leaks or contamination.

Integration into Smart Manufacturing About JIS B2220 Flanges

The rise of smart manufacturing has seen JIS B2220 flanges incorporated into automated systems. In robotics-driven assembly lines, these flanges are used to create secure and flexible piping networks that facilitate fluid transfer. Their compatibility with automation tools ensures quick and accurate installations, enhancing overall production efficiency.

Furthermore, their durability and low-maintenance requirements make them suitable for 24/7 operations in factories. By minimizing downtime and repair costs, JIS B2220 flanges contribute to the reliability and cost-effectiveness of modern manufacturing setups.

Applications in Aerospace and High-Tech Industries About JIS B2220 Flanges

Aerospace industries are leveraging the high-performance capabilities of JIS B2220 flanges in their ground-based and experimental systems. For instance, in rocket testing facilities, these flanges handle high-pressure gases and cryogenic liquids, where any failure could lead to catastrophic outcomes. Their precision engineering and material strength make them indispensable in such critical environments.

Similarly, high-tech industries such as semiconductor manufacturing utilize these flanges in ultra-pure water systems. The flanges' compatibility with corrosion-resistant materials ensures that the water remains uncontaminated, meeting the stringent standards required for chip fabrication.

Role in Modern Infrastructure About JIS B2220 Flanges

Infrastructure projects are evolving, and JIS B2220 flanges are playing a key role in modern developments. In smart cities, these flanges are used in integrated water, gas, and district heating systems. Their standardization simplifies the maintenance of these interconnected networks, ensuring reliability in urban utilities.

Underground transportation systems and tunnels also benefit from the use of JIS B2220 flanges. These flanges connect pipelines that transport air, water, or fire suppression materials, supporting safety and functionality in confined spaces.

The Future of JIS B2220 Flanges

The versatility of JIS B2220 flanges ensures that they will continue to find new applications as industries evolve. Innovations in materials, such as the development of lightweight alloys, could expand their use in fields like aviation and portable energy systems. Additionally, the integration of smart sensors into flange designs may enable real-time monitoring, further enhancing their utility in automated systems.

As global industries prioritize sustainability, JIS B2220 flanges are likely to play a significant role in projects aimed at reducing environmental impact. Their adaptability to green technologies and renewable energy systems positions them as a key component in the transition to cleaner energy and more efficient infrastructure.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024