-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Oct . 21, 2024 13:12 Back to list

Cost Analysis of Metal Pipes for Various Applications and Materials

Understanding the Cost of Metal Pipes Factors and Implications

Metal pipes are essential components in various industrial applications, ranging from construction to plumbing. Their durability, strength, and resistance to environmental factors make them a preferred choice over other materials. However, the cost of metal pipes can vary significantly based on several factors. Understanding these factors is crucial for businesses and individuals looking to purchase or utilize metal pipes in their projects.

1. Material Type

The cost of metal pipes largely depends on the type of material used. Common materials for metal pipes include steel, stainless steel, aluminum, and copper. Steel pipes are generally the most affordable option, making them popular in construction and manufacturing. However, they may rust if not adequately treated, leading to increased maintenance costs.

Stainless steel pipes, on the other hand, are more expensive than regular steel pipes due to their corrosion resistance and durability. This is particularly important in industries that require hygiene and cleanliness, such as food processing and pharmaceuticals. Aluminum pipes are lightweight and resistant to corrosion, making them suitable for applications where weight is a constraint, but they can also be pricier than steel options.

The specific dimensions of the pipe, including its diameter, thickness, and length, greatly influence its cost. Larger diameter pipes typically cost more than smaller ones due to the increased amount of material needed for their production. Similarly, thicker pipes designed for high-pressure applications are more expensive than standard pipes.

The length of the pipe can also impact the overall cost. Standard lengths may be more economical, while customized lengths can lead to additional manufacturing and shipping fees. Therefore, it's important to consider the specifications carefully to ensure cost-effectiveness.

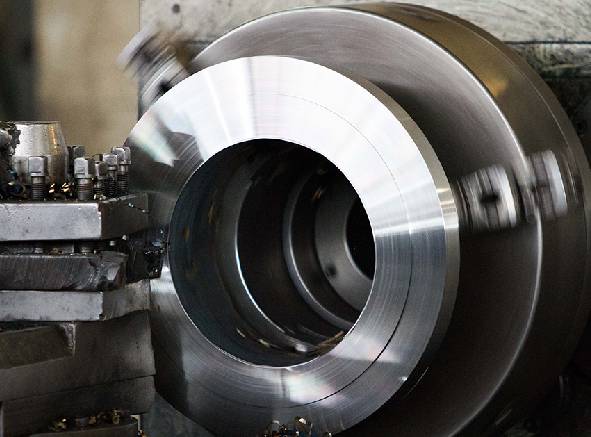

metal pipe cost

3. Manufacturing Process

The manufacturing process employed to create metal pipes can also affect their pricing. Pipes can be produced through various methods, including seamless and welded processes. Seamless pipes, which are manufactured without any joints or welds, are often perceived as stronger and more reliable, resulting in higher costs. Conversely, welded pipes, which are made by joining metal pieces together, tend to be more affordable. However, their strength can be compromised depending on the welding quality.

4. Market Demand and Economic Conditions

Like any commodity, the price of metal pipes is influenced by market demand and economic conditions. A rising demand for construction projects and infrastructure development can drive up the price of metal pipes, as supply struggles to meet the increased need. Additionally, fluctuations in global metal prices caused by economic factors can directly impact pipe costs. For instance, if the price of raw steel surges on the world market, manufacturers will likely pass those costs to consumers.

5. Shipping and Logistics

Shipping and logistics costs can significantly contribute to the overall expense of acquiring metal pipes. Pipes are heavy and often bulky items, leading to substantial transportation fees. The distance between the manufacturing facility and the point of purchase, as well as the shipping method chosen, can all affect the final cost. Businesses should account for these logistics when budgeting for their projects.

Conclusion

In summary, several factors influence the cost of metal pipes, including material type, pipe specifications, manufacturing processes, market conditions, and logistics. By understanding these elements, buyers can make informed decisions, ensuring they select the right pipes for their needs while staying within budget. As the demand for metal pipes continues to evolve, keeping abreast of these factors will be essential for anyone engaging in industries reliant on these vital materials.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024

-

DIN2605-2617 Butt-Welding Fittings LR/SR 45°/90°/180° Seamless/Weld

NewsApr.23,2024