-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 24, 2024 21:47 Back to list

mild steel flanges manufacturer

Understanding the Role of Mild Steel Flanges in Industrial Applications

Mild steel flanges are crucial components in various industrial applications, used primarily to connect pipes, valves, and other equipment. Their importance cannot be overstated, as they serve not just as a connection but also play a role in ensuring the integrity and efficiency of piping systems. In this article, we will explore what mild steel flanges are, their manufacturing process, advantages, and applications in diverse industries.

What are Mild Steel Flanges?

Mild steel flanges are circular disks with holes drilled around the circumference to allow for bolting to another flange or to a piece of equipment. They can be flat or raised face, depending on the application. The term mild steel refers to a type of steel alloy that contains low carbon content, typically up to 0.25%. This composition provides mild steel with a good combination of strength, ductility, and weldability, making it a popular choice for fabricating flanges.

Manufacturing Process

The manufacturing of mild steel flanges involves several steps, ensuring that the final product meets strict industry standards. The process begins with selecting high-quality mild steel, which typically undergoes a melting and refining process to remove impurities.

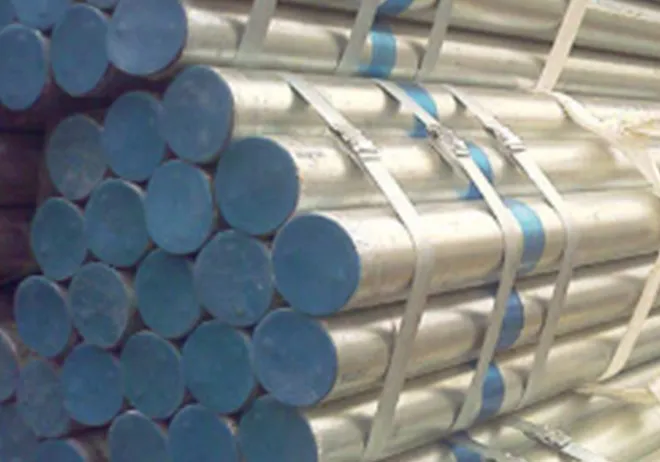

Next, the molten steel is cast into slabs or billets, which are then heated and rolled into flat plates of the desired thickness. From these plates, flanges are cut using either laser cutting or plasma cutting methods. The resulting shape is then subjected to several finishing processes, such as machining, drilling, and surface treatment. These finishing touches ensure that the flanges have the correct dimensions and surface characteristics to facilitate a tight seal when installed.

Quality control is paramount throughout this process, with rigorous testing to ensure the flanges can withstand the pressures and conditions they will face in service. Testing may include checks for tensile strength, ductility, and fatigue resistance, ensuring reliability.

Advantages of Mild Steel Flanges

Mild steel flanges come with a host of advantages that make them an attractive choice for various applications

1. Cost-Effectiveness Due to the relatively low cost of mild steel compared to other materials, mild steel flanges are more economical, making them a popular choice for businesses looking to minimize costs without sacrificing quality.

mild steel flanges manufacturer

2. Versatility These flanges can be used in various environments, including chemical processing, oil and gas, water supply, and construction. Their adaptability extends to different temperature and pressure levels, broadening their scope of application.

3. Ease of Installation The design of mild steel flanges allows for straightforward installation and removal. This feature is particularly advantageous in maintenance and repair scenarios, as it reduces downtime.

4. Strong and Durable Despite being known for its malleability, mild steel provides sufficient strength for many applications, making it ideal for high-pressure systems.

5. Weldability Mild steel flanges can be easily welded to pipes and other components, facilitating a seamless integration into the piping system.

Applications in Various Industries

Mild steel flanges find applications across several industries

- Oil and Gas They are extensively used in pipelines to connect different sections and equipment, ensuring the safe transportation of oil and gas.

- Water Treatment In municipal water treatment facilities, mild steel flanges are employed to connect valves and pipes, playing a vital role in the distribution of clean water.

- Manufacturing Many industrial plants utilize mild steel flanges in machinery setups, ensuring efficient fluid transfer.

- Construction In construction, these flanges are often used to connect structural components, providing stability and safety to various structures.

In conclusion, mild steel flanges are essential elements in many industrial applications. Their cost-effectiveness, versatility, and durability make them a staple in different sectors, ensuring efficient and reliable operations. With an understanding of their manufacturing processes, advantages, and applications, businesses can make informed decisions about their piping system needs, ultimately contributing to safer and more efficient industrial operations.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024