-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 01, 2024 11:49 Back to list

Designing Efficient Non-Concentric Reducers for Improved Fluid Flow in Industrial Applications

Understanding Non-Concentric Reducers Applications and Benefits

Non-concentric reducers, essential components in piping systems, play a pivotal role in seamlessly transitioning between pipes of different diameters. Unlike concentric reducers, which have a common centerline, non-concentric reducers possess an off-centered design. This unique feature allows for more flexibility in installation, particularly in tight spaces where standard concentric reducers may not fit effectively.

Understanding Non-Concentric Reducers Applications and Benefits

One of the significant advantages of non-concentric reducers is their ability to minimize turbulence. When fluids transition from a larger diameter to a smaller one, excessive turbulence can lead to losses in pressure and flow rate. Non-concentric reducers are designed to reduce these adverse effects, ensuring smoother transitions and more controlled flow dynamics. This not only enhances the overall efficiency of the system but also extends the lifespan of the piping infrastructure.

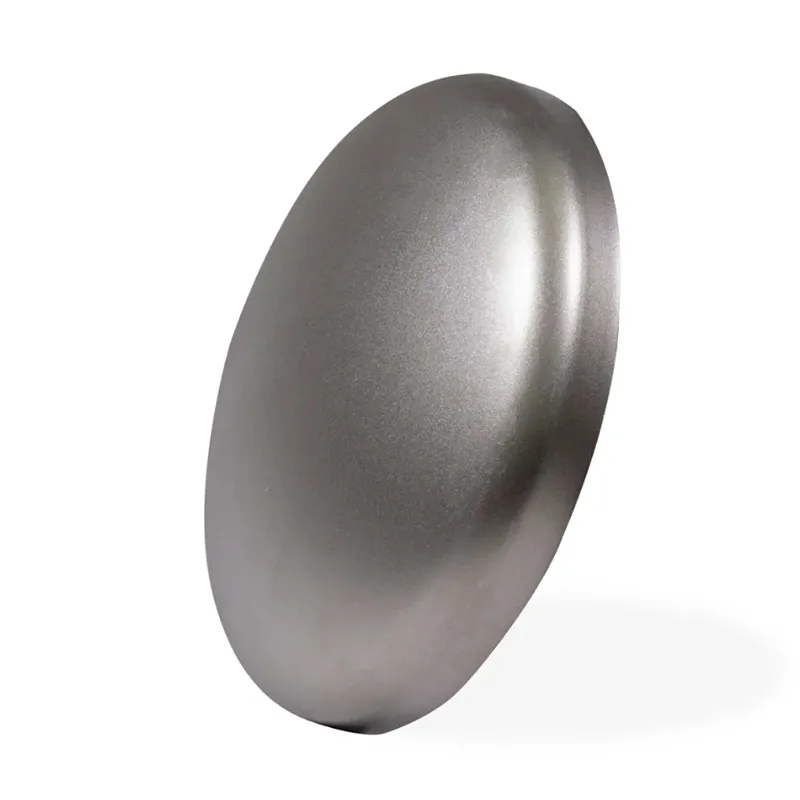

non concentric reducer

Moreover, non-concentric reducers offer versatility in design and installation. They can be fabricated from various materials, including stainless steel, carbon steel, and plastic, allowing them to meet specific environmental and operational requirements. Their design flexibility accommodates a wide range of applications, from high-pressure gas systems to low-pressure liquid transport.

Another noteworthy aspect is their contribution to space-saving designs. In situations where space is limited, non-concentric reducers can be installed in orientations that would be impossible for their concentric counterparts. This capability is particularly beneficial in retrofitting projects and complex piping layouts, where maximizing available space is crucial.

In conclusion, non-concentric reducers are indispensable for modern piping systems, providing solutions for efficient fluid management while offering significant advantages in terms of optimizing flow dynamics, versatility, and spatial efficiency. Engineers and designers must consider these components to achieve reliable and effective piping solutions tailored to specific industry needs. As industrial processes evolve, so too will the technology and applications surrounding non-concentric reducers, solidifying their role in the future of fluid transport systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024