-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jun . 14, 2024 12:02 Back to list

Oil & Gas Flange Types

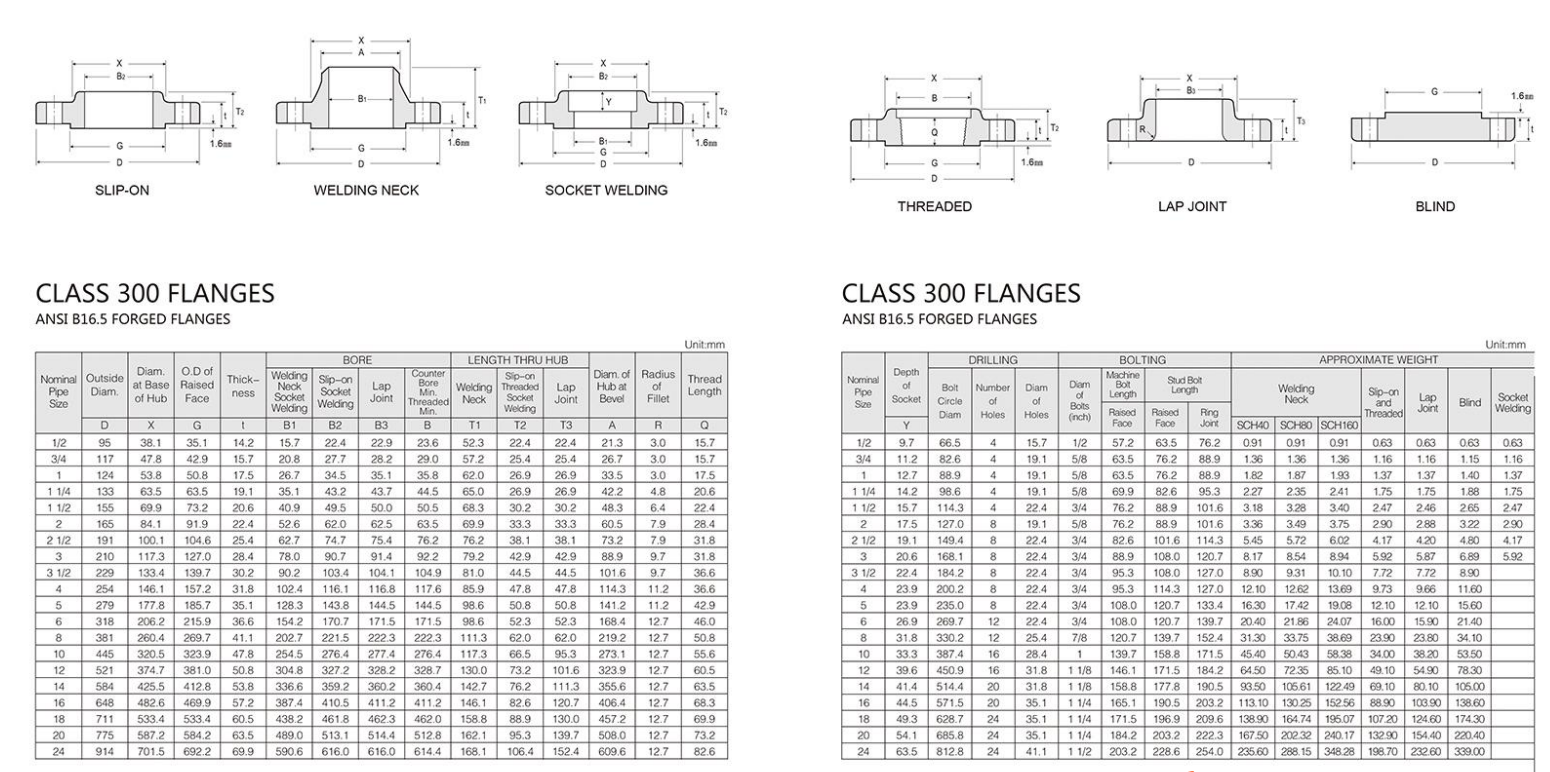

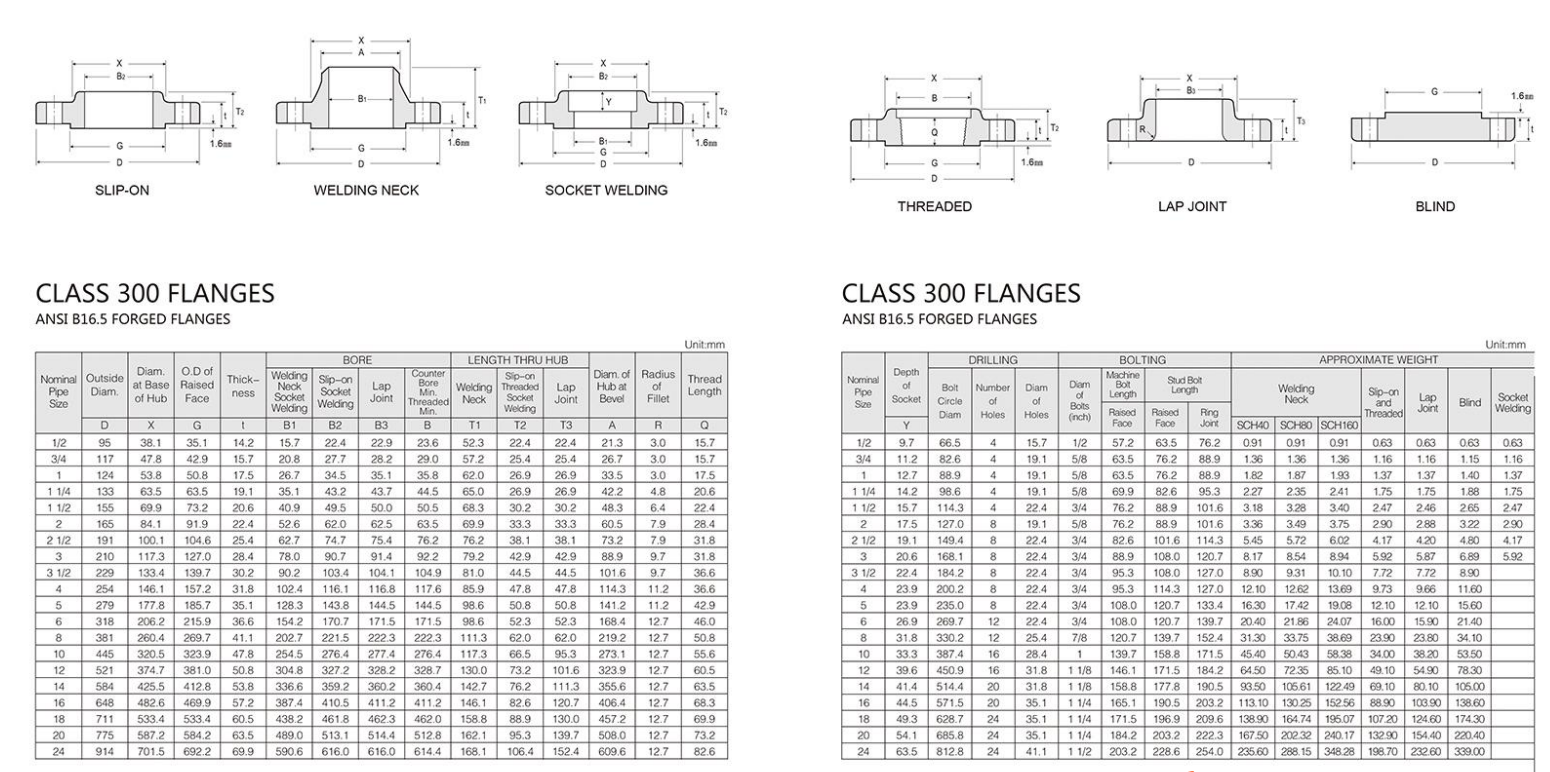

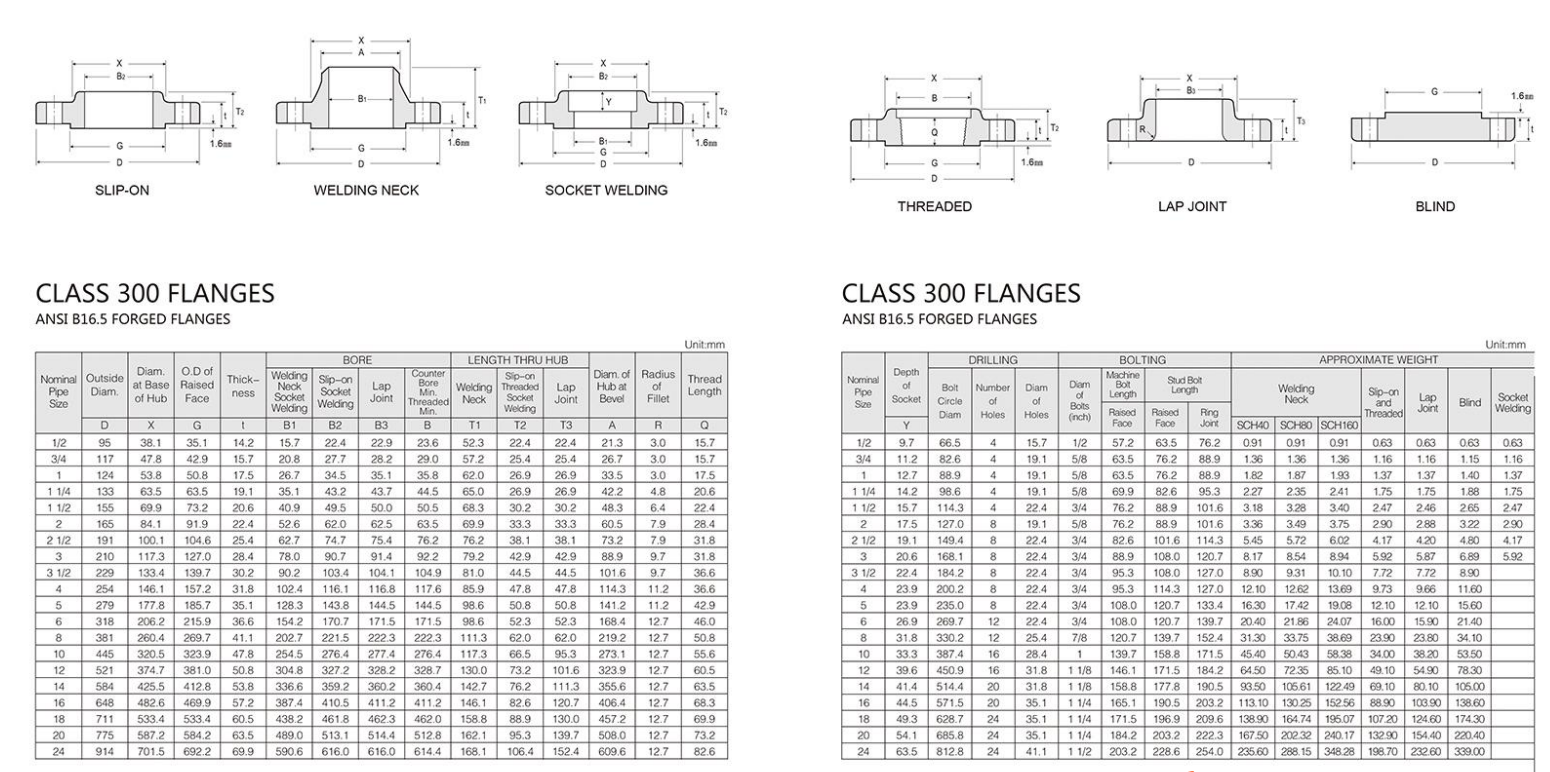

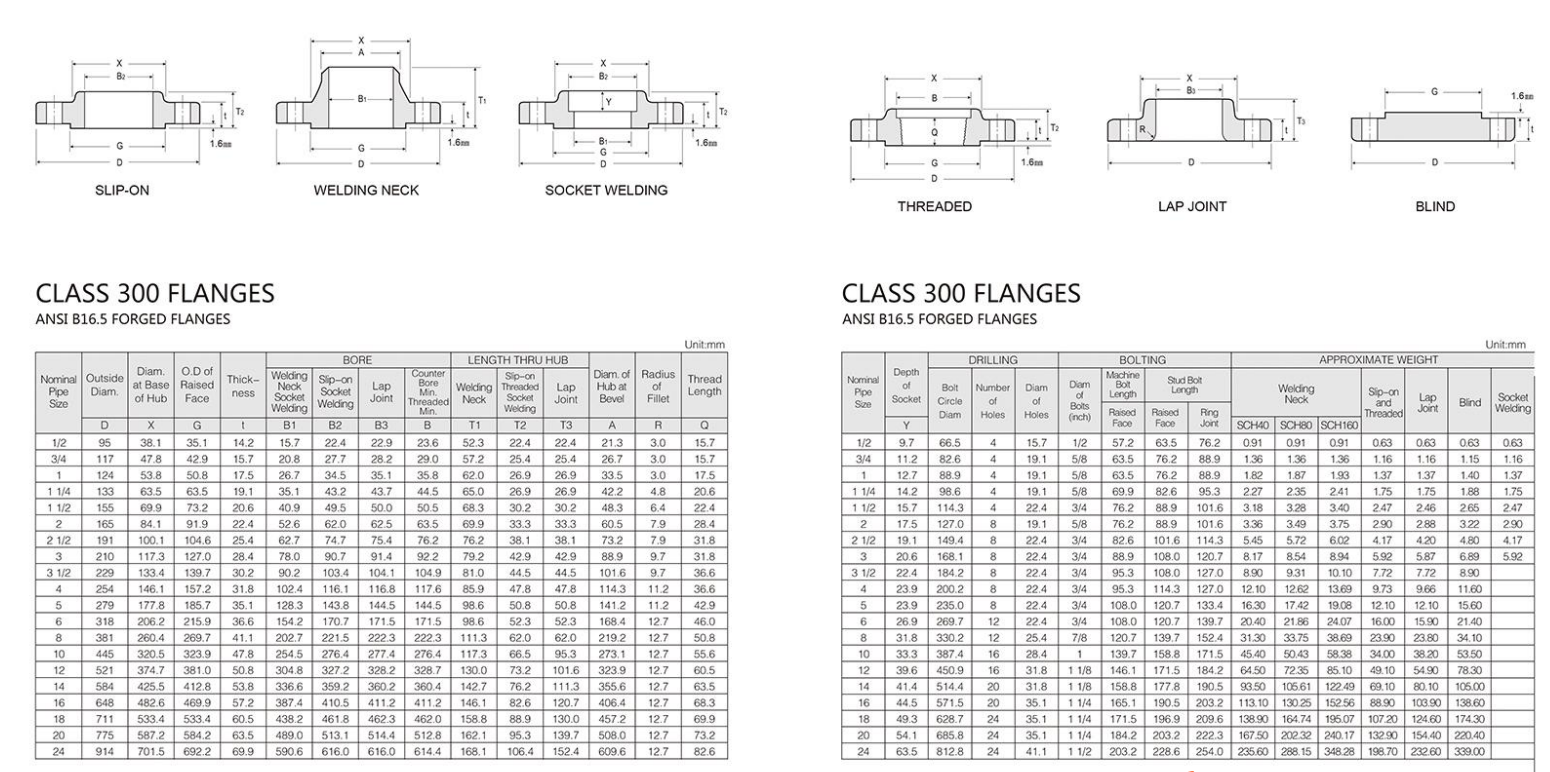

The oil and gas industry is a vital sector that plays a crucial role in the global economy. It involves the exploration, production, transportation, refining, and distribution of crude oil and natural gas. The industry requires a wide range of equipment and components to ensure the safe and efficient operation of its facilities. One such essential component is the flange, which is used extensively in various aspects of the oil and gas industry.

Flanges are circular metal plates with holes drilled in them, which are used to connect pipes, valves, and other equipment together. They provide a secure and reliable seal, preventing leaks and ensuring the integrity of the system. Flanges are typically made from high-strength materials such as carbon steel, stainless steel, or alloy steel, depending on the specific requirements of the application.

In the oil and gas industry, flanges are used in a variety of applications, including pipelines, wellheads, refineries, and storage tanks. They are used to connect sections of pipe, attach valves and pumps, and create barriers to contain hazardous fluids. The size and type of flange used depend on the specific requirements of the application, including the pressure and temperature ratings, the diameter of the pipes being connected, and the type of fluid being handled.

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility types of flanges used in oil and gas industry. They can be customized to meet the specific needs of each application, making them suitable for use in a wide range of environments and conditions. Flanges can also be easily repaired or replaced if they become damaged or worn out, ensuring the continued reliability of the system.

However, the use of flanges in the oil and gas industry also presents some challenges. For example, flanges can be subject to high levels of corrosion and wear due to exposure to harsh chemicals and extreme temperatures. This can reduce their lifespan and require regular maintenance and replacement. In addition, the installation and maintenance of flanges can be complex and time-consuming, requiring specialized knowledge and skills.

In conclusion, flanges are a critical component in the oil and gas industry, providing a secure and reliable means of connecting and sealing pipes and equipment. They are versatile, customizable, and can be easily repaired or replaced, but must be carefully selected and maintained to ensure their longevity and effectiveness. As the industry continues to grow and evolve, the demand for high-quality, durable flanges will remain strong.

types of flanges used in oil and gas industry. They can be customized to meet the specific needs of each application, making them suitable for use in a wide range of environments and conditions. Flanges can also be easily repaired or replaced if they become damaged or worn out, ensuring the continued reliability of the system.

However, the use of flanges in the oil and gas industry also presents some challenges. For example, flanges can be subject to high levels of corrosion and wear due to exposure to harsh chemicals and extreme temperatures. This can reduce their lifespan and require regular maintenance and replacement. In addition, the installation and maintenance of flanges can be complex and time-consuming, requiring specialized knowledge and skills.

In conclusion, flanges are a critical component in the oil and gas industry, providing a secure and reliable means of connecting and sealing pipes and equipment. They are versatile, customizable, and can be easily repaired or replaced, but must be carefully selected and maintained to ensure their longevity and effectiveness. As the industry continues to grow and evolve, the demand for high-quality, durable flanges will remain strong.

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility

One of the key advantages of using flanges in the oil and gas industry is their versatility types of flanges used in oil and gas industry. They can be customized to meet the specific needs of each application, making them suitable for use in a wide range of environments and conditions. Flanges can also be easily repaired or replaced if they become damaged or worn out, ensuring the continued reliability of the system.

However, the use of flanges in the oil and gas industry also presents some challenges. For example, flanges can be subject to high levels of corrosion and wear due to exposure to harsh chemicals and extreme temperatures. This can reduce their lifespan and require regular maintenance and replacement. In addition, the installation and maintenance of flanges can be complex and time-consuming, requiring specialized knowledge and skills.

In conclusion, flanges are a critical component in the oil and gas industry, providing a secure and reliable means of connecting and sealing pipes and equipment. They are versatile, customizable, and can be easily repaired or replaced, but must be carefully selected and maintained to ensure their longevity and effectiveness. As the industry continues to grow and evolve, the demand for high-quality, durable flanges will remain strong.

types of flanges used in oil and gas industry. They can be customized to meet the specific needs of each application, making them suitable for use in a wide range of environments and conditions. Flanges can also be easily repaired or replaced if they become damaged or worn out, ensuring the continued reliability of the system.

However, the use of flanges in the oil and gas industry also presents some challenges. For example, flanges can be subject to high levels of corrosion and wear due to exposure to harsh chemicals and extreme temperatures. This can reduce their lifespan and require regular maintenance and replacement. In addition, the installation and maintenance of flanges can be complex and time-consuming, requiring specialized knowledge and skills.

In conclusion, flanges are a critical component in the oil and gas industry, providing a secure and reliable means of connecting and sealing pipes and equipment. They are versatile, customizable, and can be easily repaired or replaced, but must be carefully selected and maintained to ensure their longevity and effectiveness. As the industry continues to grow and evolve, the demand for high-quality, durable flanges will remain strong. Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024