-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 29, 2024 00:13 Back to list

Optimizing Equipment Longevity with Advanced Wear Plate Solutions for Heavy-Duty Applications

Understanding Wear Plates Essential Components for Enhanced Durability

In various industrial applications, the need for durable and robust components is paramount. One of the critical elements often overlooked is the use of wear plates. These specialized plates are designed to protect machinery and equipment from wear and tear caused by abrasive materials, friction, and impact. When discussing wear plates, it’s essential to understand their composition, applications, benefits, and maintenance to ensure longevity and efficiency in operations.

Composition and Types of Wear Plates

Wear plates are typically made from high-performance materials that can withstand extreme conditions. Common materials include steel, stainless steel, polyurea, and other composites. The hardness and thickness of these plates can vary based on the specific requirements of the application.

1. Steel Wear Plates High-carbon steel is frequently used for its toughness and resistance to wear, making it ideal for heavy-duty applications in mining, construction, and manufacturing.

2. Stainless Steel Plates These are used in environments prone to corrosion. Their resistance to rust and staining makes them suitable for food processing, chemical processing, and other applications where hygiene is essential.

3. Polyurethane Wear Plates These are lighter and provide excellent resistance to abrasion and impact. They are commonly used in applications such as conveyor systems where flexibility and noise reduction are desired.

4. Ceramic Wear Plates These offer superior hardness and abrasion resistance, often utilized in high-wear areas of equipment.

Applications of Wear Plates

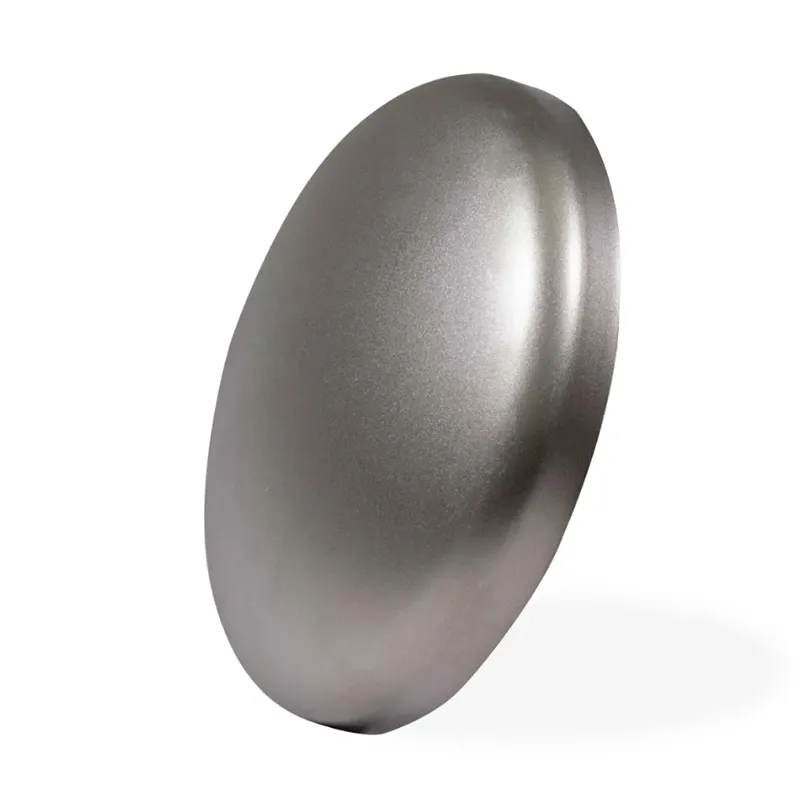

wear plates

Wear plates are employed across a range of industries, including mining, construction, agriculture, and manufacturing. They are commonly found in

- Conveyor Systems Wear plates protect the surfaces of conveyors from debris and abrasion, extending the lifespan of the equipment. - Excavators and Loaders These machines often encounter harsh conditions, and wear plates shield critical components from damage, ensuring efficient operation. - Hoppers and Chutes In bulk material handling, wear plates help prevent material buildup and protect against wear caused by the constant flow of abrasive materials. - Pumps and Valves In fluid handling systems, wear plates can reduce turbulence and erosion, improving the overall efficiency of the system.

Benefits of Using Wear Plates

The implementation of wear plates provides numerous benefits. They significantly reduce maintenance costs by prolonging the life of the underlying equipment, leading to less downtime and increased productivity. Furthermore, wear plates enhance safety in the workplace by minimizing the risk of equipment failure that could lead to accidents.

Additionally, wear plates can be customized to fit specific applications, offering versatility that can be crucial for industries with unique needs. The right wear plate can optimize performance, contributing to a more efficient operation.

Maintenance and Care

Despite their durability, wear plates require regular inspections and maintenance to ensure they perform optimally. Operators should periodically check for signs of wear or damage and replace plates as necessary. Keeping the equipment clean and free from excessive debris also contributes to prolonging the life of wear plates.

In conclusion, wear plates are vital components that contribute significantly to the efficiency and longevity of machinery across various industries. Understanding their types, applications, and maintenance requirements is essential for businesses looking to enhance productivity and reduce operational costs. By investing in the right wear plates, companies can ensure their equipment withstands the rigors of everyday use, leading to smoother operations and better overall performance.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024