-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 10, 2024 12:48 Back to list

Pipe Fittings with Internal and External Threads - Comprehensive Guide

Understanding Pipe Fittings with Internal and External Threads

Pipe fittings play a crucial role in various plumbing and piping systems, ensuring that fluid transport remains efficient, safe, and reliable. Among the different types of fittings, those featuring internal and external threads are especially significant for making secure connections between pipes and other components.

Internal Threads

Internal threads are grooves cut into a fitting's interior surface, which allow for a male fitting or pipe with corresponding external threads to be screwed in. This design is commonly found in fittings like female connectors, which enable a tight seal and prevent leaks in fluid systems. Internal threads are essential for maintaining the integrity of connections, as they provide a robust engagement when coupled with external threads. The precision of these threads ensures that the connection can withstand various pressures commonly encountered in plumbing applications.

External Threads

Conversely, external threads refer to the ridges formed on the outer surface of a pipe or fitting. Male fittings, equipped with external threads, are designed to fit into internal-threaded counterparts. This type of configuration is vital in scenarios where two pipes need to be joined or when a pipe connects to various devices, such as valves or gauges. The friction between the mating surfaces of internal and external threads allows for a secure fit, reducing the potential for fluid leaks.

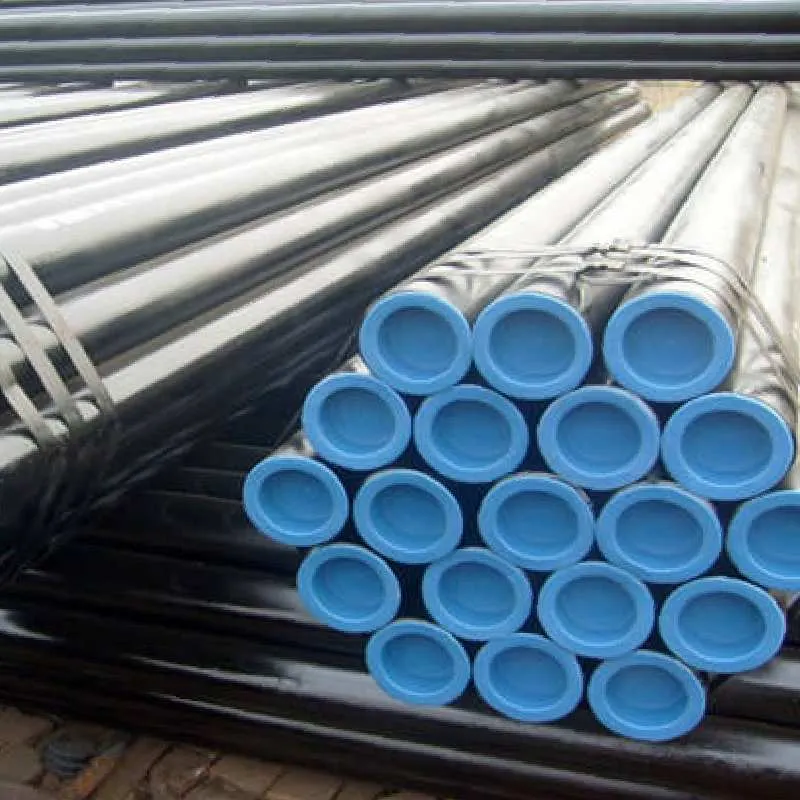

pipe fitting with internal and external threads

Applications

Pipe fittings with internal and external threads are widely used across numerous industries, including residential plumbing, commercial construction, and manufacturing. They are essential in systems conveying water, gas, and other fluids. Proper selection and installation of these fittings ensure optimal performance and longevity of the piping systems.

Importance of Quality

When dealing with pipe fittings, the quality of the materials used is paramount. High-grade materials resistant to corrosion and wear can significantly enhance the durability of fittings and the overall plumbing system. Additionally, using fittings that conform to industry standards is crucial in guaranteeing compatibility with other components and minimizing failure risks.

Conclusion

In summary, pipe fittings with internal and external threads are indispensable components in fluid transport systems. Understanding their functionality allows for better decision-making when designing or repairing plumbing networks. Whether for installation purposes or maintenance, knowledge of these fittings can lead to more efficient, safe, and durable piping systems, ultimately ensuring the effective transfer of liquids and gases in diverse applications.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024