-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 18, 2024 03:08 Back to list

Pipe Flanges and Plates for Effective Piping Solutions and Connections

Understanding Pipe Flange Plates An Overview

Pipe flange plates play a crucial role in various piping systems, particularly in industries such as oil and gas, chemical manufacturing, and water treatment. Flanges serve as the connectors between pipes, allowing for a robust and leak-proof attachment that is essential for maintaining the integrity of a system.

Flange plates are typically made from materials like stainless steel, carbon steel, or other alloys, chosen based on the specific requirements of the application, including temperature, pressure, and the type of fluid being transported. Their strength and durability are vital, as they must withstand harsh operating conditions while providing a reliable seal.

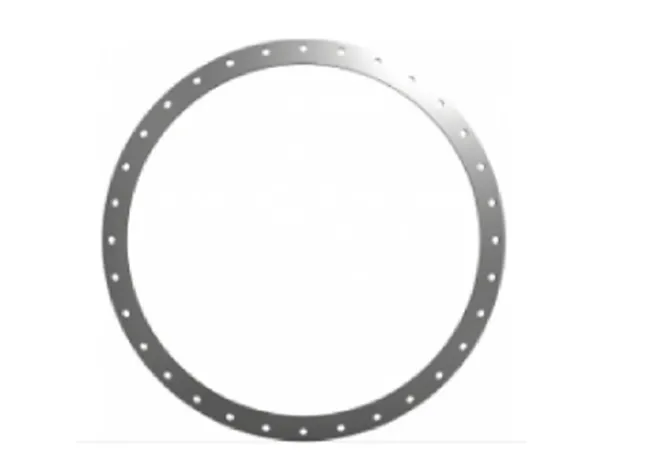

The design of a pipe flange plate usually includes a flat, circular disc with holes around the perimeter for bolting to another flange on a pipe, valve, or other equipment

. Standardized sizes and specifications—such as ANSI, ASME, and DIN—ensure compatibility between different components, making it easier for engineers to design and implement piping systems that are efficient and safe.pipe flange plate

There are several types of flanges, including weld neck, slip-on, blind, and threaded flanges, each with its particular use cases. For instance, weld neck flanges are favored for high-pressure applications because of their ability to handle stress and ease of welding, while slip-on flanges are often used in lower-pressure environments due to their simpler installation process.

Proper installation and maintenance of pipe flange plates are critical for preventing leaks and failures. It's essential to use the correct gasket material to provide a seal between the flanges, as well as to ensure that the bolts are tightened to the specified torque to avoid joint separation or deformation. Regular inspections can help identify any potential issues before they escalate, contributing to the longevity and reliability of the piping system.

In summary, pipe flange plates are integral components of modern piping systems, facilitating connections and ensuring safe and efficient fluid transport. Understanding their design, types, and maintenance is essential for engineers and technicians who work in fields where fluid dynamics play a pivotal role. As industries continue to advance, the importance of high-quality flange plates will only grow, reinforcing their place in the engineering landscape.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024