-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 24, 2024 02:28 Back to list

pipe floor flange

Understanding Pipe Floor Flanges Essential Components in Piping Systems

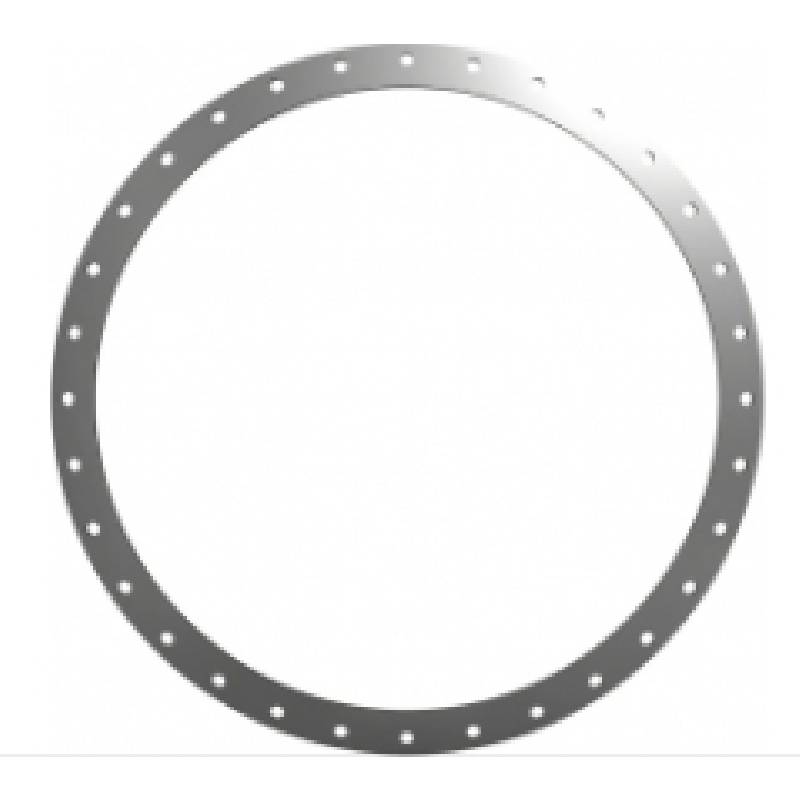

In the world of industrial piping systems, the importance of high-quality components cannot be overstated. Among these components, pipe floor flanges play a vital role in ensuring the integrity and efficiency of various installations. A pipe floor flange is specifically designed to provide a secure and stable connection between pipes and the floor, making it an essential fixture in many applications, from plumbing to chemical processing.

What is a Pipe Floor Flange?

A pipe floor flange, often referred to as a flange or floor flange, is a flat component that typically has a circular or square shape. It is used to connect pipes to a flat surface, such as a concrete floor or base, allowing for a sturdy attachment that is crucial for overall system stability. These flanges can be made from various materials, including stainless steel, carbon steel, and plastic, depending on the requirements of the application, such as corrosion resistance, load-bearing capacity, and environmental conditions.

Applications of Pipe Floor Flanges

Pipe floor flanges are found in a wide range of applications across different industries. In commercial plumbing, they are commonly used to anchor pipes that supply water or gas services, providing a secure mounting point that can accommodate the weight and movement of the plumbing system.

In manufacturing and processing plants, floor flanges are essential for connecting pipelines that transport chemicals, oils, or other fluids. The durability and strength of the flange are critical to prevent leaks and ensure safety in installations where hazardous materials are involved.

Additionally, in the construction and engineering sectors, floor flanges serve as integral components when constructing frameworks for various building services, including HVAC systems, electrical conduits, and drainage systems.

Installation and Maintenance

pipe floor flange

Installing a pipe floor flange requires careful consideration of several factors, including alignment, load distribution, and the specific environment in which it will be used. Proper installation involves drilling holes in the designated spots on the floor, fitting the flange, and then securing it with appropriate fasteners. It is essential to use appropriate sealing materials to prevent leaks, especially in applications dealing with liquids or gases.

Regular maintenance of pipe floor flanges is also crucial. Over time, flanges can loosen due to vibration, thermal expansion, and other operational stresses. Consequently, inspections should be conducted periodically to ensure that they remain securely fastened and free from corrosion or mechanical damage.

Benefits of Using Pipe Floor Flanges

The use of pipe floor flanges provides several benefits, making them indispensable components in various piping applications. One of the primary advantages is their ability to facilitate secure, stable connections, which significantly reduces the risk of leaks and failures in the piping system.

Moreover, floor flanges enhance the ease of maintenance. If a section of the piping needs to be replaced or repaired, a flange can simplify the process by allowing for quick disconnections without extensive dismantling of the entire system.

Additionally, pipe floor flanges contribute to the overall structural integrity of the installation, mitigating the potential for pipe sagging or misalignment that could lead to more significant issues over time.

Conclusion

In conclusion, pipe floor flanges are essential components that provide stability and safety in various piping systems across multiple industries. Their ability to create secure connections, coupled with their ease of installation and maintenance, makes them invaluable in ensuring the longevity and efficiency of pipelines. As industries continue to evolve and expand, the importance of high-quality pipe floor flanges will remain a critical component in meeting the demands of modern infrastructure and manufacturing.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024