-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 20, 2024 19:36 Back to list

pn16 class 150 flange

Understanding PN16 Class 150 Flanges A Technical Overview

Flanges play a pivotal role in piping systems, providing a secure means of connecting various segments, whether they are pipes, valves, or pumps. Among the different classifications and standards that govern flanges, PN16 and Class 150 are two of the most widely recognized terms in the engineering and construction industries. This article delves into the intricacies of PN16 Class 150 flanges, their applications, specifications, and advantages.

What are PN16 and Class 150?

The terms PN16 and Class 150 relate to different pressure rating systems, each adopted in various regions and industries. PN16 is a designation rooted in the metric system, where PN stands for Pressure Nominal and the number indicates the maximum allowable pressure (in bar) at a temperature of 20°C. Thus, a PN16 flange can handle a pressure of up to 16 bar.

On the other hand, Class 150 originates from the American National Standards Institute (ANSI) and is primarily used in the United States. The Class rating signifies the pressure-temperature relationship for flanges, with Class 150 typically rated for approximately 150 pounds per square inch (psi) at ambient temperatures.

Key Specifications

When it comes to PN16 Class 150 flanges, there are critical specifications to consider

1. Material Composition Flanges can be composed of various materials, including carbon steel, stainless steel, and alloys. The choice of material impacts the flange's resistance to corrosion, strength, and overall durability.

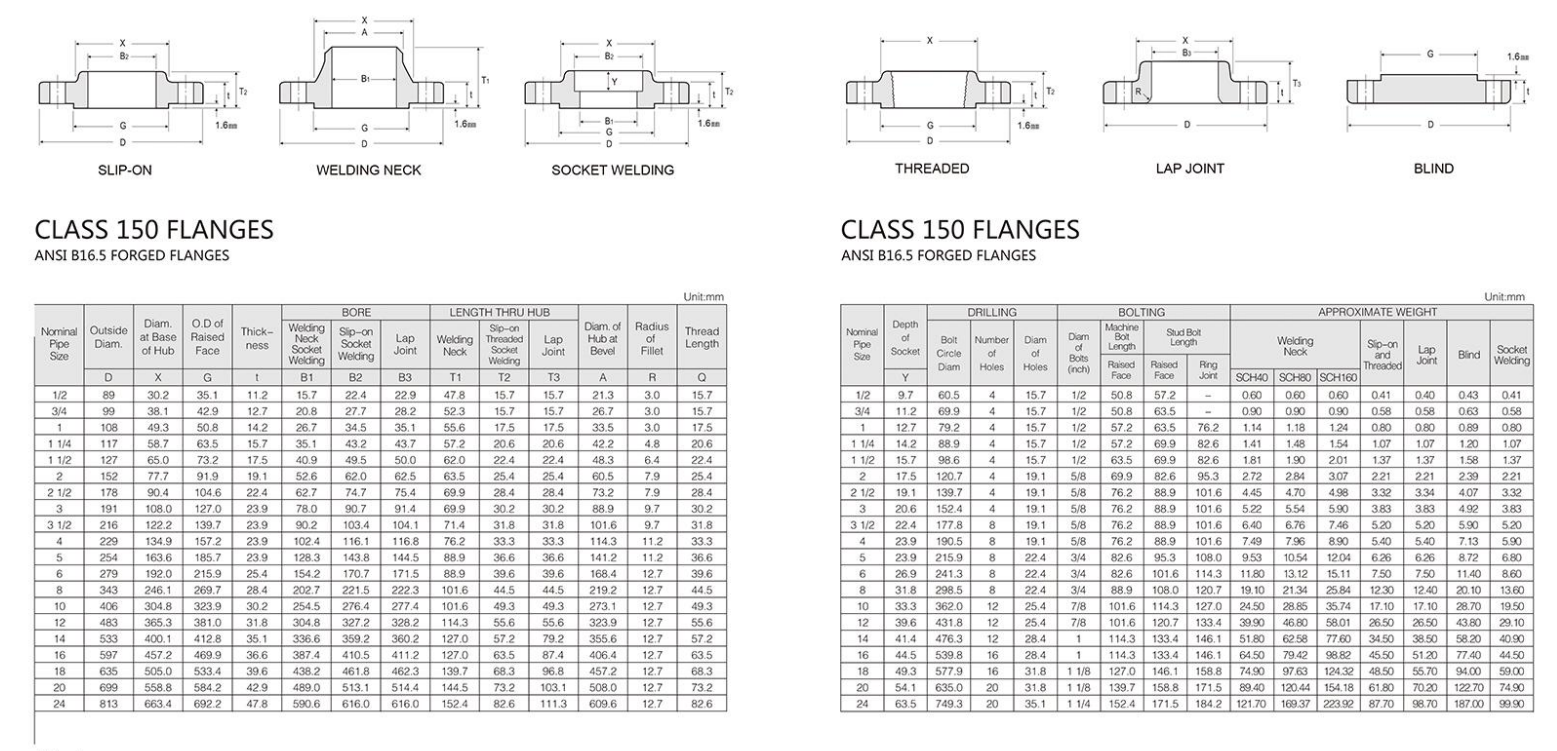

2. Dimensions The dimensions of flanges—such as diameter, thickness, and bolt hole pattern—must align with established standards. For example, the ASME B16.5 standard outlines the dimensional specifications for Class 150 flanges.

3. Bolt Patterns The arrangement of bolt holes on the flange surface is crucial for ensuring a tight seal. PN16 flanges often feature a specific bolt circle diameter that corresponds to the nominal pipe size.

4. Surface Finish The surface finish of flanges affects the sealing capability. Smooth surfaces improve the gasket's performance, while rough surfaces may lead to leakage.

5. Gasket Compatibility The choice of gasket material must complement the flange material and application to ensure a reliable seal under various operating conditions.

Applications

pn16 class 150 flange

PN16 Class 150 flanges are used in a wide range of applications across different industries

- Water Supply Systems Their ability to withstand moderate pressures makes them suitable for water pipelines, irrigation systems, and potable water supply installations.

- Chemical Processing In chemical plants, these flanges can connect pipelines carrying non-corrosive fluids, ensuring safety and compliance with industry regulations

.- HVAC Systems In heating, ventilation, and air conditioning systems, PN16 Class 150 flanges are utilized in various connections, providing a reliable and efficient method for joining components.

- Oil and Gas While typically used in less demanding applications, these flanges can also be found in certain parts of oil and gas pipelines, especially in low-pressure systems.

Advantages of PN16 Class 150 Flanges

1. Ease of Use Their standardized sizes and configurations make PN16 Class 150 flanges easy to source and integrate into existing systems.

2. Cost-Effectiveness As a widely used standard, these flanges offer a balance between performance and cost, making them a popular choice in diverse applications.

3. Versatility Their compatibility with various materials and the ability to withstand different pressures allow for flexibility in design and engineering.

4. Robust Performance With the right gasket and installation techniques, PN16 Class 150 flanges can provide leak-free connections that maintain structural integrity over time.

Conclusion

Understanding the specifications, applications, and benefits of PN16 Class 150 flanges is essential for engineers, designers, and procurement professionals involved in piping system design and installation. Their robustness, versatility, and wide acceptance make them vital components in many industrial applications. Selecting the right flange not only ensures safety and compliance with regulations but also enhances the overall efficiency of the piping system.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024