-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 25, 2025 01:01 Back to list

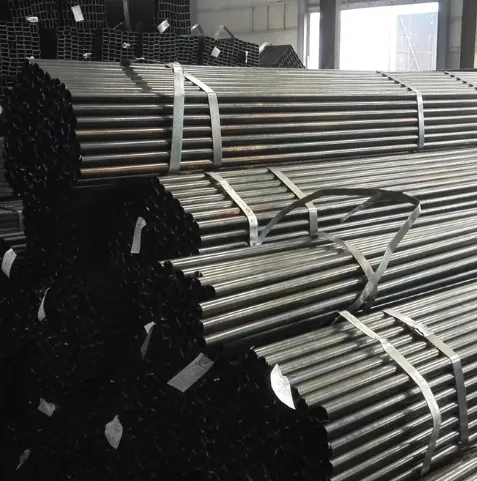

Premium Seamless Steel Pipe for Durable Applications

Official Website: https://www.ylsteelfittings.com

Phone: +86 13303177267

Email: admin@ylsteelfittings.com

Mobile: +86 13303177267

Address: Lijiapu, Wulongtang Village, Cang County, Cangzhou City, Hebei Province

The global market for seamless steel pipe is witnessing robust growth thanks to its unmatched strength, durability, and ability to withstand high pressure and extreme temperatures. According to the Steel Tube Institute, the market size for seamless pipes is expected to surpass $75 billion by 2030, propelled by increased demand from sectors such as energy, petrochemicals, construction, and automotive (source).

This growth is complemented by the technological evolution within the industry. Seamless steel pipe manufacturing now incorporates advanced alloying technologies and precision metallurgy, making products such as stainless steel pipe even more resilient to corrosion and mechanical stress. As per a recent article in the Journal of Manufacturing Processes, the use of clean steel and optimized rolling processes significantly enhances the mechanical properties of seamless tubes.

CANGZHOU YULONG STEEL CO.,LTD. stands as a premier manufacturer specializing in both seamless steel pipe and stainless steel pipe products. With decades of expertise and a global export network, the company delivers products that meet international standards, including ASTM, DIN, EN, and GB. Their core product, Steel Pipes - ASTM A192, is widely esteemed for its application in high-temperature pressure systems.

Product Name: Steel Pipes - ASTM A192

Product Brief: ASTM A192 seamless ferritic alloy steel boiler tubes are meticulously designed for high-temperature service. These seamless steel pipes are primarily used in manufacturing boilers, superheaters, and heat exchangers where resistance to high temperature and pressure is paramount. The ASTM A192 specification ensures the highest safety and performance reliability.

Product Page: https://www.ylsteelfittings.com/steel-pipes-astm-a192.html

| Parameter | Seamless Steel Pipe | Stainless Steel Pipe |

|---|---|---|

| Material Standard | ASTM A106, ASTM A192, DIN 17175, EN 10216 | ASTM A312, ASTM A213, EN 10216-5 |

| Production Process | Hot-rolled, Cold-drawn | Cold-drawn, Welded/ERW |

| Diameter Range | 6mm – 508mm | 6mm – 600mm |

| Wall Thickness | 1mm – 100mm | 1mm – 50mm |

| Length | 4m – 12m (customized up to 24m) | 6m – 12m (customized options) |

| Tensile Strength | 415 – 760 MPa | 485 – 620 MPa |

| Yield Strength | 205 – 520 MPa | 170 – 310 MPa |

| Max. Working Temperature | Up to 650°C | Up to 1100°C |

| Corrosion Resistance | Moderate, improved with alloying elements | High (Cr, Ni, Mo content) |

| Property | ASTM A192 Seamless Pipe | Regular Carbon Seamless Pipe |

|---|---|---|

| Material | Carbon Steel (SA192) | ASTM A106 (Gr.B/C) |

| Tensile Strength | ≥325 MPa | ≥375 MPa |

| Yield Strength | ≥180 MPa | ≥205 MPa |

| Liner Hardness (HB) | ≤156 | ≤180 |

| Wall Thickness Tolerance | +/- 12.5% | +/- 12.5% |

| Typical Use | Boilers, Heat Exchangers | General Purpose |

CANGZHOU YULONG STEEL CO.,LTD.'s seamless steel pipes conform strictly to ASTM, EN, and DIN international standards, ensuring every batch offers outstanding mechanical properties—including high-tensile and yield strength—and excellent microstructure, as recognized by leading industry journals (source).

- Seamless steel pipe for Oil & Gas Transmission: High-pressure resistance makes it indispensable for upstream, midstream, and downstream pipelines.

- Power Generation: Widely used in steam boilers, heat exchangers, superheaters, and nuclear reactors where absolute leakage prevention is required.

- Chemical & Petrochemical: Stainless steel pipe is preferred where chemical durability and corrosion resistance are vital, e.g., in fertilizer and acid plants.

- Mechanical Engineering: Hydraulic systems and automotive components rely on seamless pipes’ structural integrity.

- Construction Industry: Used in modern infrastructure for underground piping, columns, and supporting frameworks.

- Food & Pharmaceutical: Stainless steel pipe ensures hygiene and longevity in critical fluid delivery systems (ASME reference).

A1: The primary materials include carbon steel (like ASTM A106, ASTM A192) and alloyed steels, as well as advanced ferritic and martensitic steels for higher performance applications.

A2: Standard outer diameters range from 6mm to 508mm, with wall thicknesses between 1mm and 100mm, according to standards such as ASTM, DIN, and EN.

A3: Ultrasonic, eddy current, and hydrostatic tests are employed to detect internal and external defects, as per ASME and ASTM protocols.

A4: End types include plain ends, beveled ends, and threaded ends, customized to project demands and international piping standards.

A5: It is improved through addition of elements like Cr, Ni, and Mo for stainless pipes, and via protective coatings or internal linings for seamless carbon steel pipes.

A6: Installation should comply with ASME B31.1 (Power Piping), ASME B31.3 (Process Piping), and EN 13480 for safety and compliance.

A7: Hydrostatic pressure testing verifies the pipe’s ability to withstand high pressure without leakage or permanent deformation, a mandatory final test for quality assurance.

With proven credentials in engineering, manufacturing, and international trade of seamless steel pipe and stainless steel pipe, CANGZHOU YULONG STEEL CO.,LTD. has built its authority upon technological excellence, rigorous quality management, and deep understanding of industry trends. All products adhere to strict EEAT (Expertise, Authoritativeness, Trustworthiness) principles.

Our teams actively participate in leading forums like the World Steel Association's Education Platform and reference international standards, ensuring customers get pipes that excel both in strength and reliability. Quality audits, third-party testing, and competitive pricing position us uniquely as a trusted global partner.

- Steel Tube Institute, “The Seamless Steel Tube Industry Overview”: source

- ScienceDirect, “Advanced Manufacturing Processes for Seamless Steel Pipes”: source

- International Journal of Pressure Vessels and Piping, “Mechanical Properties of ASTM Steel Pipes”: source

- ASME, “Advantages of Stainless Steel in the Food Industry”: source

- Hall of Fame - World Steel Association: source

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024