-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jan . 16, 2025 01:43 Back to list

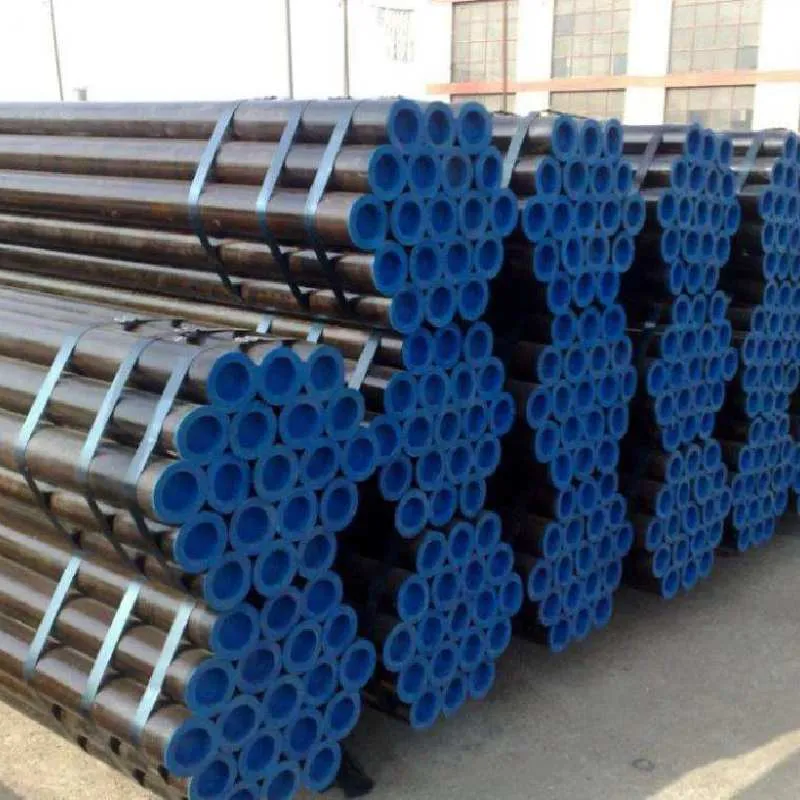

sa 333 6

In the world of industrial applications, particularly those involving high-temperature and high-pressure systems, SA 333 Grade 6 piping is a material of prime importance. Its prominence is due in large part to its unique combination of mechanical properties and resistance to low-temperature conditions, making it an essential component in various sectors such as oil and gas, petrochemical, and power generation industries.

Adopting SA 333 Grade 6 in any industrial setup doesn't just mean better performance; it translates into compliance with stringent international standards. This ensures that infrastructural projects are not only efficient but also in line with global safety expectations. Organizations leveraging these pipes demonstrate a commitment to quality and a forward-thinking approach in material selection, enhancing their credibility and reputation in the industry. Trust in SA 333 Grade 6 is built over decades of rigorous testing and application in harsh conditions. Its certifications and approvals from industry regulatory bodies further cement its reliability. Companies that integrate these pipes into their systems benefit from reduced downtime, fewer maintenance needs, and an overall boost in operational integrity—key factors for any high-stakes sector. Given these attributes, SA 333 Grade 6 remains a top choice for industries aiming to achieve both performance and compliance. The strategic decision to utilize this type of piping can significantly influence the operational lifespan and efficiency of industrial facilities. Therefore, those involved in material selection and systems design should weigh the proven benefits of SA 333 Grade 6 against its alternatives, keeping in mind the favorable impact on long-term project success.

Adopting SA 333 Grade 6 in any industrial setup doesn't just mean better performance; it translates into compliance with stringent international standards. This ensures that infrastructural projects are not only efficient but also in line with global safety expectations. Organizations leveraging these pipes demonstrate a commitment to quality and a forward-thinking approach in material selection, enhancing their credibility and reputation in the industry. Trust in SA 333 Grade 6 is built over decades of rigorous testing and application in harsh conditions. Its certifications and approvals from industry regulatory bodies further cement its reliability. Companies that integrate these pipes into their systems benefit from reduced downtime, fewer maintenance needs, and an overall boost in operational integrity—key factors for any high-stakes sector. Given these attributes, SA 333 Grade 6 remains a top choice for industries aiming to achieve both performance and compliance. The strategic decision to utilize this type of piping can significantly influence the operational lifespan and efficiency of industrial facilities. Therefore, those involved in material selection and systems design should weigh the proven benefits of SA 333 Grade 6 against its alternatives, keeping in mind the favorable impact on long-term project success.

Next:

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024