-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 18, 2024 03:46 Back to list

Understanding Socket Weld Pipe Fittings and Their Applications in Piping Systems

Socket Weld Pipe Fittings A Comprehensive Overview

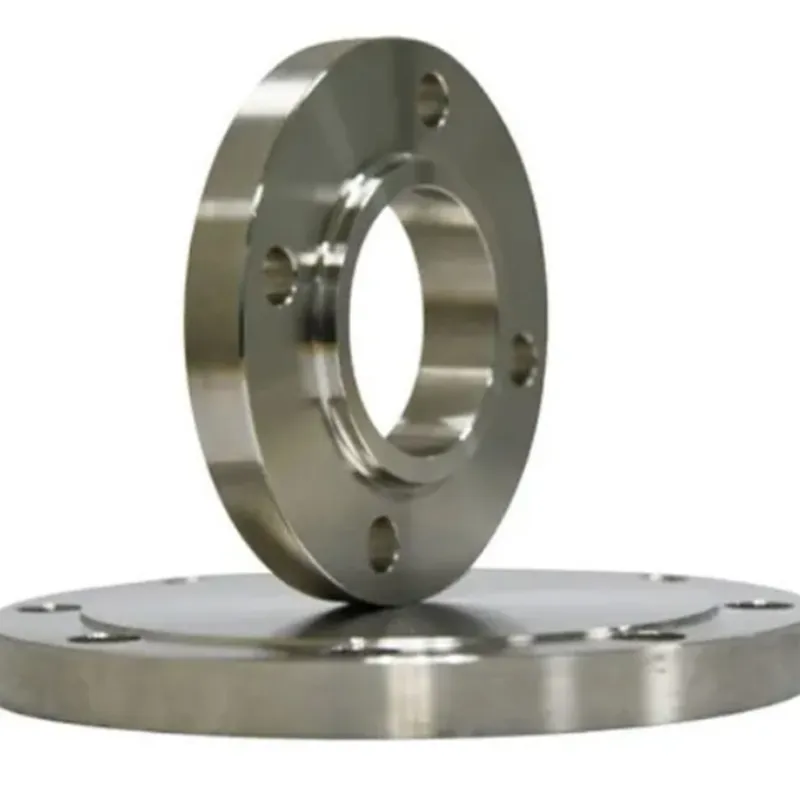

Socket weld pipe fittings are an essential component in piping systems, particularly in high-pressure and high-temperature applications. They are designed to provide a strong and reliable connection between pipes, ensuring the integrity of the system. The socket weld fitting consists of a fitting with a socket at one end, which allows the pipe to be inserted into it, making it ideal for various industrial applications.

One of the primary advantages of socket weld fittings is their ability to handle high pressures. The fittings are inserted into the socket and then welded, creating a strong join that can withstand significant forces. This makes them particularly suitable for use in sectors such as oil and gas, chemical processing, and power generation, where the integrity of the piping system is paramount.

Socket Weld Pipe Fittings A Comprehensive Overview

Installation of socket weld fittings involves several steps, which include cutting the pipe to the desired length, cleaning the surfaces to be welded, positioning the pipe in the fitting’s socket, and finally applying the appropriate welding technique. The most commonly used welding process for socket weld fittings is the TIG (Tungsten Inert Gas) method, which provides high-quality welds and minimizes the risk of defects.

socket weld pipe fitting

In addition to their strength and pressure-handling capabilities, socket weld fittings also provide a smooth flow path within the piping system. The design of the fitting minimizes turbulence and pressure drops, which can lead to improved efficiency in fluid transport. This is especially critical in applications where maintaining flow rates is essential for operational effectiveness.

Socket weld fittings come in various shapes and sizes, including elbows, tees, reducers, and caps. This variety allows for versatile configurations within piping systems, enabling engineers to design systems that meet specific operational requirements.

However, it is essential to consider certain limitations when using socket weld fittings. Their design is best suited for smaller diameter pipes, typically under 2 inches, as larger diameters may present challenges during installation and welding. Furthermore, proper training and adherence to safety standards are crucial during installation to prevent weld-related failures.

In conclusion, socket weld pipe fittings play a vital role in the construction of reliable and efficient piping systems. Their strength, versatility, and ability to withstand high pressures make them a popular choice across various industries. Understanding their applications, benefits, and installation requirements is essential for anyone involved in piping design and maintenance.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024