-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 19, 2024 21:43 Back to list

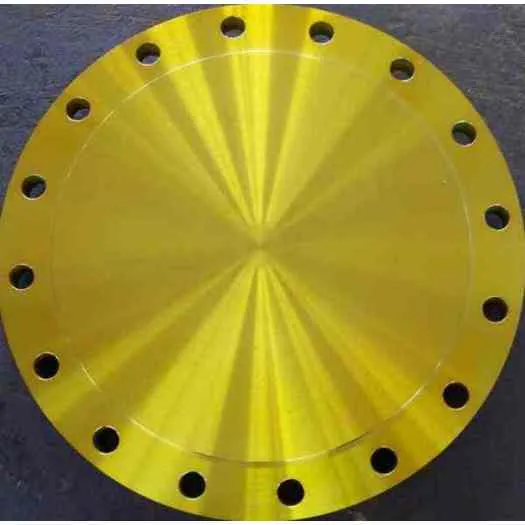

Stainless Steel Blind Flanges for High-Pressure and Temperature Applications

Understanding Stainless Steel Blind Flanges

Stainless steel blind flanges are crucial components within various piping systems, playing a vital role in sealing ends of piping systems and allowing for pressure containment. As part of the broader category of flanges, blind flanges are specifically designed to close off the ends of pipelines. Unlike other types of flanges that connect two sections of pipe, blind flanges have no central opening. This unique feature makes them significant in many industrial applications, from oil and gas to water treatment and chemical processing.

What is a Blind Flange?

A blind flange is essentially a flat piece of steel that provides a tight seal on the end of a pipeline. They are primarily manufactured from stainless steel due to their exceptional resistance to corrosion and rust, making them ideal for harsh environments. Stainless steel comes in various grades, the most common being 304 and 316. Grade 304 is known for its good corrosion resistance and formability, making it suitable for many applications, while Grade 316 offers enhanced resistance to chlorides and is used in more aggressive environments.

Applications of Stainless Steel Blind Flanges

Stainless steel blind flanges are widely used in numerous industries. In the oil and gas sector, they play a critical role in securing pipelines and preventing leakages. Chemical processing plants often use these flanges to safely transport hazardous materials, ensuring that no contaminants escape into the environment. Additionally, in water treatment facilities, blind flanges are essential for securing valves and outlets, helping maintain the integrity of the system.

Moreover, blind flanges are commonly found in HVAC systems, where they serve to close off sections of ductwork. They can also be used in construction projects to cap off pipes until they are needed, preventing debris from entering the system during construction.

Advantages of Stainless Steel Blind Flanges

stainless blind flange

One of the primary advantages of stainless steel blind flanges is their durability. The corrosion resistance inherent to stainless steel ensures a long life even in the most challenging conditions. This longevity is critical in preventing costly downtime and repairs associated with pipeline failures.

Moreover, stainless steel blind flanges can handle high pressure and temperature fluctuations, making them an ideal choice for high-pressure applications. Their robust design allows them to maintain integrity under stress, further reducing the risk of leaks.

Another significant benefit is the ease of installation. Blind flanges can be quickly and efficiently mounted, greatly reducing installation time compared to welded alternatives. This feature is particularly beneficial during system maintenance or upgrades, where minimizing downtime is crucial.

Considerations When Choosing Blind Flanges

When selecting stainless steel blind flanges, several important factors must be considered. The flange must match the pipe specifications in terms of size, pressure rating, and material. It’s also essential to consider the environment in which the flange will be used; factors such as temperature, pressure, and the nature of the fluid being transported should influence the choice of flange material.

Additionally, proper installation is key to ensuring the effectiveness of blind flanges. Ensuring that gaskets and bolts are sufficient and correctly installed can help in achieving a leak-proof seal, thereby enhancing overall system performance.

Conclusion

In conclusion, stainless steel blind flanges are indispensable components in various piping systems. Their durability, resistance to corrosion, and ability to handle high pressures make them suitable for a wide range of applications. By understanding the characteristics and advantages of these flanges, industries can ensure effective sealing solutions that contribute to the safe and efficient operation of their systems. Whether in chemical, oil, or water treatment sectors, the role of stainless steel blind flanges is undeniably crucial in maintaining system integrity and functionality.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024