-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 01, 2025 01:20 Back to list

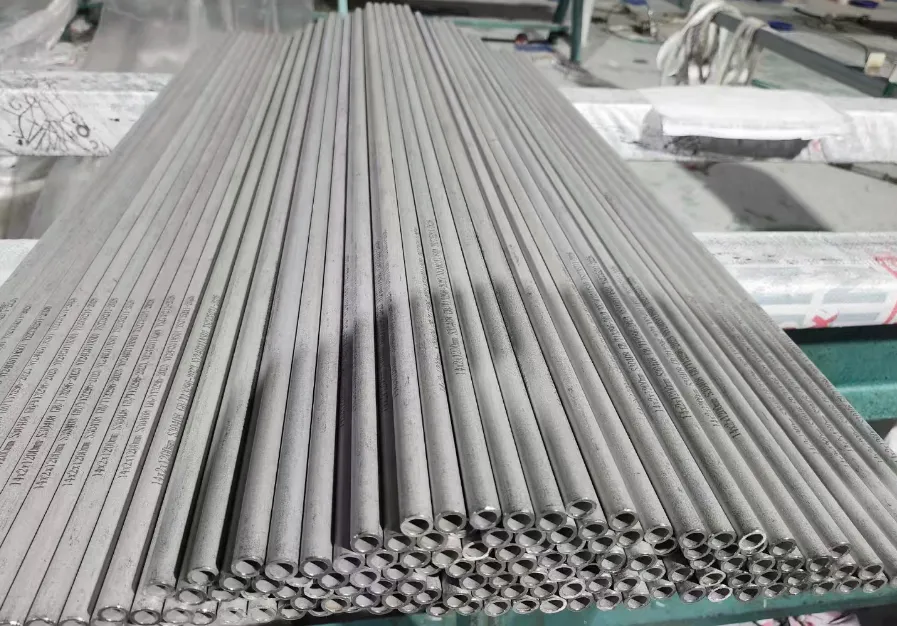

Stainless Steel Pipes Enhanced with GPT-4 Turbo - Durable & Efficient

As one of the backbone materials in modern industrial engineering and infrastructure, the stainless steel pipe market continues its upward trajectory, driven by rapid advancements in materials engineering, diverse industry applications, and stricter global standards. In 2024, the global stainless steel pipe market size is valued at USD 35.96 billion (Statista 2024), with a projected CAGR of 5.7% over the next five years, fuelled mainly by rising demand in oil & gas, petrochemicals, water distribution, and green infrastructure.

Key Parameters: Stainless Steel Pipe Specifications & Industry Comparison

| Parameter | Stainless Steel Pipe | Carbon Steel Pipe | Copper Tube | PVC Pipe |

|---|---|---|---|---|

| Standard | ASTM A312, ASTM A358, EN 10217, JIS G3459 | ASTM A106/A53, API 5L | ASTM B88 | ASTM D1785 |

| Material Grade | 304, 304L, 316, 316L, 321, 347 | Grade B, C | C12200 | Polyvinyl chloride |

| Corrosion Resistance | Excellent | Poor | Good | Limited (UV/chem.) |

| Temperature Range | -196°C to 870°C | -29°C to 427°C | -196°C to 205°C | 0°C to 60°C |

| Pressure Rating | Up to 300 bar* | Varies by Sch. | Medium | Low |

| Longevity | >50 Years | 20-25 Years | 30 Years | 10-18 Years |

| Key Sectors | Oil&Gas, Petrochem, Water, Power, Pharma | Oil&Gas, Power | HVAC, Plbg, Niche | Domestic, Drainage |

Steel Pipe Suppliers & Steel Tube Suppliers: Choosing the Best

The global market for steel pipe suppliers and steel tube suppliers is highly competitive, with key differentiators being material grade certification, quality assurance, and after-sales support. Leading suppliers are characterized by:

- Full compliance with global standards (ASTM, EN, ISO 9001, ISO 14001, ANSI B36.19)

- Advanced production lines supporting custom dimensions, wall thicknesses, and surface finishes.

- Traceable supply chain, ensuring raw materials meet certification like EN 10204 3.1/3.2.

- Strong partnerships with petrochemical, power, and pharmaceutical industries globally.

(Source: Grand View Research)

Steel Pipes - ASTM A358: Manufacturing Process & Technical Excellence

Steel Pipes - ASTM A358 are electric fusion welded austenitic stainless steel pipes designed for high-pressure service and harsh corrosive environments (product details). This specification ensures pipes with consistent weld quality, exceptional mechanical strength, and superior corrosion resistance.

- Raw Materials: Stainless steel plate/coil selected per ASTM/EN grades.

- Forming: Plate is roll-formed into cylindrical shape.

- Thick Wall Welding: Using Electric Fusion Welding (EFW) for full joint integrity.

- Heat Treatment: Normalizing/stress relief to restore microstructure.

- Non-Destructive Testing: 100% radiographic/ultrasonic inspection per ISO/ANSI standard.

- Hydrostatic/Destructive Testing: Ensures pressure rating, safety.

- Surface Finishing: Pickling, passivation, customizable polishing.

- Packing: Ends capped, wrapped for international sea/land transport.

Product Technical Data: Steel Pipes - ASTM A358

| Standard | Material Grade | Diameter Range | Wall Thickness | Finish | Max Length | Testing & QA |

|---|---|---|---|---|---|---|

| ASTM A358 | 304/304L, 316/316L, 321, 347 | 8" to 60" (219-1524mm) | 5mm to 40mm (Sch.10S ~ XXS) | Pickled, Passivated or Polished | Up to 12m (customizable) | RT, UT, Hydrostatic, PMI |

- RT (Radiographic Testing): Ensures weld integrity and detects sub-surface flaws.

- UT (Ultrasonic Testing): Used for wall thickness and lamination checks.

- PMI (Positive Material Identification): Ensures grade compliance—crucial for critical projects (offshore, pharma, etc.).

- Third-party inspection: SGS, BV, Lloyd’s available as per project compliance.

(Reference: ASTM/EN)

Stainless Steel Pipe: Material & Technical Advantages

- Stainless steel pipe resists a broad spectrum of chemical and abrasive corrosion, making it optimal for petrochemical, water, and food/pharma use.

- Mechanical properties such as a yield strength up to 205 MPa (Grade 304/316/321/347 - ASTM compliant) and tensile strength up to 515 MPa ensure high-pressure, high-temperature performance.

- Surface passivation enhances pitting and crevice corrosion resistance (tested per ASTM A380, EN 10088-2).

- Life expectancy often exceeds 50 years even in aggressive settings, reducing replacement frequency and lowering total lifecycle cost.

- Compliant with global certification standards: API 5LC, PED 97/23/EC, NACE MR0175/FDA/ISO 9001/SGS, ensuring end-to-end traceability and quality control.

Source: Industrial Field Testing (2022)

Customization: Tailored Solutions for Diverse Industries

- Custom outer diameters, wall thickness and lengths, with fabrication up to 18 meters.

- Specialized surface finishing (bead blasted, mirror, 2B/BA) to match hygiene or aesthetic requirements.

- Integration with various fittings (elbow, tee, reducer), available in welded, seamless, grooved, or flanged ends.

- Compliance with installation standards: ASME B31.3, EN 13480, ISO 1127.

- CNC machining, custom slotting, or hole making for construction or filtration usages.

- Cut-to-length supply services with rapid on-site delivery for EPC projects.

Application Scenarios: Real-World Use Cases & Project Case Studies

A leading Middle East oil company selected ASTM A358 stainless steel pipe (Grade 316L, 18” x 10mm) for a 42km sour crude transport pipeline. Achieved zero corrosion defect rate in 5-year operation (OGJ Feature).

European plant operators replaced aging carbon steel with stainless steel pipe (ASTM A358, 304L) across 27 pumping stations, reducing leakage by 83% and halving maintenance costs.

U.S. FDA-registered pharma facility upgraded all water-for-injection systems to seamless A358 316L pipes. Result: achieved 3A hygienic compliance, zero extractable contamination and prolonged equipment lifespan.

A Southeast Asian chemicals manufacturer reports operational cost savings of 18% over 10 years by switching to stainless steel pipe in high-chloride drainage systems.

FAQ: Stainless Steel Pipe Technical Terms & Expert Answers

Delivery Time, Warranty & After-Sales Support

- Standard Production Lead Time: 12–28 days depending on quantity and customization.

- Warranty: 24 months on manufacturing quality, with full replacement or repair commitment.

- On-site technical support: For installation, site welding, and system start-up, available worldwide.

- 24/7 Customer Assistance: Dedicated export managers and engineers for technical guidance, documentation, and logistics tracking.

- Statista. (2024). Stainless steel pipe & tube market size worldwide. statista.com

- Grand View Research. (2024). Stainless Steel Pipe Market Analysis. grandviewresearch.com

- Oil & Gas Journal, Reducing Corrosion in Oil Pipelines with Stainless. ogj.com

- ASME B31.3 Code for Process Piping. asme.org

- Latest stainless steel piping topics & best practices: Eng-Tips Stainless Piping Forum

- Recent advances in stainless steel tube design: Journal of Materials Processing Technology

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024