-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 26, 2024 03:20 Back to list

Stainless Steel Concentric Reducer for Efficient Fluid Flow Management in Piping Systems

Understanding Stainless Steel Concentric Reducers

In the realm of piping systems, particularly in industries such as oil and gas, water treatment, and manufacturing, the components used play a crucial role in determining efficiency, safety, and reliability. One such essential component is the stainless steel concentric reducer. This specialized fitting is designed to allow for a smooth transition between pipes of different diameters while maintaining a consistent centerline.

What is a Concentric Reducer?

A concentric reducer is a pipe fitting that connects two pipe sections of differing diameters. Unlike eccentric reducers, which have an off-centered design, concentric reducers have a symmetrical shape, allowing for a more uniform flow of fluids through the pipes. This design minimizes turbulence and helps maintain pressure within the pipeline, making them particularly useful in systems that transport liquids or gases.

The Role of Stainless Steel

Stainless steel is a favored material in many industrial applications due to its strength, durability, and resistance to corrosion. Concentric reducers made from stainless steel can withstand harsh environmental conditions, including exposure to chemicals, high temperatures, and varying pressures. This makes them ideal for use in industries such as chemical processing, food and beverage production, and petroleum refining.

One of the significant advantages of using stainless steel in pipe fittings is its ability to resist rust and corrosion. This characteristic is crucial in preventing leaks or failures in a piping system, which can lead to costly repairs and safety hazards. Moreover, stainless steel fittings are often designed to meet stringent industry standards, which further ensures their reliability and effectiveness.

Benefits of Stainless Steel Concentric Reducers

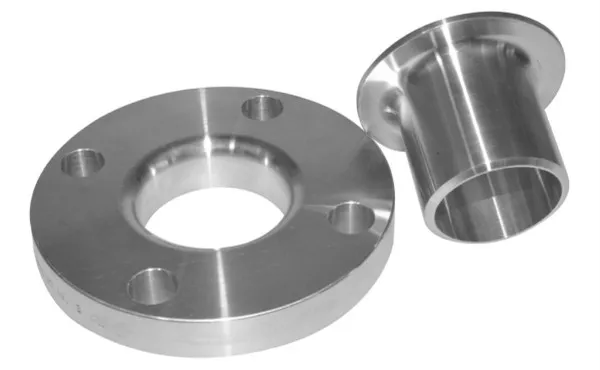

stainless steel concentric reducer

1. Smooth Flow Transition The concentric design allows for a gradual change in pipe diameter, which enhances fluid flow and reduces pressure drops. This efficiency is important in maintaining the overall performance of the system.

2. Durability Stainless steel is known for its durability. Concentric reducers made from this material are less likely to fail or deform under extreme pressures or temperatures, providing a long service life that can save costs on replacements.

3. Versatility These reducers are available in various sizes and specifications, making them suitable for different applications. Whether you need a reducer for a small-scale project or for a large infrastructure, you can typically find a stainless steel concentric reducer that meets your needs.

4. Ease of Installation Stainless steel concentric reducers often come with standardized fittings, making them easy to install in existing systems. Their compatibility with different types of piping systems enhances their usability across various industries.

5. Resistance to Corrosion As mentioned earlier, stainless steel resists corrosion, which is crucial in industries where chemical exposure is a concern. This property not only prolongs the life of the reducer but also ensures the integrity of the fluid being transported.

Conclusion

Stainless steel concentric reducers are vital components in many piping systems, offering a combination of durability, efficiency, and ease of installation. By facilitating a smooth transition between pipe sizes, they help to optimize fluid flow, minimize pressure losses, and maintain system stability. Whether used in industrial settings or large-scale infrastructure projects, these fittings are essential for ensuring the efficiency and safety of fluid transport systems. As industries continue to evolve and demand more reliable components, the role of stainless steel concentric reducers will remain critical in overcoming the challenges of modern piping systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024