-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Dec . 02, 2024 07:17 Back to list

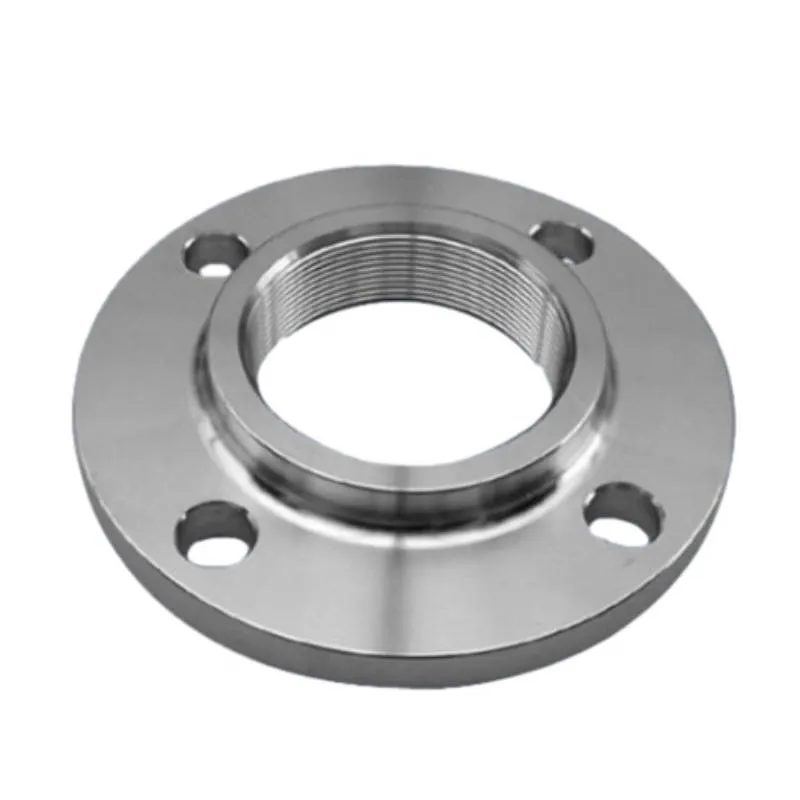

Leading Manufacturer of High-Quality Stainless Steel Flanges for Various Applications

Stainless Steel Flanges Manufacturer Ensuring Quality and Reliability

Stainless steel flanges are essential components used in various industries, including oil and gas, chemical processing, water treatment, and more. With their resistance to corrosion, high durability, and ability to maintain structural integrity under extreme temperatures, stainless steel flanges have become a preferred choice for manufacturers and end-users alike. As the demand for these critical components continues to rise, the role of stainless steel flanges manufacturers becomes increasingly important in ensuring quality and reliability in the supply chain.

Understanding Stainless Steel Flanges

Flanges are mechanical devices used to connect two parts of equipment or pipelines. They facilitate easy assembly and disassembly, making maintenance and repairs more manageable. Stainless steel flanges come in various types, including slip-on, weld neck, blind, and threaded, each designed to serve specific functions. The choice of flange type and material depends on the application and environmental conditions they will encounter.

Stainless steel itself is an alloy primarily composed of iron, carbon, and chromium. The addition of chromium significantly enhances the material's corrosion resistance, making it suitable for environments that involve acids, salts, and high humidity. Flanges made from stainless steel are not only durable but also versatile, accommodating a range of temperatures and pressures.

The Role of Manufacturers

A reliable stainless steel flanges manufacturer plays a pivotal role in the supply chain. They are responsible for sourcing high-quality raw materials, adhering to strict manufacturing standards, and delivering finished products that meet industry specifications. Here are several key aspects that highlight the importance of manufacturers in this market

1. Quality Control Manufacturers must implement rigorous quality control measures to ensure that every flange produced meets the required standards. This includes conducting material inspections, dimensional checks, and non-destructive testing to verify the integrity of the flanges. Companies that prioritize quality are more likely to build a reputation for reliability.

stainless steel flanges manufacturer

2. Customization and Versatility Different industries have varying requirements, and a good manufacturer will offer customization options to meet specific client needs. Whether it's custom sizes, unique pressure ratings, or special finishes, the ability to adapt products to suit different applications is essential for manufacturers looking to maintain a competitive edge.

3. Compliance with Standards The manufacturing and design of stainless steel flanges must comply with international standards such as ASTM, ASME, and ANSI. Adhering to these guidelines not only ensures safety and compatibility but also boosts customer confidence in the manufacturer's products.

4. Innovation and Technology The advancement of manufacturing technologies, including automation and precision machining, has enabled manufacturers to produce flanges with greater efficiency and accuracy. Incorporating innovative techniques allows for reduced production times while maintaining high-quality standards.

5. Sustainability Practices With increasing awareness of environmental issues, leading manufacturers are adopting sustainable practices in their operations. This includes recycling scrap material, minimizing waste, and utilizing eco-friendly production processes. Implementing green initiatives not only appeals to environmentally conscious clients but also contributes to a more sustainable industry.

Conclusion

As industries continue to evolve and grow, the demand for stainless steel flanges will likely increase. The role of stainless steel flanges manufacturers is crucial in meeting this demand while maintaining quality and reliability. By committing to stringent quality control, offering customization options, adhering to industry standards, embracing innovation, and promoting sustainability, manufacturers can position themselves as leaders in the market.

In summary, selecting a reputable stainless steel flanges manufacturer is essential for companies that rely on these components for their operations. The right manufacturer can make a significant difference in the performance and longevity of the systems that utilize these flanges, ultimately contributing to the overall success of an industry. Whether for new installations or replacements, investing in high-quality stainless steel flanges is a decision that will pay dividends in the long run.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024