-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 04, 2024 08:29 Back to list

stainless steel pipe 316l seamless

Understanding 316L Stainless Steel Seamless Pipes

316L stainless steel seamless pipes are widely recognized for their exceptional corrosion resistance and high durability, making them an essential material in various industries. The 316 designation indicates the type of stainless steel, which contains molybdenum and nickel, enhancing its resistance to corrosion, particularly in chloride environments. The L signifies a low carbon content, which reduces the risk of carbide precipitation during welding and elevates its resistance to intergranular corrosion.

One of the primary features of 316L stainless steel is its excellent performance in harsh chemicals. This quality makes it particularly useful in applications involving seawater, chemicals, and other corrosive environments. Industries such as petrochemical, pharmaceutical, food processing, and marine applications often rely on 316L pipes for their strength and longevity.

The seamless design of these pipes is another critical advantage. Unlike welded pipes, seamless pipes are manufactured without any joints or seams, ensuring uniform strength and increased resistance to pressure and temperature fluctuations. This continuous structure significantly reduces the risk of leaks and failures in high-pressure applications, enhancing safety and reliability.

stainless steel pipe 316l seamless

The manufacturing process of 316L seamless pipes involves forging and drawing the steel into the desired pipe shape. This method ensures a high density material with minimal imperfections, ideal for demanding applications. After production, the pipes undergo rigorous testing and inspection to ensure that they meet high standards and specifications.

Beyond their mechanical properties, 316L stainless steel pipes offer aesthetic appeal as well

. Their smooth, shiny finish not only contributes to a visually pleasing design but also makes them easier to clean and maintain. This characteristic is particularly important in industries where hygiene is paramount, such as in food and beverage processing.In terms of cost, 316L stainless steel pipes may be more expensive than their carbon or lower-grade stainless steel counterparts. However, the long-term savings from reduced maintenance, combined with their extended lifespan, often justify the initial investment.

In conclusion, 316L stainless steel seamless pipes are a superior choice for applications requiring durability, corrosion resistance, and safety. Their seamless construction, combined with excellent mechanical properties, makes them indispensable in various industrial sectors. As industries continue to evolve and demand robust materials, the significance of 316L pipes is likely to grow, making them an essential component in modern engineering and manufacturing solutions.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

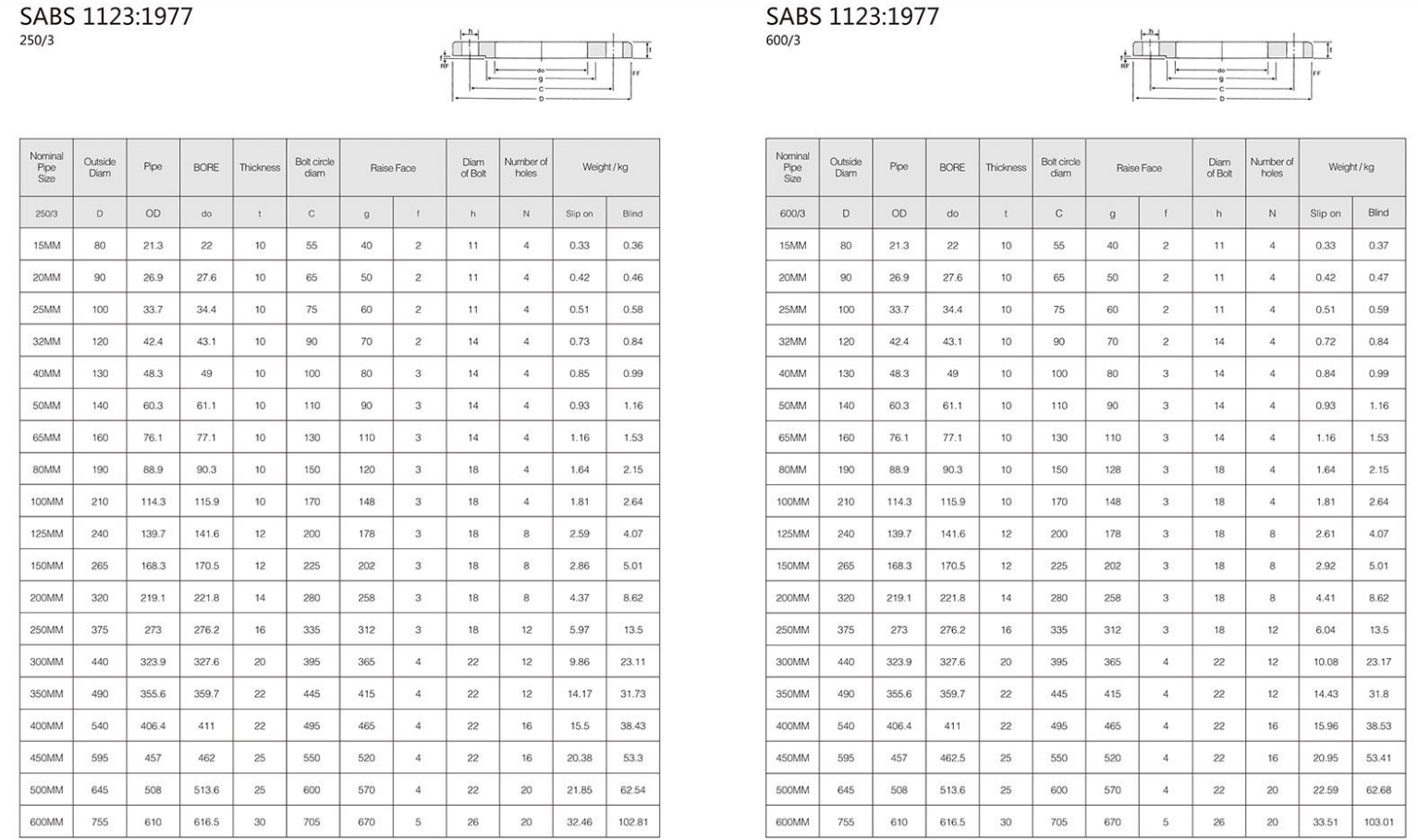

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024