-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Nov . 10, 2024 05:00 Back to list

Understanding Tapped Blind Flanges and Their Applications in Piping Systems

Understanding Tapped Blind Flanges An Integral Component in Piping Systems

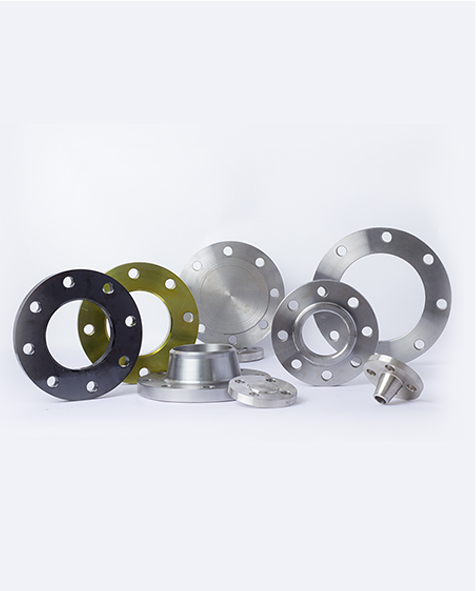

In the realm of industrial piping systems, various components play crucial roles in ensuring that systems operate efficiently and safely. One such component is the tapped blind flange. This specialized type of flange is vital in various applications where the need for pressure sealing and accessibility to the piping system is paramount. Let’s delve deeper into the definition, applications, benefits, and considerations associated with tapped blind flanges.

Definition of Tapped Blind Flange

A tapped blind flange is a type of flange that is designed to close off the end of a piping system but includes a threaded hole (or 'tap') that allows for future access. These flanges are typically manufactured from materials such as stainless steel, carbon steel, or alloy steel, ensuring durability and resistance to various environmental conditions. The blind aspect indicates that there is no opening through the flange to let fluid pass, while the tapped portion provides a threaded hole that can accommodate a bolt or other fastening fixtures for maintenance, pressure testing, or installation of additional equipment.

Key Applications

Tapped blind flanges find their applications in numerous settings, including but not limited to

1. Water and Wastewater Treatment They are often used in treatment plants where access points for sampling and pressure monitoring are necessary. 2. Oil and Gas Industries In this sector, tapped blind flanges can be essential for sealing off lines while allowing pressure tests or drainage operations without removing the entire flange.

3. Chemical Processing These flanges are used in chemical pipelines where processes might require periodic sampling or modifications without disrupting the flow.

4. HVAC Systems The ability to monitor pressure and service equipment with minimal disruption makes tapped blind flanges an important component in heating, ventilation, and air conditioning systems.

Benefits of Tapped Blind Flanges

Using tapped blind flanges offers several advantages

1. Ease of Access The primary benefit is the ability to gain access to the internal piping system without dismantling the entire assembly. This accessibility is critical for maintenance and periodic checks.

2. Safety By allowing pressure testing and sampling while retaining the integrity of the system, tapped blind flanges enhance workplace safety, minimizing leaks and failures.

tapped blind flange

3. Cost-Effective Maintenance Regular inspections and maintenance can be conducted efficiently, potentially reducing downtime and maintenance costs.

4. Customizability These flanges can be designed in various sizes and materials, catering to specific project requirements and ensuring compatibility with existing systems.

5. Versatility They can be utilized in various applications across different industries, making them a versatile choice in piping systems.

Considerations When Using Tapped Blind Flanges

While tapped blind flanges are advantageous, several factors should be considered during selection and installation

1. Material Selection Choosing the right material is crucial, particularly in aggressive environments. The flange material must withstand pressure, temperature, and any chemical exposure.

2. Pressure Ratings It is essential to select flanges that can handle the operational pressure of the system. Understanding the pressure class (ANSI, ASME, etc.) will ensure safety and reliability.

3. Threading Standards Proper threading standards must be followed for the tapped hole to ensure compatibility with the fittings or bolts used.

4. Installation Practices Proper installation is critical. It is advisable to follow manufacturer guidelines and industry standards to prevent leaks and ensure integrity.

5. Regular Inspection Even with built-in access points, regular inspections are essential to ensure that the flanges maintain their integrity over time.

Conclusion

Tapped blind flanges are indispensable in many industrial applications, offering a combination of accessibility and operational safety. As industries evolve and require more advanced piping solutions, understanding and utilizing components like tapped blind flanges will remain essential for efficiency and reliability. Their ability to balance safety, maintenance ease, and operational effectiveness makes them a critical component in modern piping systems. Whether in oil refineries, chemical plants, or HVAC systems, the tapped blind flange is an unsung hero, quietly ensuring that everything runs smoothly behind the scenes.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024