-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 23, 2024 16:22 Back to list

What is a buttweld pipe fitting?

What is a buttweld pipe fitting?

A buttweld pipe fitting is a weldable component used in piping systems for various purposes. These fittings are designed to be welded to pipes, providing a secure and durable connection. They serve several functions:

- Buttweld fittings, such as long radius elbows, enable changes in the direction of fluid flow within a pipeline.

- Concentric and eccentric reducers are types of buttweld fittings that allow for the reduction of pipe size, ensuring a smooth transition between pipes of different diameters.

- Tees are used to branch off from the main pipeline, facilitating the distribution of fluids to different directions or equipment.

- Buttweld fittings are available in various materials, including stainless steel and carbon steel, making them suitable for diverse applications

- Buttweld fittings are essential components in many industries, ensuring the integrity and reliability of piping systems. They are available in various sizes and types to meet the specific requirements of different applications.

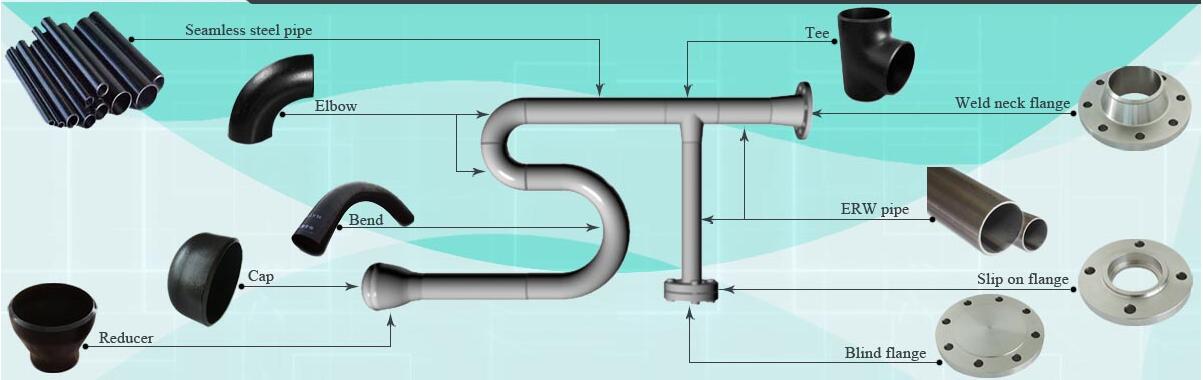

A buttweld fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. Forged Steel buttweld fittings are manufactured in accordance with ANSI / ASME B16.9.

Butt weld fittings are available as elbows, tees, caps, reducers and out lets (olets). These fittings are the most common type of welded pipe fittings and are specified by nominal pipe size and pipe schedule. Buttweld fittings use seamless or welded pipe as the starting material and are formed (through multiple processes) to get the shape of elbows, tees and reducers etc. Just as the pipe is sold from Schedule 10 to Schedule 160, butt weld pipe fittings are sold the same way. Welded butt weld fittings are more common in stainless steel due to cost advantage. SCH 10 fittings are also more common in stainless steel butt weld fittings.

Common material for butt weld fittings are A234 WPB (A & C also available), High Yield Carbon Steel, Stainless Steel 304 and 316 and Nickel Alloys.

Buttweld pipe fittings comprise of long radius elbow, concentric reducer, eccentric reducers and tees. They are an important part of industrial piping systems to change direction, branch off or to mechanically join equipment to the system. Buttweld fittings are sold in nominal pipe sizes with specified pipe schedule. BW fitting’s dimensions and tolerances are defined as per ASME standard B16.9.

Butt Weld fittings are also called Welded Pipe fittings. These welded fittings in carbon steel and stainless steel offer many advantages compared to threaded and socket weld fittings. The latter are only available up to 4-inch nominal size whereas butt weld fittings are available in sizes from ½” to 72”. Some of the benefits of Buttweld fittings are mentioned below.

Types of Butt Weld Pipe Fittings

Welded pipe fittings in carbon steel and stainless steel are the joining components that make possible the assembly of valves, pipes and equipment onto the piping system. Welded fittings compliment pipe flanges in any piping system and allows:

- Change direction of flow in a piping system

- Connect or joint pipes and equipment

- Provide branches, access and takeoffs for auxiliary equipment

A common example using welded pipe fitting is a pipe reduced by concentric reducer, welded to a weld neck flange and connected to equipment. The figure below represents a complete collection of butt welded pipe fittings.

LR 90 Elbow: Fittings that change direction in a piping system are called elbows. The directional change is given in degrees, such as 45 or 90. Long radius 90 degree elbow has the center line of elbow at 1.5 x NPS from elbow end. 3R elbow has center line at 3 x NPS from elbow end.

LR 45 Elbow: Long radius 45 degree elbow changes the direction by 45 degrees.

SR90 Elbow: Short Radius 90 degree elbow is the same as LR90, except for the measurement between end of elbow to the center line is 1 x NPS.

LR 180 degree Bend: Long Radius 180 degree return bend allows complete reversal of flow. The distance between end of elbow and the center line is 3 x NPS.

SR 180 degree Bend: Short Radius 180 degree return bend allows complete reversal of flow but in a much tighter turn. The distance between end of elbow and the center line is 1 x NPS.

Tee: Butt weld pipe Tee allows a 90 degree branch off from a running pipe. This allows for connecting auxiliary equipment to a pipe. A tee is welded on both sides to the pipe; leaving the branch open for branch off.

Reducing Tee: Butt weld reducing tee has a branch that is smaller than the main run. This allows for branching off to a smaller pipe or equipment from the main run.

Concentric Reducer: A concentric Reducer is also called welded concentric coupling. It allows for connecting a large pipe to a smaller pipe by means of welding. A concentric reducer allows a welded connection between two pipes with the same center line.

Eccentric Reducer: An eccentric reducer is also called welded eccentric coupling. It allows for welding a large pipe to a smaller pipe with an offset center line. The offset of the center line in an eccentric reducer is; Offset = 1/2 x (Largest ID - Smallest ID)

Weldolet: A weldolet, also called welding outlet, is a way of connecting a welded connection that is contoured at the bottom to match the contour of the pipe. So one end of the welding outlet is welded on the pipe, whereas the other end is open to be welded to any other pipe or equipment. A welding outlet requires mentioning the size of out let and the "Run Size" of pipe so the contour can match the contour of the pipe. The size of the welding outlet will always be smaller than run size such as 1/2" welding outlet can be used on pipe (run size) 1/2" and bigger.

Welded Stub End: Stub ends are used with lap joint flange to be welded onto the pipe.

ANSI/ASME B16.9 BUTT-WELDING FITTINGS Equal Tee/Reducing Tee

Butt Weld Pipe Fitting Bevel

All welded pipe fittings have beveled ends to allow for ease of welding. This bevel allows for full penetration weld in most cases.

Welding Bevel acc. to

- ASME B16.9, Factory-Made Wrought Steel Buttwelding Fittings

- ASME B16.28, Buttwelding Short Radius Elbows and Returns

- ANSI/ASME B16.25, Buttwelding Ends

- MSS SP-97, Socket Welding, Threaded, and Buttwelding Ends

There are two types of bevels:

Plain Bevel and Compound Bevel.

What is Butt Joint Welding?

A butt weld is a type of weld where the ‘butt end’ of the workpiece (pipes or tubes in our business) is welded to another in the same plane circumferentially. Butt welding is the most common type of joint that is used in piping systems. This type of welding is commonly used for pipe joints that do not require assembly or replacement, such as long-distance or underground pipelines.

A butt weld is a simple and versatile design of a welded joint. The butt weld is formed by simply inserting two pieces of metal next to each other and then welding along the weld seam. It is critical that in a butt weld, the surfaces of the workpieces are joined in the same plane and the weld metal remains within the places of the surfaces. The workpieces are therefore almost aligned and do not overlap, in contrast to overlap joints, for example.

Due to its simplicity, butt welding is the most widely used joining technique for a large number of applications in various industrial sectors. This fundamental welding technique has a number of different welding formations that are suitable for different welding thicknesses.

How a Butt Weld Fitting is Made?

A butt weld pipe fitting is made by the process of hot forming that includes bending and forming to shape. The starting material of butt weld fitting is a pipe that is cut to length, heated and molded into specific shapes by means of dyes. Heat treatment is also done to remove residual stresses and obtain desired mechanical properties. Read the link here to get more in depth detail of butt weld fitting manufacturing.

Benefits of Butt Weld Pipe Fittings

- Welded connection offers a more robust connection

- Continuous metal structure adds to the strength of the piping system

- Buttweld fittings with matching pipe schedules, offers seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting

- Option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

- Cost effective compared to their expensive threaded or socket weld counter parts

- Stainless Steel Welded Fittings are also available in SCH 10, allowing a more thinner wall option

- Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration

All butt weld fittings have beveled ends as per ASME B16.25 standard. This helps create full penetration weld without any extra preparation needed for the butt weld fitting.

Butt weld pipe fittings are most commonly available in carbon steel, stainless steel, nickel alloy, aluminum and high yield material. High yield butt weld carbon steel pipe fittings are available in A234-WPB, A234-WPC, A420-WPL6, Y-52, Y-60, Y-65, Y-70. All WPL6 pipe fittings are annealed and are NACE MR0157 and NACE MR0103 compatible.

Usage

Fittings are components that are used to connect, join, or adapt different parts of a system, such as pipes, tubes, or hoses. They serve multiple purposes, including:

- Connection: Fittings are used to connect sections of pipes, tubes, or hoses, ensuring a secure and leak-free joint.

- Directional Changes: They allow for changes in the direction of fluid or gas flow within a system, such as elbows or bends.

- Size Adaptation: Fittings can adapt pipes or tubes of different sizes, ensuring compatibility.

- Branching: They enable branching or splitting of fluid or gas flow into multiple directions, like tees or crosses.

- Valve and Control: Some fittings incorporate valves or controls to regulate or stop the flow as needed.

- Pressure Control: Fittings may include pressure-relief valves or regulators to control fluid or gas pressure.

- System Maintenance: Fittings with inspection ports or couplings facilitate system maintenance and testing.

- Connection to Equipment: Fittings allow pipes or hoses to connect to various equipment or appliances.

The choice of fittings depends on the specific requirements of the system, including factors like the type of fluid or gas, pressure, temperature, and the layout of the piping or tubing system. Different industries, such as plumbing, HVAC (Heating, Ventilation, and Air Conditioning), manufacturing, and construction, rely on fittings to ensure the proper functioning of their systems.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024