-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Sep . 06, 2024 00:50 Back to list

Types of Gaskets for Flanges - Comprehensive Guide

Types of Gaskets for Flanges

Gaskets play a crucial role in ensuring a tight seal between flanges in various applications, from plumbing to industrial processes. A gasket is a sealing component that prevents fluid or gas from leaking between two surfaces. When it comes to flanged joints, the choice of gasket material and type is of utmost importance, as it can directly impact the performance, reliability, and safety of the system.

1. Rubber Gaskets

Rubber gaskets are among the most commonly used types of gaskets for flanges. They are known for their flexibility and ability to conform to irregular surfaces, thus providing an excellent seal. Natural rubber, neoprene, and EPDM (ethylene propylene diene monomer) are popular materials in this category. These gaskets are often used in water and sewage applications due to their resistance to moisture and various chemicals.

2. Cork Gaskets

Cork gaskets are another popular option, particularly in low-pressure applications. They are made from cork granules combined with a binder and are typically used in automotive and HVAC applications. Cork gaskets can absorb fluids, making them resistance to swell, and they can provide an adequate seal under moderate conditions. However, their use is somewhat limited in high-temperature or high-pressure scenarios.

3. Graphite Gaskets

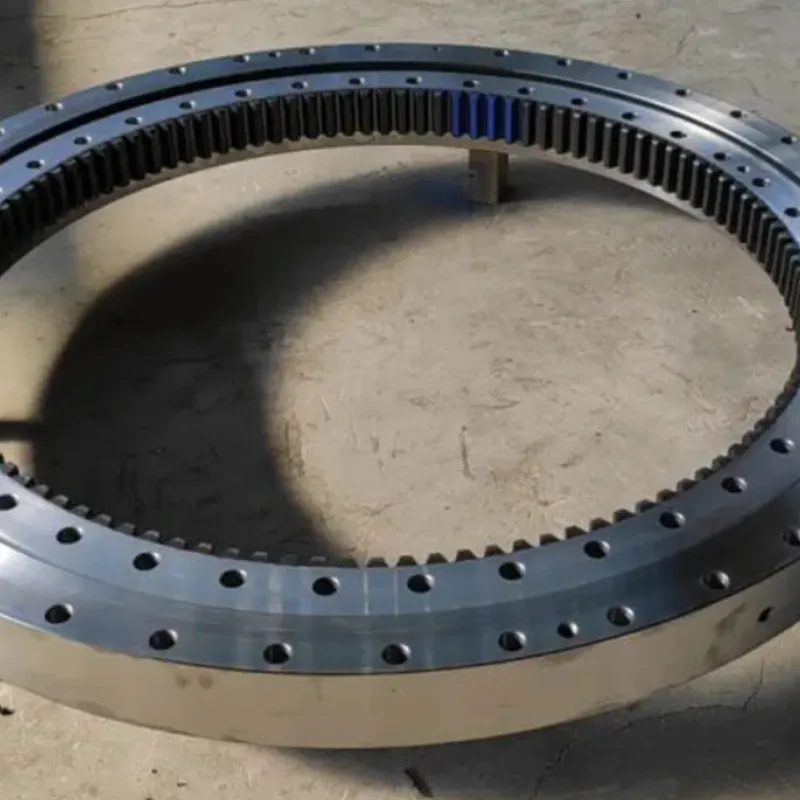

types of gaskets for flanges

Graphite gaskets are renowned for their outstanding thermal and chemical resistance. These gaskets are suitable for high-temperature applications, making them an excellent choice for steam systems and heat exchangers. Graphite gaskets can withstand extreme conditions but require proper installation to prevent issues such as nipping and cracking.

4. Metal Gaskets

Metal gaskets, such as spiral wound or ring-type joint gaskets, are used in high-pressure and high-temperature applications. These gaskets are made from materials like stainless steel and are designed to withstand harsh environments. Spiral wound gaskets, in particular, consist of alternating layers of metal and filler material, providing excellent sealing properties while allowing flexibility. They are widely used in the oil and gas industry, as well as chemical processing.

5. PTFE Gaskets

Polytetrafluoroethylene (PTFE) gaskets are known for their high chemical resistance and non-stick properties. They are ideal for use in chemically aggressive environments and can handle a wide temperature range. PTFE gaskets are commonly used in the pharmaceutical and food processing industries due to their hygienic properties. Their inherent slickness, however, can pose challenges in sealing under extreme pressure, requiring careful consideration during installation.

Conclusion

Selecting the appropriate gasket for flanges is essential for ensuring a secure, leak-free connection. The choice of gasket material and type will depend on the specific requirements of the application, including temperature, pressure, and the types of fluids involved. Understanding the various types of gaskets and their properties can help engineers and maintenance personnel make informed decisions and maintain the integrity of their systems effectively. Whether opting for rubber, cork, graphite, metal, or PTFE gaskets, ensuring compatibility with the application is key to achieving optimal performance and reliability.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024