-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 13, 2024 07:36 Back to list

Understanding the Differences Between Forged Socket Welding and Threaded Fittings in piping applications

Forged Fittings Socket Welding and Threaded Connections

Forged fittings play a crucial role in various piping systems across industries such as oil and gas, water treatment, and chemical manufacturing. Among the different types of fittings available, socket welding and threaded fittings are widely used due to their reliability and ease of installation. This article explores these two types of forged fittings, their applications, advantages, and considerations in industrial settings.

Understanding Forged Fittings

Forged fittings are fabricated by forging, a process that involves shaping metal through deformation, typically using compressive forces. This method enhances the material's strength and durability, making forged fittings preferable over cast fittings in high-pressure and high-temperature applications. They are available in various shapes and sizes, including elbows, tees, reducers, and caps, catering to a broad spectrum of piping requirements.

Socket Welding Fittings

Socket welding is a type of connection that facilitates the joining of two pipes or fittings where one pipe is inserted into a cup-like fitting (the socket). This method is particularly advantageous for smaller diameters (typically up to 2 inches) and is commonly used in high-pressure and high-temperature applications. The process involves inserting the pipe into the fitting and then welding around the joint.

One of the primary advantages of socket welding fittings is the creation of a strong, leak-proof joint. The welding process eliminates the possibility of leaks, which is crucial in applications where fluids or gases need to be contained securely. Additionally, socket welding provides a smooth internal bore that promotes better flow characteristics and minimizes turbulence.

forged fittings socket welding and threaded

However, it is essential to note that socket welding may not be suitable for applications requiring large fitting sizes, as the heat affected by the welding process can lead to thermal expansion, potentially causing joint failure if not properly managed.

Threaded Fittings

Threaded fittings are another popular type of forged fitting, particularly used in applications where disassembly is necessary. These fittings feature internal or external threads that allow for the easy connection of pipes without the need for welding. The assembly is done by screwing the fittings together, providing a strong mechanical joint.

The key advantages of threaded fittings include their ease of installation and the ability to disassemble without damaging the pipes or fittings. This feature makes them ideal for maintenance-focused systems where regular inspection or replacement of components is necessary. Moreover, threaded fittings can be used in both low-pressure and high-pressure applications, although they are generally more suitable for lower-pressure systems compared to socket welding.

Despite their advantages, threaded connections can pose some risks, particularly concerning leaks. The threaded joint may loosen over time due to vibration or thermal cycling, leading to potential leakage. To mitigate this risk, proper sealing compounds and thread sealants are often used during installation.

Conclusion

In conclusion, both socket welding and threaded forged fittings offer unique benefits that cater to different operational needs in various industries. Socket welding fittings provide robust, leak-proof joints suitable for high-pressure applications, while threaded fittings excel in ease of installation and disassembly. The choice between these fitting types ultimately depends on the specific requirements of the piping system, including pressure ratings, temperature considerations, and maintenance practices. Understanding the characteristics and appropriate applications of each type can lead to improved performance and longevity of piping systems, enhancing overall operational efficiency.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

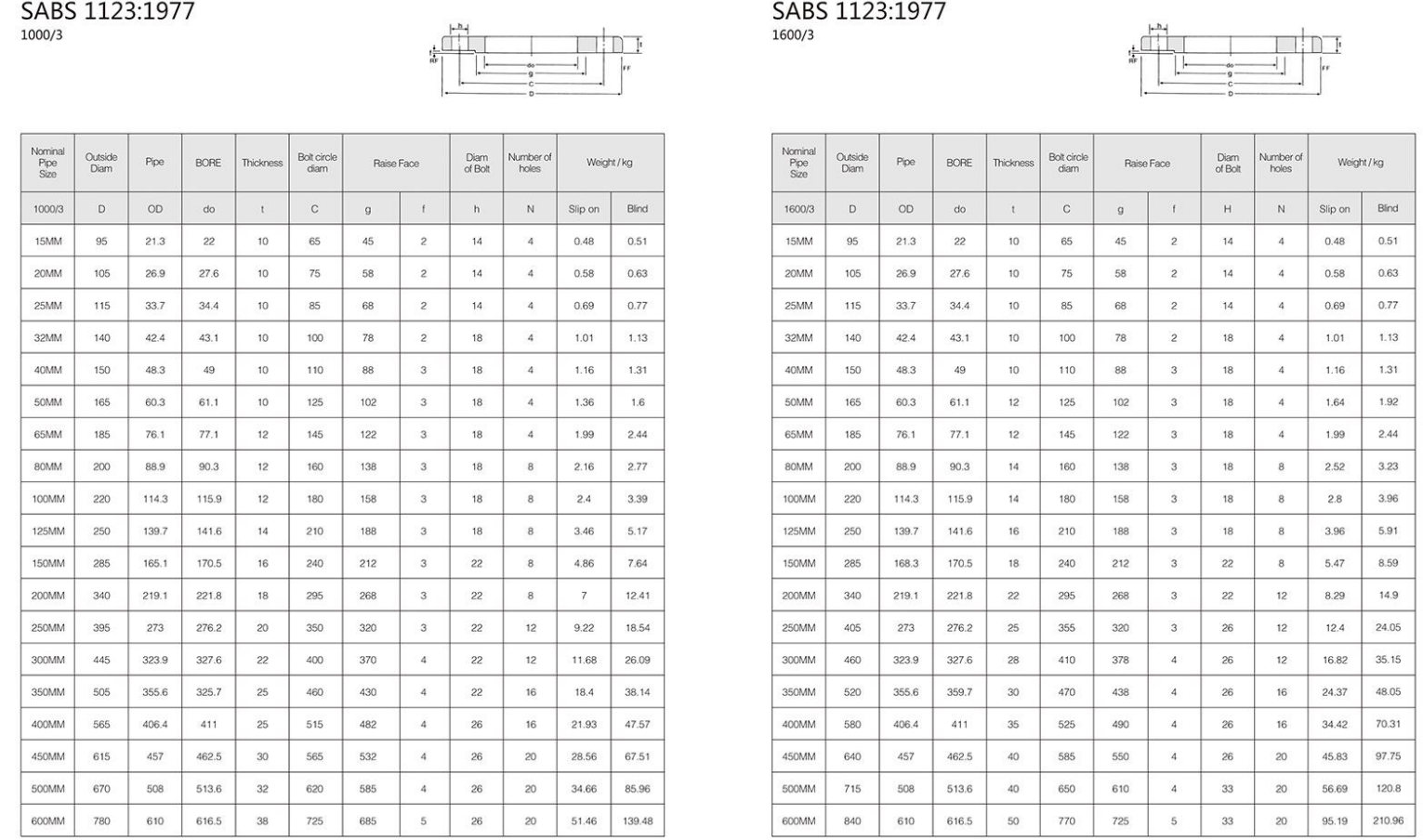

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024