-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jul . 27, 2024 01:41 Back to list

Understanding the Specifications and Applications of a 150mm Flange in Engineering Projects

Understanding the Importance of a 150mm Flange Design, Applications, and Benefits

When it comes to piping systems and the construction of various mechanical structures, the term flange frequently emerges. Among the different types of flanges used in industry, the 150mm flange holds significant importance due to its standardization and versatile applications. This article will explore the design aspects, uses, and advantages of utilizing a 150mm flange in contemporary engineering.

Design Aspects of a 150mm Flange

A 150mm flange describes a circular plate with a 150mm nominal diameter, typically used to connect two pieces of piping or equipment. Designed in accordance with international standards, 150mm flanges are available in various types, including weld neck, slip-on, blind, and threaded flanges. Each design serves a specific purpose and is selected based on factors such as the type of fluid being transported, the pressure and temperature conditions, and the environment in which the system operates.

The flange surface finishes are also crucial; they can be smooth or rough depending on the sealing requirements and the specific application. Additionally, 150mm flanges are often made from materials like stainless steel, carbon steel, or plastic, each chosen for its resistance to corrosion, temperature fluctuations, and mechanical stresses.

Applications of 150mm Flanges

The applications of 150mm flanges are vast and varied, spanning across multiple industries. One of the most common uses is in the oil and gas sector, where these flanges provide robust connections that can withstand high pressures and harsh environments. Similarly, in water treatment facilities, 150mm flanges link sections of pipelines, ensuring the efficient transport of water while maintaining a secure and tight seal.

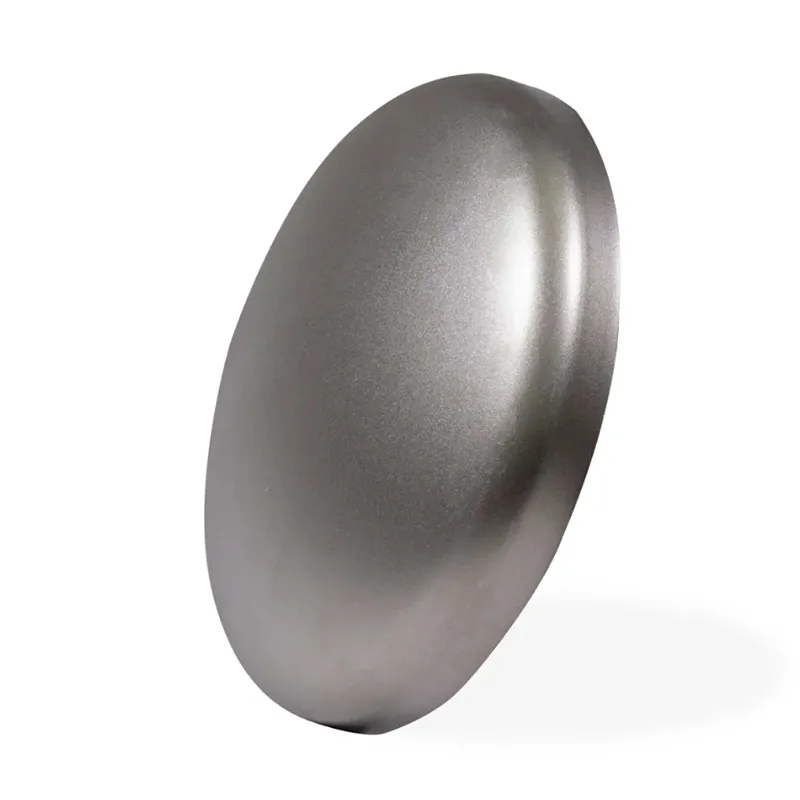

150mm flange

Moreover, in the HVAC (Heating, Ventilation, and Air Conditioning) industry, 150mm flanges are utilized to connect ductwork and enable smooth airflow management. In food and beverage manufacturing, these flanges are vital for sanitary construction processes, ensuring that equipment can be easily cleaned and maintained.

Benefits of Using a 150mm Flange

Utilizing a 150mm flange offers several advantages that contribute to the overall efficiency and reliability of piping systems. Firstly, standardization is one of the core benefits. The 150mm sizing conforms to widely accepted industry standards, meaning that components from different manufacturers can be interoperably used without extensive modification. This interoperability streamlines inventory management and reduces downtime during maintenance.

Secondly, the robustness of a 150mm flange contributes to enhanced safety. Its sturdy construction and ability to handle high-pressure applications reduce the risk of failures, leaks, and catastrophic failures, protecting both the workforce and the environment.

Additionally, the ease of installation and maintenance is a significant advantage. Flanges allow for quick assembly and disassembly of pipeline sections, making repairs and inspections straightforward. This is particularly beneficial in industries that require frequent maintenance or updates to the system.

Conclusion

In summary, the 150mm flange is a critical component in various engineering applications. With its well-defined design, extensive applications, and numerous benefits, it facilitates efficient and safe connections within piping and machinery systems. As industries continue to evolve and innovate, the significance of the 150mm flange will remain a cornerstone in the construction and maintenance of reliable infrastructure. Understanding its features and use cases equips professionals with the knowledge necessary to enhance system efficiency and safety in their respective fields.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024