-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 14, 2024 06:44 Back to list

Understanding the Specifications and Applications of PN10 DIN 2576 Flanges in Industrial Systems

Understanding Flange DIN 2576 PN10 Specifications and Applications

Flanges are integral components in piping systems, used for connecting pipes, valves, pumps, and other equipment. Among the various types of flanges, the DIN 2576 PN10 flanges stand out due to their specific design and pressure rating, making them suitable for a variety of industrial applications. This article delves into the specifications, advantages, and uses of DIN 2576 PN10 flanges.

What is DIN 2576 PN10?

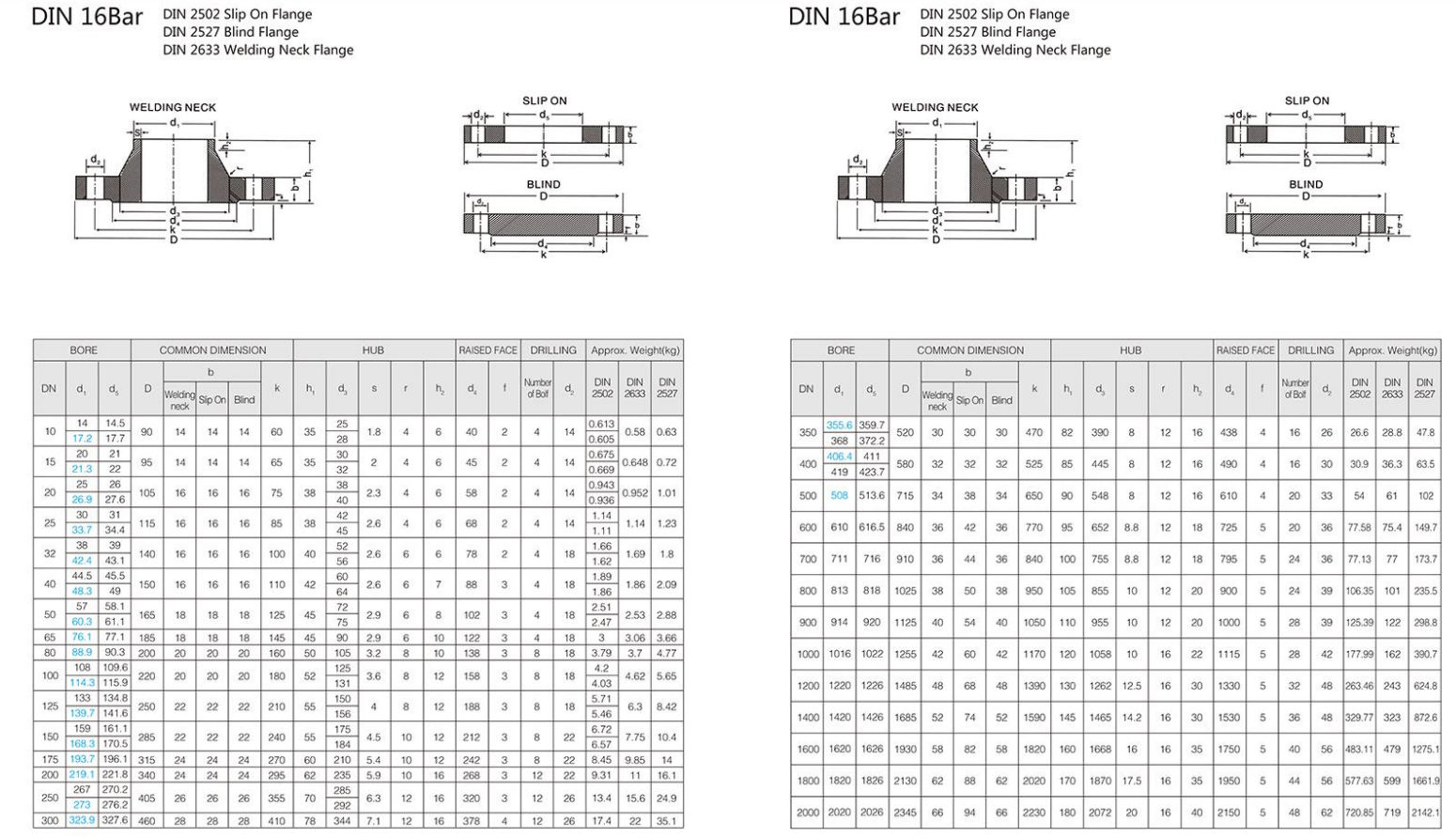

DIN 2576 is a standard that describes the dimensions and specifications for a series of flat flanges with specific pressure ratings. DIN stands for the Deutsches Institut für Normung (German Institute for Standardization), which has laid down these standards to ensure quality and compatibility in the manufacturing of industrial components. The PN designation refers to the nominal pressure of the flange, with PN10 indicating a pressure rating of 10 bar (approximately 145 psi). This indicates that the flange can safely support internal pressures up to this limit, making it suitable for various fluid transport scenarios.

Key Specifications

The DIN 2576 PN10 flanges are characterized by their flat face designs, which allow for easy sealing and installation

. The key specifications include- Material These flanges are typically constructed from carbon steel, stainless steel, or other alloys, depending on the application requirements, including resistance to corrosion and temperature. - Dimensions The dimensions of DIN 2576 PN10 flanges are standardized, including bolt holes that facilitate their attachment to other components. Common sizes range from DN 10 (10 mm) to DN 1000 (1000 mm) in diameter. - Sealing The flat face design allows for the use of gaskets, providing effective sealing capabilities to prevent leaks in a piping system. - Temperature Range While the standard specifies pressure ratings, the temperature tolerance can vary based on the material used, typically ranging from -20°C to 150°C for carbon steel flanges in non-corrosive environments.

Advantages of DIN 2576 PN10 Flanges

1. Standardization Being manufactured according to DIN standards ensures that these flanges are interchangeable with other components that meet the same specifications. This facilitates maintenance and repairs in various industrial settings.

flange din 2576 pn10

2. Versatility DIN 2576 PN10 flanges are used across different industries, including water treatment, chemical processing, and HVAC systems. Their ability to handle various types of fluids makes them a versatile choice for engineers and designers.

3. Reliability With their robust construction and design, these flanges minimize the risk of leaks and failures, enhancing the overall reliability of the piping system.

4. Cost-Effectiveness The straightforward design and widespread availability of DIN 2576 PN10 flanges contribute to lower costs in both procurement and installation.

Applications

The applications of DIN 2576 PN10 flanges are vast. They are commonly used in

- Water and Wastewater Treatment Due to their resistance to corrosion and ability to withstand moderate pressure, these flanges are ideal for systems dealing with drinking water and wastewater. - Chemical Industries The materials used in the construction of these flanges can be selected based on the chemicals involved, making them suitable for various chemical processes and reactions. - HVAC Systems They play a vital role in air conditioning and heating systems, ensuring sealed connections that can handle varying pressures and temperatures.

Conclusion

In summary, DIN 2576 PN10 flanges are essential components in modern piping systems. Their adherence to stringent standards, coupled with their durability and versatility, make them a preferred choice in various applications across industries. By understanding the specific features and benefits of these flanges, engineers and designers can ensure the efficiency and reliability of their systems, thereby enhancing operational success.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024