-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Aug . 13, 2024 13:56 Back to list

Understanding the Uses and Specifications of Blind Flanges in Piping Systems and Applications

Understanding Blind Flanges A Comprehensive Overview

Blind flanges are essential components in piping systems, designed to close off the end of a pipe or vessel. Their importance cannot be overstated, as they play a critical role in maintaining the integrity and safety of pressure systems, as well as aiding in the organization and management of fluid flow in various applications. This article explores the functionality, benefits, and design considerations of blind flanges.

What is a Blind Flange?

A blind flange is a type of flange that does not have a hole in the center. Unlike standard flanges, which allow for connections between two or more sections of pipe, a blind flange is used specifically to seal the ends of pipes or to isolate certain sections of a piping system. This is particularly useful in situations where a particular section does not require fluid flow, such as during maintenance or when a temporary blockage is necessary.

Applications of Blind Flanges

Blind flanges are commonly utilized across a variety of industries, including oil and gas, water treatment, chemical processing, and power generation. In these sectors, they are often employed to

1. Close Off Pipes When a section of a pipeline is taken offline for maintenance, blind flanges can be used to seal off the ends to prevent leaks and enhance safety.

2. Isolate Equipment Blind flanges are instrumental in isolating equipment in a plant, allowing for safe inspections, cleaning, and repairs without affecting the entire system.

3. Test Pressure In pressure testing scenarios, blind flanges are used to cover the ends of pipes or vessels, helping maintain the necessary pressure for testing structural and operational integrity.

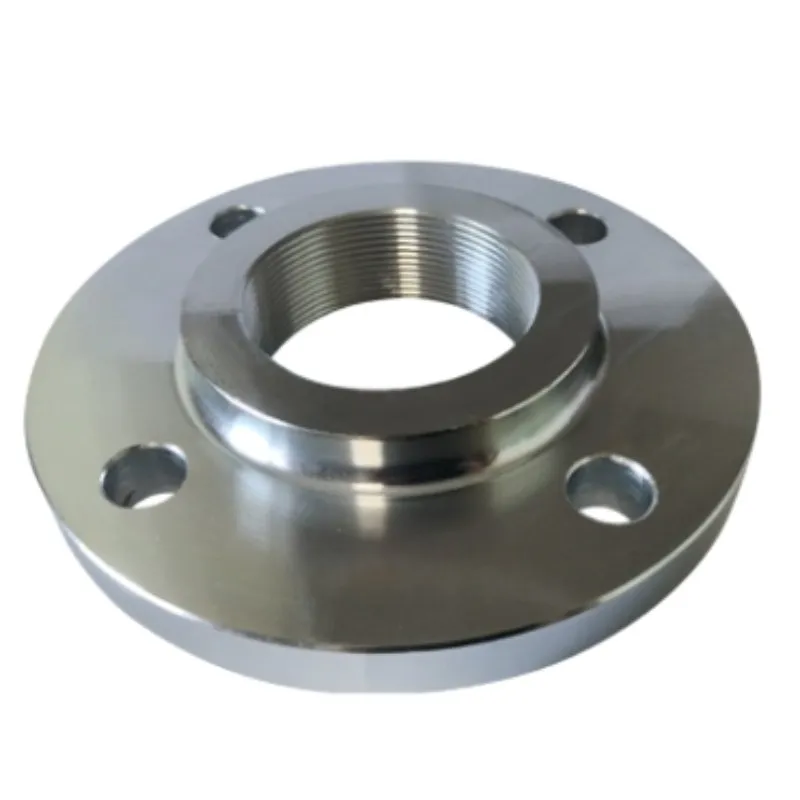

blind flange 4

4. Modify Flow Direction Blind flanges can also assist in re-routing fluid flow by blocking off certain sections while allowing others to remain in operation.

Design Considerations

When selecting a blind flange for a specific application, several design factors must be taken into account

1. Material Selection Blind flanges can be manufactured from various materials including stainless steel, carbon steel, and alloy materials. The choice of material often depends on the environmental conditions, the type of fluid in the system, and temperature and pressure ratings.

2. Pressure Rating Blind flanges are categorized by pressure ratings, including schedules 40, 80, and other classifications. It's crucial to choose a flange that can withstand the operational pressures of the system.

3. Size and Dimensions The size of the blind flange must match that of the pipe it is sealing. Measurements such as diameter, thickness, and bolt hole spacing are key to ensuring a proper fit.

4. Standards and Specifications Complying with industry standards (such as ANSI, ASME, DIN, etc.) is vital to ensure that the blind flanges can withstand the required stresses and to ensure compatibility with existing systems.

Conclusion

In summary, blind flanges serve a fundamental function in the design and operation of piping systems. Their ability to securely close off pipes and isolate segments of the system enhances safety and facilitates maintenance operations. By understanding the various applications, design considerations, and material selections available, engineers and industry professionals can make more informed decisions in their projects. Whether used in complex industrial systems or simple plumbing applications, blind flanges are a versatile and reliable solution in fluid management and engineering.

Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024