-

Cangzhou Yulong Steel Co., Ltd.

-

Phone:

+86 13303177267 -

Email:

admin@ylsteelfittings.com

- English

- Arabic

- Italian

- Spanish

- Portuguese

- German

- kazakh

- Persian

- Greek

- French

- Russian

- Polish

- Thai

- Indonesian

- Vietnamese

- Zulu

- Korean

- Uzbek

- Hindi

- Serbian

- Malay

- Ukrainian

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Miao

- Hungarian

- Icelandic

- igbo

- irish

- Japanese

- Javanese

- Kannada

- Khmer

- Rwandese

- Afrikaans

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Dutch

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Turkish

- Turkmen

- Urdu

- Uighur

- Welsh

- Bantu

- Yiddish

- Yoruba

Jun . 20, 2024 03:14 Back to list

Valve with flanged connection type.

Understanding Flange Type Valves A Comprehensive Overview

Flange type valves, an integral part of various industrial piping systems, play a crucial role in controlling and directing fluid flow. These valves are named after their distinctive feature - the flanges, which are integral components that facilitate their installation and connection to pipes or other equipment.

A flange is a protruding ring or rim used for strength or as an attachment point. In the context of valves, the flange type design allows for easy removal and replacement without disrupting the entire pipeline system. This makes them particularly advantageous in industries where regular maintenance or repair is necessary, such as oil and gas, chemical processing, and water treatment plants.

There are several types of flange type valves, each designed to cater to specific operational requirements and conditions. The most common varieties include Gate Valves, Globe Valves, Ball Valves, and Butterfly Valves.

Gate valves, for instance, are primarily used for isolation purposes, providing a full flow path when fully open and a complete shut-off when closed. Their wedge-shaped disc slides up and down between the valve body's seating surfaces. On the other hand, globe valves are ideal for regulating flow, as they use a plug that moves linearly to control fluid passage.

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation flange type valve. Lastly, butterfly valves, with their disc-shaped closure member, are lightweight and cost-effective, making them suitable for low-pressure applications.

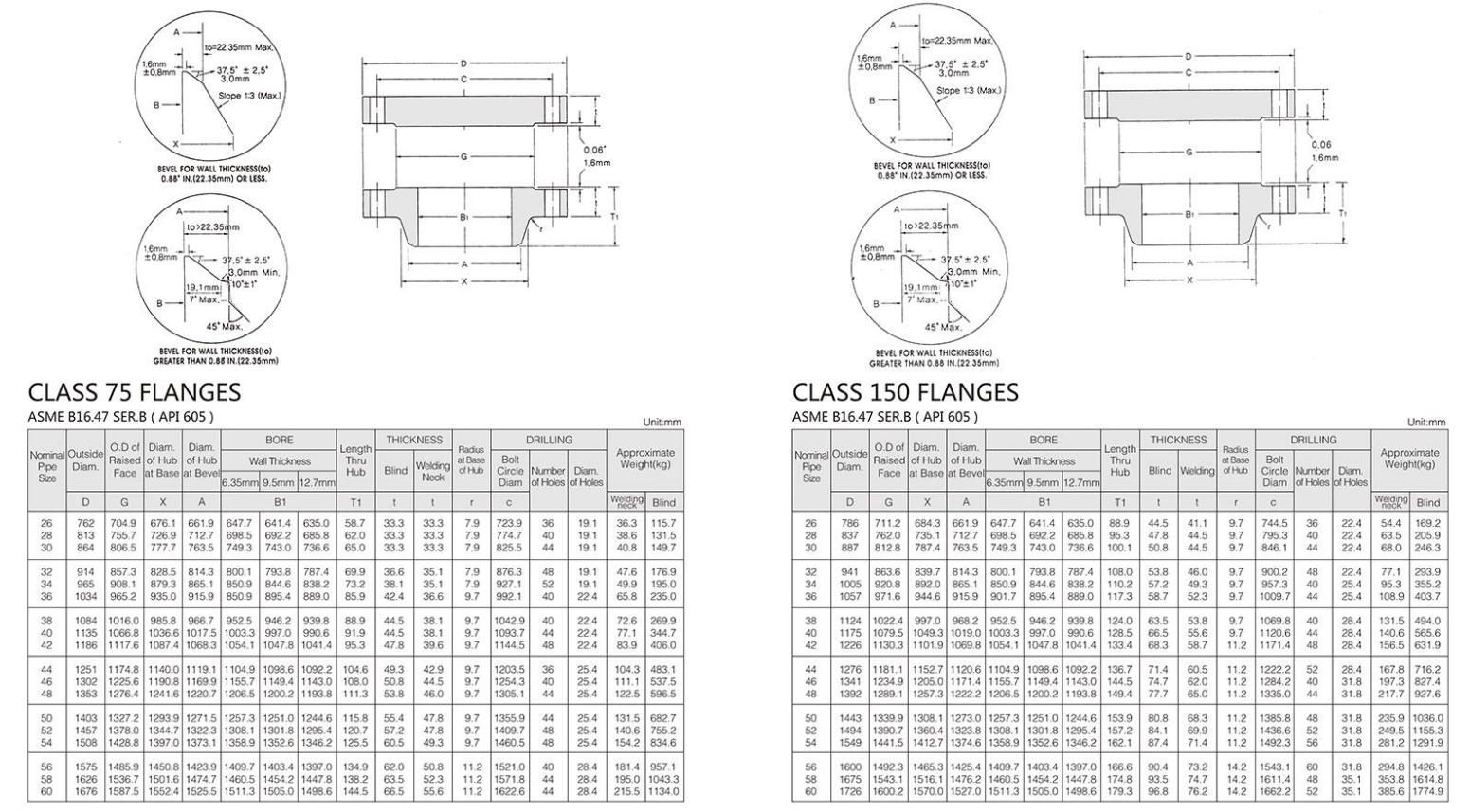

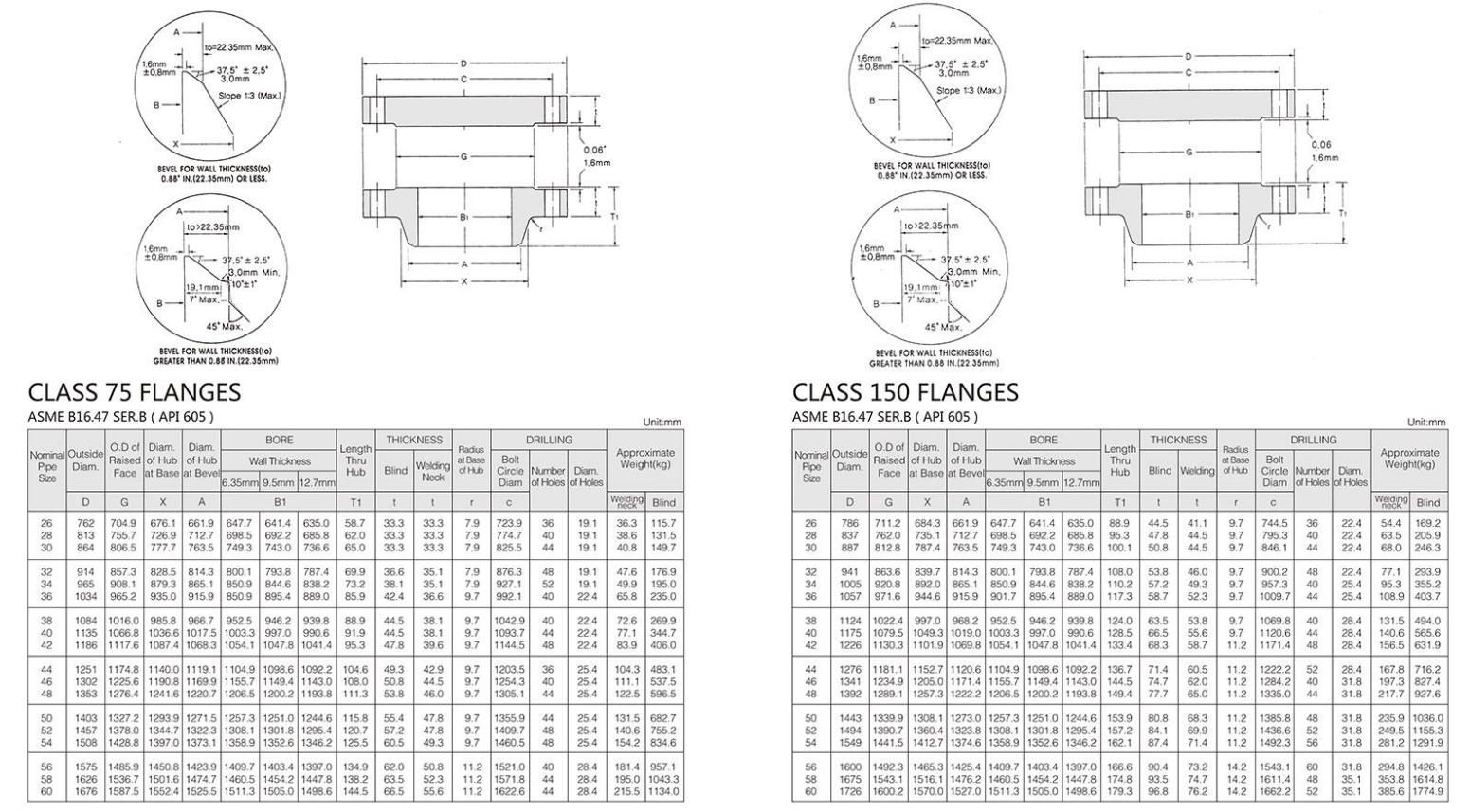

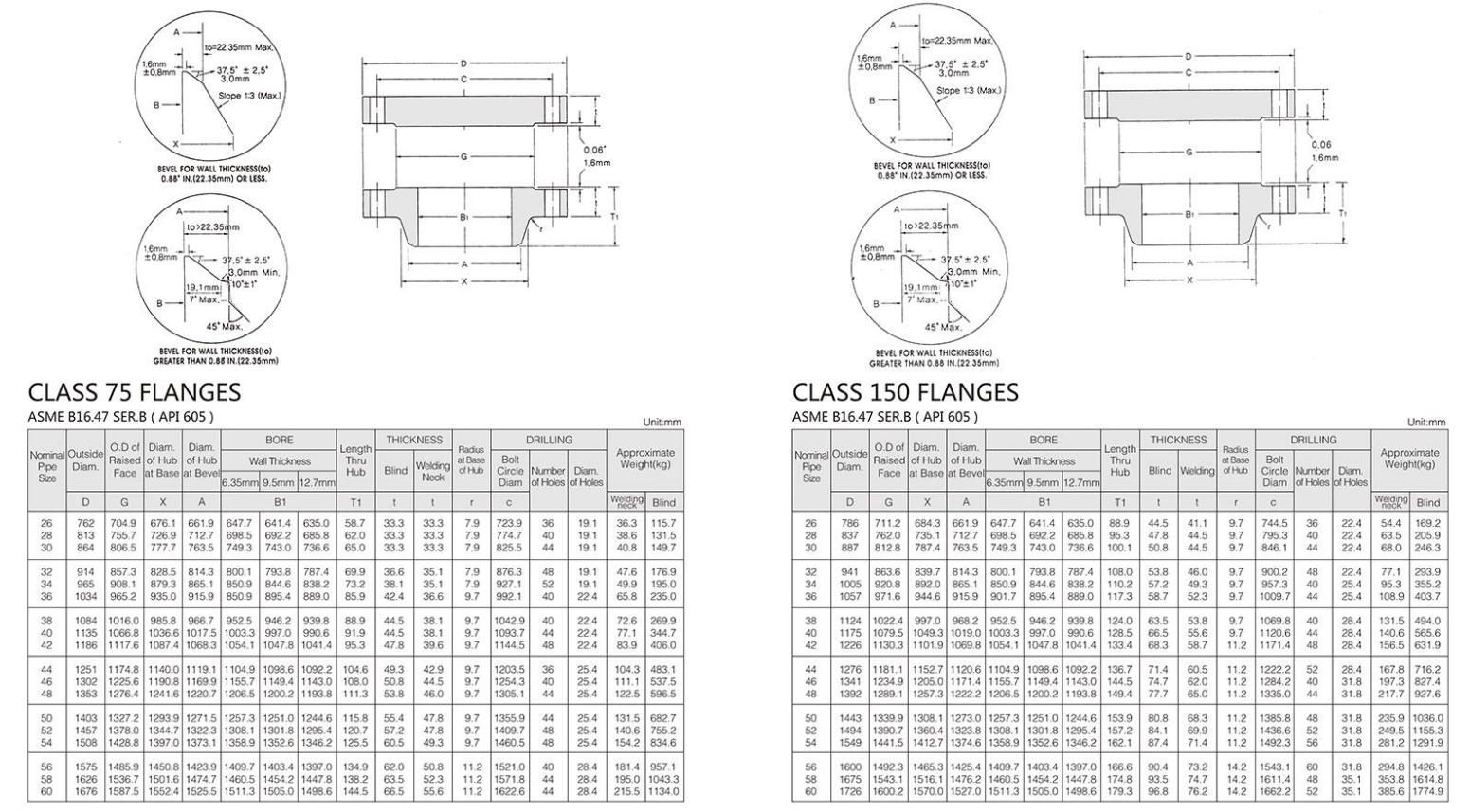

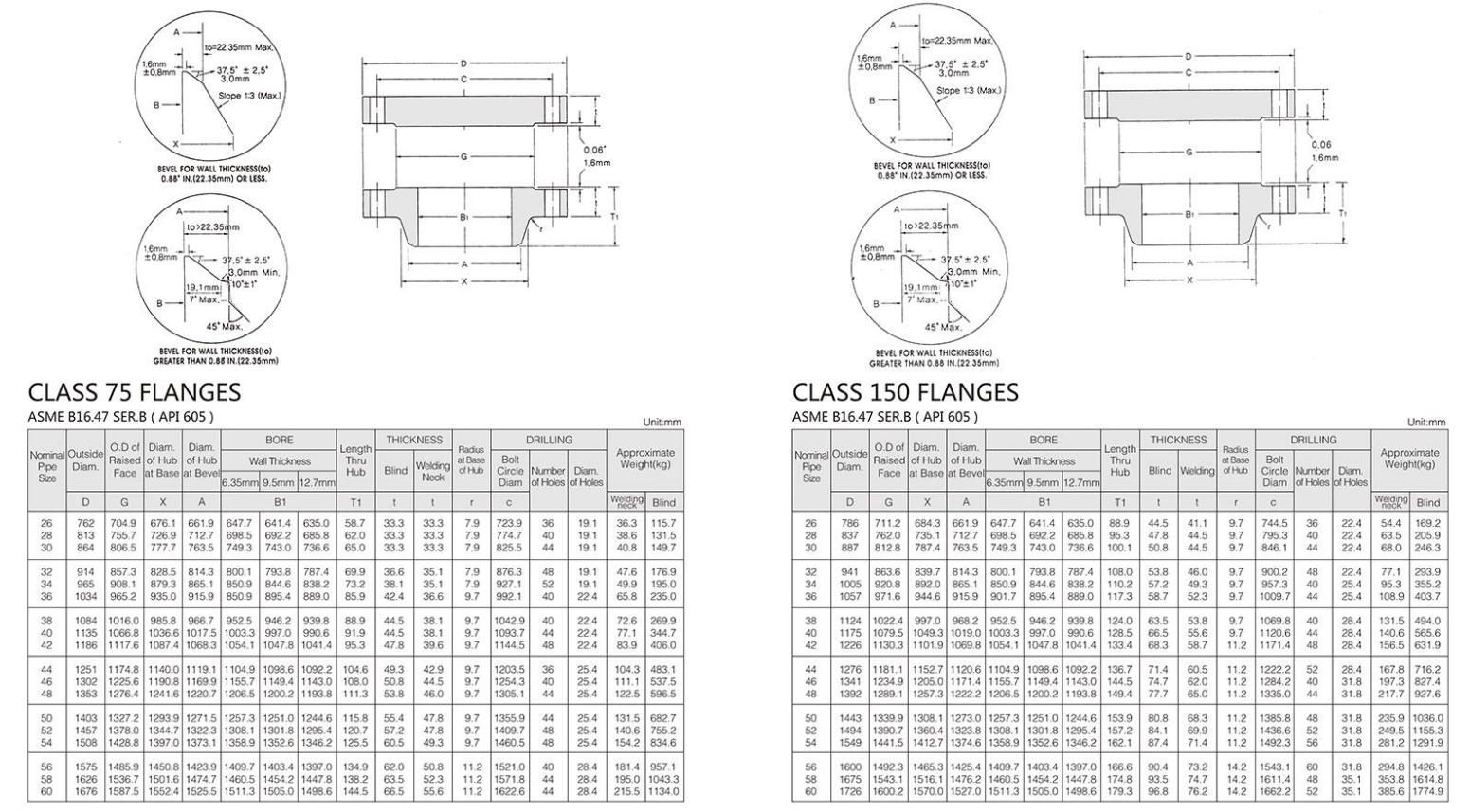

The choice of flange type valve depends on factors such as pressure rating, temperature, media compatibility, and operating environment. ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) standards dictate the dimensions and pressure classes for different types of flanges, ensuring safety and efficiency in industrial operations.

In addition to their functionality, flange type valves also provide advantages in terms of flexibility and adaptability. They can be easily connected to various pipe sizes and configurations due to the interchangeable nature of flanges. Moreover, they allow for easy access for inspection, cleaning, and replacement, reducing downtime and overall maintenance costs.

In conclusion, flange type valves are indispensable elements in numerous industrial processes due to their robust design, versatility, and ease of maintenance. Their importance lies not only in their ability to control fluid flow but also in their contribution to the overall efficiency and safety of the pipeline system. Understanding the specific features and applications of different flange type valves is crucial for optimal system performance and longevity.

flange type valve. Lastly, butterfly valves, with their disc-shaped closure member, are lightweight and cost-effective, making them suitable for low-pressure applications.

The choice of flange type valve depends on factors such as pressure rating, temperature, media compatibility, and operating environment. ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) standards dictate the dimensions and pressure classes for different types of flanges, ensuring safety and efficiency in industrial operations.

In addition to their functionality, flange type valves also provide advantages in terms of flexibility and adaptability. They can be easily connected to various pipe sizes and configurations due to the interchangeable nature of flanges. Moreover, they allow for easy access for inspection, cleaning, and replacement, reducing downtime and overall maintenance costs.

In conclusion, flange type valves are indispensable elements in numerous industrial processes due to their robust design, versatility, and ease of maintenance. Their importance lies not only in their ability to control fluid flow but also in their contribution to the overall efficiency and safety of the pipeline system. Understanding the specific features and applications of different flange type valves is crucial for optimal system performance and longevity.

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation

Ball valves, distinguished by their spherical closure member with a bore, offer quick shut-off capabilities and are often used in applications requiring frequent operation flange type valve. Lastly, butterfly valves, with their disc-shaped closure member, are lightweight and cost-effective, making them suitable for low-pressure applications.

The choice of flange type valve depends on factors such as pressure rating, temperature, media compatibility, and operating environment. ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) standards dictate the dimensions and pressure classes for different types of flanges, ensuring safety and efficiency in industrial operations.

In addition to their functionality, flange type valves also provide advantages in terms of flexibility and adaptability. They can be easily connected to various pipe sizes and configurations due to the interchangeable nature of flanges. Moreover, they allow for easy access for inspection, cleaning, and replacement, reducing downtime and overall maintenance costs.

In conclusion, flange type valves are indispensable elements in numerous industrial processes due to their robust design, versatility, and ease of maintenance. Their importance lies not only in their ability to control fluid flow but also in their contribution to the overall efficiency and safety of the pipeline system. Understanding the specific features and applications of different flange type valves is crucial for optimal system performance and longevity.

flange type valve. Lastly, butterfly valves, with their disc-shaped closure member, are lightweight and cost-effective, making them suitable for low-pressure applications.

The choice of flange type valve depends on factors such as pressure rating, temperature, media compatibility, and operating environment. ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) standards dictate the dimensions and pressure classes for different types of flanges, ensuring safety and efficiency in industrial operations.

In addition to their functionality, flange type valves also provide advantages in terms of flexibility and adaptability. They can be easily connected to various pipe sizes and configurations due to the interchangeable nature of flanges. Moreover, they allow for easy access for inspection, cleaning, and replacement, reducing downtime and overall maintenance costs.

In conclusion, flange type valves are indispensable elements in numerous industrial processes due to their robust design, versatility, and ease of maintenance. Their importance lies not only in their ability to control fluid flow but also in their contribution to the overall efficiency and safety of the pipeline system. Understanding the specific features and applications of different flange type valves is crucial for optimal system performance and longevity. Latest news

-

ANSI 150P SS304 SO FLANGE

NewsFeb.14,2025

-

ASTM A333GR6 STEEL PIPE

NewsJan.20,2025

-

ANSI B16.5 WELDING NECK FLANGE

NewsJan.15,2026

-

ANSI B16.5 SLIP-ON FLANGE

NewsApr.19,2024

-

SABS 1123 FLANGE

NewsJan.15,2025

-

DIN86044 PLATE FLANGE

NewsApr.19,2024

-

DIN2527 BLIND FLANGE

NewsApr.12,2024

-

JIS B2311 Butt-Welding Fittings LR/SR 45°/90° /180°Seamless/Weld

NewsApr.23,2024